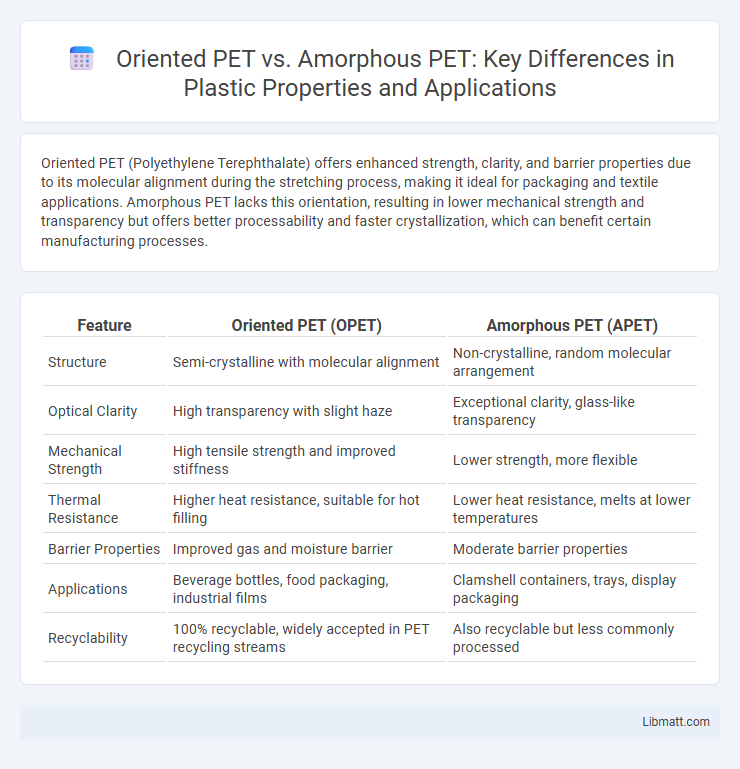

Oriented PET (Polyethylene Terephthalate) offers enhanced strength, clarity, and barrier properties due to its molecular alignment during the stretching process, making it ideal for packaging and textile applications. Amorphous PET lacks this orientation, resulting in lower mechanical strength and transparency but offers better processability and faster crystallization, which can benefit certain manufacturing processes.

Table of Comparison

| Feature | Oriented PET (OPET) | Amorphous PET (APET) |

|---|---|---|

| Structure | Semi-crystalline with molecular alignment | Non-crystalline, random molecular arrangement |

| Optical Clarity | High transparency with slight haze | Exceptional clarity, glass-like transparency |

| Mechanical Strength | High tensile strength and improved stiffness | Lower strength, more flexible |

| Thermal Resistance | Higher heat resistance, suitable for hot filling | Lower heat resistance, melts at lower temperatures |

| Barrier Properties | Improved gas and moisture barrier | Moderate barrier properties |

| Applications | Beverage bottles, food packaging, industrial films | Clamshell containers, trays, display packaging |

| Recyclability | 100% recyclable, widely accepted in PET recycling streams | Also recyclable but less commonly processed |

Introduction to Oriented PET and Amorphous PET

Oriented PET (Polyethylene Terephthalate) is a type of polyester characterized by its molecular chains aligned in a specific direction, resulting in enhanced strength, clarity, and thermal resistance compared to Amorphous PET, which lacks this ordered molecular structure. Amorphous PET possesses a random molecular arrangement, offering increased transparency and flexibility but lower mechanical strength and heat resistance than Oriented PET. Understanding the differences between these two forms helps you select the appropriate material for applications requiring specific mechanical and optical properties.

Chemical Structure Differences

Oriented PET (polyethylene terephthalate) exhibits a highly ordered molecular arrangement with polymer chains aligned in a specific direction, enhancing its tensile strength and barrier properties. In contrast, Amorphous PET lacks this ordered structure, featuring randomly arranged polymer chains that result in greater transparency and flexibility but lower mechanical strength. The chemical backbone remains identical, yet the difference in molecular orientation directly influences the material's physical and thermal characteristics.

