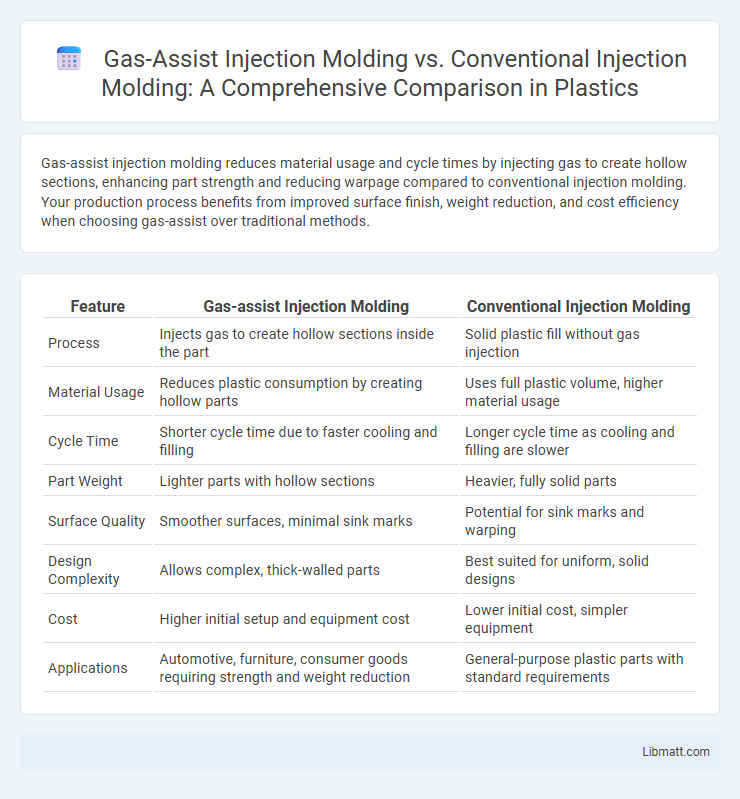

Gas-assist injection molding reduces material usage and cycle times by injecting gas to create hollow sections, enhancing part strength and reducing warpage compared to conventional injection molding. Your production process benefits from improved surface finish, weight reduction, and cost efficiency when choosing gas-assist over traditional methods.

Table of Comparison

| Feature | Gas-assist Injection Molding | Conventional Injection Molding |

|---|---|---|

| Process | Injects gas to create hollow sections inside the part | Solid plastic fill without gas injection |

| Material Usage | Reduces plastic consumption by creating hollow parts | Uses full plastic volume, higher material usage |

| Cycle Time | Shorter cycle time due to faster cooling and filling | Longer cycle time as cooling and filling are slower |

| Part Weight | Lighter parts with hollow sections | Heavier, fully solid parts |

| Surface Quality | Smoother surfaces, minimal sink marks | Potential for sink marks and warping |

| Design Complexity | Allows complex, thick-walled parts | Best suited for uniform, solid designs |

| Cost | Higher initial setup and equipment cost | Lower initial cost, simpler equipment |

| Applications | Automotive, furniture, consumer goods requiring strength and weight reduction | General-purpose plastic parts with standard requirements |

Introduction to Injection Molding Technologies

Gas-assist injection molding utilizes pressurized gas to create hollow sections within molded parts, reducing material usage and cycle times compared to conventional injection molding, which relies solely on molten plastic injected into a mold cavity. This advanced technology improves part strength, reduces warpage, and allows for larger, more complex designs with enhanced dimensional stability. Your manufacturing process benefits from increased efficiency and cost savings when selecting gas-assist injection molding over traditional methods.

Overview of Conventional Injection Molding

Conventional injection molding involves injecting molten plastic directly into a mold cavity to form a part, offering precise dimensional control and high production rates for complex shapes. This method excels in producing solid or hollow parts with consistent mechanical properties, utilizing materials such as thermoplastics, thermosets, and elastomers. Your manufacturing efficiency benefits from its simplified process and widespread applicability across automotive, consumer goods, and electronics industries.

