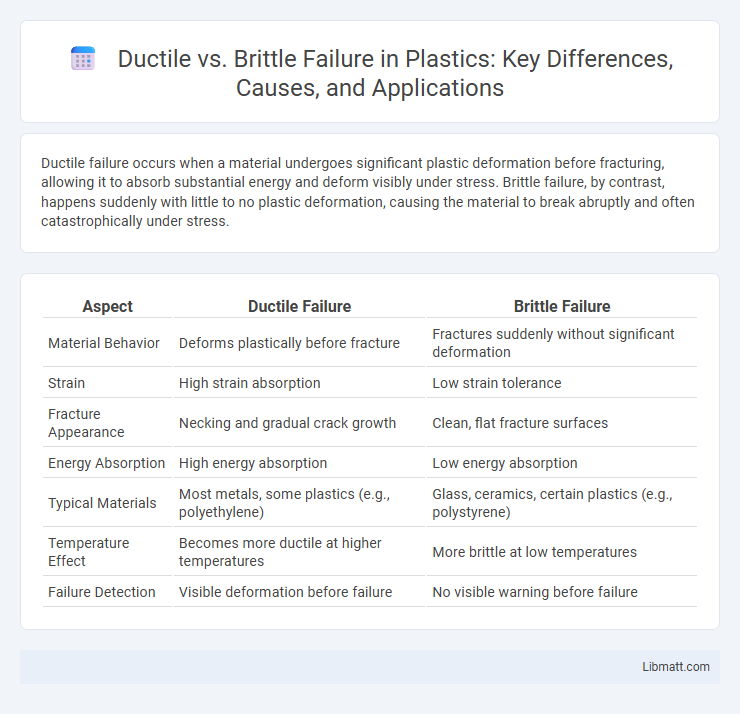

Ductile failure occurs when a material undergoes significant plastic deformation before fracturing, allowing it to absorb substantial energy and deform visibly under stress. Brittle failure, by contrast, happens suddenly with little to no plastic deformation, causing the material to break abruptly and often catastrophically under stress.

Table of Comparison

| Aspect | Ductile Failure | Brittle Failure |

|---|---|---|

| Material Behavior | Deforms plastically before fracture | Fractures suddenly without significant deformation |

| Strain | High strain absorption | Low strain tolerance |

| Fracture Appearance | Necking and gradual crack growth | Clean, flat fracture surfaces |

| Energy Absorption | High energy absorption | Low energy absorption |

| Typical Materials | Most metals, some plastics (e.g., polyethylene) | Glass, ceramics, certain plastics (e.g., polystyrene) |

| Temperature Effect | Becomes more ductile at higher temperatures | More brittle at low temperatures |

| Failure Detection | Visible deformation before failure | No visible warning before failure |

Introduction to Material Failure

Material failure occurs when a material can no longer withstand applied stress, leading to structural breakdown. Ductile failure involves significant plastic deformation before fracture, allowing warning signs such as stretching or necking, whereas brittle failure happens suddenly with little to no plastic deformation, causing rapid crack propagation. Understanding these mechanisms is crucial for predicting your material's behavior under different loading conditions to ensure safety and reliability.

Defining Ductile Failure

Ductile failure occurs when a material undergoes significant plastic deformation before fracturing, allowing it to absorb substantial energy under stress. This mode of failure is characterized by noticeable necking and the formation of microvoids that coalesce into cracks. Metals like mild steel typically exhibit ductile failure, which enhances structural safety by providing warning signs before complete material failure.

Understanding Brittle Failure

Brittle failure occurs when a material fractures suddenly without significant plastic deformation, typically under high-stress conditions or low temperatures. This type of failure is characterized by rapid crack propagation along specific crystallographic planes, producing a clean and sharp fracture surface. Understanding brittle failure is crucial in materials engineering to prevent catastrophic breakdowns in structural components such as ceramics, glass, and certain metals.

Key Differences Between Ductile and Brittle Failure

Ductile failure involves significant plastic deformation before fracturing, characterized by noticeable necking and energy absorption, whereas brittle failure occurs suddenly with minimal deformation and low energy absorption, often resulting in a clean fracture surface. Ductile materials exhibit high toughness and ductility, allowing them to withstand stress and strain, while brittle materials are prone to crack propagation and catastrophic failure under stress. Understanding these key differences helps you select appropriate materials and design components for safety and durability in engineering applications.

Factors Influencing Failure Modes

Material composition, temperature, strain rate, and microstructure primarily influence whether a material undergoes ductile or brittle failure. Higher temperatures and slower strain rates tend to promote ductile behavior, allowing materials to deform plastically before fracturing. Conversely, low temperatures, high strain rates, and the presence of stress concentrators or impurities favor brittle failure by causing sudden fracture without significant deformation.

Visual and Mechanical Signs of Failure

Ductile failure is characterized by significant plastic deformation and noticeable elongation or necking before fracture, often accompanied by rough, fibrous fracture surfaces. Brittle failure shows minimal plastic deformation with sudden fracture, featuring smooth, shiny, or granular surfaces and sharp crack propagation patterns. Your ability to distinguish these visual and mechanical signs is crucial for diagnosing material performance under stress.

Common Materials Exhibiting Ductile or Brittle Failure

Common materials exhibiting ductile failure include metals like copper, aluminum, and mild steel, known for their ability to undergo significant plastic deformation before fracturing. Brittle failure is characteristic of materials such as cast iron, glass, and ceramics, which fracture suddenly with little to no plastic deformation under stress. Understanding these material behaviors helps you select appropriate materials in engineering applications where failure mode impacts safety and performance.

Real-World Examples and Case Studies

Ductile failure is commonly observed in materials like mild steel in structural components, where significant deformation occurs before fracture, exemplified by bridge collapses that unfold gradually, allowing for warning signs. Brittle failure, seen in materials like cast iron or glass, happens suddenly without noticeable deformation, as demonstrated by the sudden fracture of glass windows during impact or the catastrophic failure of brittle bolts in aerospace applications. Understanding these real-world examples helps you select appropriate materials and design safety measures to prevent unexpected structural failures.

Prevention and Control of Material Failure

Effective prevention and control of material failure in ductile and brittle materials involves selecting appropriate materials with favorable mechanical properties, such as high toughness for ductile failure and increased fracture resistance for brittle failure. Implementing proper design factors, including stress concentration minimization and adequate safety margins, reduces the risk of unexpected failure under operational loads. Regular inspection techniques, non-destructive testing (NDT), and controlled loading conditions further enhance structural integrity and lifespan, preventing catastrophic failures in engineering applications.

Conclusion: Choosing Materials Based on Failure Characteristics

Selecting materials based on failure characteristics requires understanding ductile failure's ability to absorb significant energy through plastic deformation before fracturing, making ductile materials ideal for applications demanding high toughness and safety. Brittle failure, characterized by sudden fracture with minimal deformation, suits materials used where rigidity and hardness are critical but catastrophic failure risks are minimized. Engineers prioritize ductile materials in structural applications to prevent abrupt collapse, while brittle materials often serve in wear-resistant and high-strength components.

Ductile vs Brittle Failure Infographic

libmatt.com

libmatt.com