Manufacturing Processes Explained

Oriented PET (Polyethylene Terephthalate) undergoes a manufacturing process involving stretching the polymer film in one or two directions to align the molecular chains, resulting in improved strength, clarity, and barrier properties. Amorphous PET is produced by rapid cooling and solidification, preventing molecular orientation and yielding a transparent, flexible material with lower crystallinity. Understanding these differences in manufacturing processes helps optimize Your choice between durability and flexibility for specific applications like packaging or fibers.

Physical Properties Comparison

Oriented PET exhibits higher tensile strength, improved dimensional stability, and greater clarity compared to amorphous PET due to its highly ordered molecular structure. Amorphous PET, characterized by a random molecular arrangement, offers better impact resistance and is easier to thermoform but has lower mechanical strength and heat resistance. The crystalline orientation in oriented PET results in enhanced barrier properties against gases and moisture, making it more suitable for packaging applications where durability and protection are critical.

Mechanical Strength and Durability

Oriented PET (Polyethylene Terephthalate) exhibits significantly higher mechanical strength and durability compared to amorphous PET due to its molecular alignment process, which enhances tensile strength and impact resistance. This orientation results in improved dimensional stability and greater resistance to stress cracking, making oriented PET ideal for applications requiring robust structural integrity. In contrast, amorphous PET lacks this molecular order, leading to lower mechanical strength and reduced long-term durability under mechanical stress.

Optical Clarity and Appearance

Oriented PET (Polyethylene Terephthalate) exhibits superior optical clarity and a glossy appearance due to the alignment of polymer chains during stretching, reducing light scattering and enhancing transparency. In contrast, Amorphous PET lacks this molecular orientation, resulting in a more hazy or cloudy look with lower light transmission. The distinct difference in molecular structure between oriented and amorphous PET directly influences their visual quality, making oriented PET preferable for applications requiring high clarity.

Applications in Industry

Oriented PET (OPET) offers high tensile strength and clarity, making it ideal for packaging films, magnetic tapes, and bottle manufacturing where durability and barrier properties are critical. Amorphous PET, with its lower crystallinity, is commonly used in applications requiring transparency and flexibility such as single-use containers and cosmetic packaging. Your choice between Oriented and Amorphous PET depends on whether the industry prioritizes mechanical strength or optical clarity for specific product applications.

Environmental Impact and Recycling

Oriented PET (OPET) has a more crystalline structure, making it stronger and more resistant to heat but slightly more challenging to recycle than Amorphous PET (APET), which is less crystalline and easier to reprocess. Your choice between OPET and APET affects environmental impact, as APET typically requires less energy for recycling and produces fewer emissions during the process. Both types contribute to sustainable packaging when recycled properly, but APET offers a more eco-friendly option due to its simpler recycling stream and enhanced compatibility with existing recycling facilities.

Cost Analysis and Market Trends

Oriented PET (OPET) generally incurs higher production costs due to the additional processing steps like stretching and heat-setting, which enhance its mechanical properties and clarity, making it ideal for high-performance packaging applications. In contrast, Amorphous PET (APET) offers a more cost-effective solution with simpler processing and adequate clarity for less demanding packaging needs, driving its strong presence in budget-conscious markets. You can expect market trends to favor OPET in premium sectors like food and pharmaceutical packaging, while APET maintains a solid share in cost-sensitive segments, reflecting a balance between performance and affordability.

Choosing Between Oriented PET and Amorphous PET

Choosing between oriented PET (polyethylene terephthalate) and amorphous PET depends on the application's requirements for strength, clarity, and thermal properties. Oriented PET, produced through biaxial stretching, offers superior tensile strength, dimensional stability, and improved barrier properties, making it ideal for packaging and industrial uses. Amorphous PET provides excellent optical clarity and flexibility but has lower mechanical strength and heat resistance, suited for applications like cosmetic containers and food packaging where transparency is paramount.

Oriented PET vs Amorphous PET Infographic

libmatt.com

libmatt.com