Fundamentals of Gas-assist Injection Molding

Gas-assist injection molding injects pressurized gas into the molten plastic during the molding process, creating hollow sections within the part to reduce weight and material usage. This technique improves dimensional stability, reduces warp, and shortens cycle times compared to conventional injection molding, where the entire cavity is filled with solid plastic. Your production efficiency benefits from enhanced strength-to-weight ratio and cost savings enabled by the precise control of gas injection parameters in gas-assist molding.

Key Differences Between Gas-assist and Conventional Methods

Gas-assist injection molding uses pressurized gas to hollow out thick sections of molded parts, reducing material usage and cycle time, while conventional injection molding fills the entire mold cavity with molten plastic. Your choice influences weight reduction, surface finish quality, and design flexibility, with gas-assist providing better structural integrity in complex parts due to minimized sink marks and warpage. Productivity improvements and cost savings are significant in gas-assist processes compared to traditional methods, especially for large, thick components.

Advantages of Gas-assist Injection Molding

Gas-assist injection molding offers significant advantages over conventional injection molding by reducing part weight and material usage through hollow or partially hollow structures, leading to cost savings and enhanced strength-to-weight ratios. It improves cycle times due to faster cooling by creating uniform wall thickness and reduces warpage and residual stresses, resulting in higher dimensional accuracy and superior surface finish. The process also enables the production of complex geometries that are difficult to achieve with conventional methods, enhancing design flexibility and overall product quality.

Limitations of Gas-assist vs. Conventional Injection Molding

Gas-assist injection molding faces limitations such as higher tooling costs and complexity compared to conventional injection molding, which can increase production expenses. This technique may also struggle with producing parts that require intricate internal geometries or very thin walls, areas where conventional injection molding excels. Your choice between these methods should consider the balance between material savings and design flexibility, as conventional injection molding offers more versatility in part complexity.

Material Compatibility and Selection Criteria

Gas-assist injection molding excels with materials like ABS, polycarbonate, and polypropylene, offering enhanced dimensional stability and reduced warpage compared to conventional injection molding, which is compatible with a broader range of thermoplastics including nylon and polyethylene. Your material selection should consider factors such as part thickness, desired surface finish, and mechanical properties, as gas-assist technique favors thicker, more rigid parts with hollow sections to optimize weight and cost savings. Understanding the compatibility of the chosen polymer with gas penetration and the part's functional requirements ensures optimal performance in both molding processes.

Design Considerations for Each Molding Process

Gas-assist injection molding requires design considerations such as uniform wall thickness to facilitate consistent gas flow and avoid defects like sink marks or voids, while conventional injection molding allows for more variable wall thickness but demands thicker sections to manage shrinkage and warping. Part geometry in gas-assist molding should include hollow or ribbed structures to optimize gas penetration and reduce material usage, contrasting with conventional molding which often needs solid, robust designs to maintain structural integrity. Mold venting and gating locations are critical in gas-assist processes to ensure efficient gas escape and cavity filling, whereas conventional molding relies heavily on optimized gate size and placement to prevent weld lines and ensure proper material flow.

Cost Implications and Production Efficiency

Gas-assist injection molding significantly reduces material costs by using nitrogen gas to hollow out thick sections, resulting in lighter parts and less plastic resin consumption compared to conventional injection molding. Production efficiency improves with faster cycle times and reduced cooling phases in gas-assist processes, allowing higher throughput and lower energy expenses. Your manufacturing budget benefits from decreased raw material usage and streamlined production, making gas-assist molding a cost-effective alternative in high-volume or complex part fabrication.

Applications and Industry Use Cases

Gas-assist injection molding is widely used in automotive parts manufacturing, consumer electronics enclosures, and furniture components due to its ability to produce lightweight, hollow, yet strong structures with improved material savings. Conventional injection molding remains dominant in high-volume production of solid plastic parts such as household goods, packaging, and medical devices where uniform density and strength are critical. Industries like automotive, electronics, and appliances increasingly adopt gas-assist molding to reduce cycle time and weight, while conventional molding continues to serve applications requiring dense, intricate, and highly detailed plastic parts.

Gas-assist Injection Molding vs Conventional Injection Molding Infographic

libmatt.com

libmatt.com