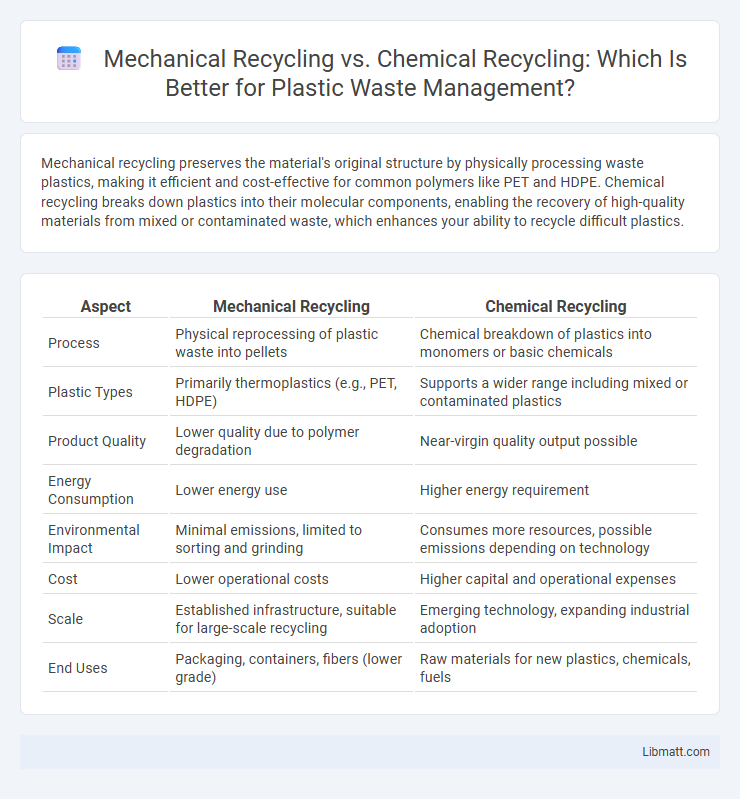

Mechanical recycling preserves the material's original structure by physically processing waste plastics, making it efficient and cost-effective for common polymers like PET and HDPE. Chemical recycling breaks down plastics into their molecular components, enabling the recovery of high-quality materials from mixed or contaminated waste, which enhances your ability to recycle difficult plastics.

Table of Comparison

| Aspect | Mechanical Recycling | Chemical Recycling |

|---|---|---|

| Process | Physical reprocessing of plastic waste into pellets | Chemical breakdown of plastics into monomers or basic chemicals |

| Plastic Types | Primarily thermoplastics (e.g., PET, HDPE) | Supports a wider range including mixed or contaminated plastics |

| Product Quality | Lower quality due to polymer degradation | Near-virgin quality output possible |

| Energy Consumption | Lower energy use | Higher energy requirement |

| Environmental Impact | Minimal emissions, limited to sorting and grinding | Consumes more resources, possible emissions depending on technology |

| Cost | Lower operational costs | Higher capital and operational expenses |

| Scale | Established infrastructure, suitable for large-scale recycling | Emerging technology, expanding industrial adoption |

| End Uses | Packaging, containers, fibers (lower grade) | Raw materials for new plastics, chemicals, fuels |

Introduction to Plastic Recycling Methods

Mechanical recycling involves the physical reprocessing of plastic waste by sorting, washing, shredding, and melting to produce new plastic materials, primarily preserving the polymer's original structure. Chemical recycling breaks down plastic polymers into their chemical building blocks through processes like pyrolysis or depolymerization, enabling the production of virgin-quality plastics or fuels. Both methods address plastic waste management but differ in energy consumption, product quality, and scalability within the sustainable recycling industry.

What is Mechanical Recycling?

Mechanical recycling involves the process of collecting, sorting, cleaning, and physically processing plastic waste into new raw materials without altering the chemical structure. This method typically includes shredding, melting, and remolding plastics to produce reusable pellets or products. Mechanical recycling is cost-effective and widely used for common plastics like PET and HDPE but may degrade material quality after multiple cycles.

What is Chemical Recycling?

Chemical recycling is an advanced process that breaks down plastic waste into its basic chemical components, enabling the production of new plastics with properties close to virgin materials. Unlike mechanical recycling, which physically grinds and remelts plastics, chemical recycling uses methods such as pyrolysis, depolymerization, or solvolysis to convert polymers into monomers or fuel. This approach helps handle contaminated or mixed plastic streams that are challenging for traditional recycling, supporting a more circular economy in plastic waste management.

Key Differences Between Mechanical and Chemical Recycling

Mechanical recycling involves physically processing plastic waste by sorting, washing, shredding, and melting it to produce new plastic products without altering the polymer's chemical structure. Chemical recycling breaks down plastic polymers at a molecular level into monomers or other basic chemicals through processes like pyrolysis, gasification, or depolymerization, enabling the production of virgin-quality plastics. The primary differences lie in mechanical recycling's limitation to certain plastic types and degradation of material quality versus chemical recycling's ability to handle mixed or contaminated plastics and restore original polymer properties.

Advantages of Mechanical Recycling

Mechanical recycling preserves the original polymer structure, allowing materials like PET and HDPE to be efficiently reprocessed with minimal energy consumption compared to chemical recycling. This method reduces greenhouse gas emissions by avoiding complex chemical processes and supports circular economy goals through cost-effective recovery of plastics for packaging and consumer goods. High scalability and lower operational costs make mechanical recycling a preferred solution for managing post-consumer plastic waste streams.

Advantages of Chemical Recycling

Chemical recycling offers significant advantages by breaking down plastics into their original monomers, enabling the production of new materials with the same quality as virgin plastics. This process can handle mixed or contaminated plastics that mechanical recycling cannot efficiently process, expanding your recycling capabilities. Additionally, chemical recycling reduces plastic waste accumulation and carbon emissions, contributing to a more sustainable circular economy.

Limitations and Challenges of Mechanical Recycling

Mechanical recycling faces limitations such as the degradation of polymer quality due to repeated melting and processing, which reduces material performance and restricts applications. Contamination from mixed plastics, additives, and dyes complicates sorting and processing, leading to lower purity and recycled material value. The process also struggles with complex or multi-layered packaging, making chemical recycling a necessary alternative for resolving these challenges.

Limitations and Challenges of Chemical Recycling

Chemical recycling faces significant limitations such as high energy consumption, complex processes, and costly infrastructure, which impact its scalability and economic viability. Contamination in plastic waste streams poses challenges for chemical recycling efficiency and product quality, often requiring extensive pre-treatment. Your choice between mechanical and chemical recycling should consider these challenges alongside the environmental benefits and practical feasibility.

Environmental Impact: Mechanical vs Chemical Recycling

Mechanical recycling reduces landfill waste by physically processing plastics without altering their chemical structure, resulting in lower energy consumption and fewer greenhouse gas emissions compared to chemical recycling. Chemical recycling, by breaking down polymers into monomers for reuse, can handle contaminated or mixed plastics but typically requires higher energy input and generates more emissions. Evaluating environmental impact, mechanical recycling offers a more sustainable footprint for clean, sorted materials, while chemical recycling provides a viable solution for plastic waste that is otherwise non-recyclable mechanically.

Future Trends in Plastic Recycling Technologies

Future trends in plastic recycling technologies emphasize the advancement of chemical recycling methods that break down polymers into their monomers for higher-quality material recovery, complementing traditional mechanical recycling processes. Innovations in catalytic depolymerization and enzymatic degradation are poised to enhance the efficiency and scalability of chemical recycling, addressing the limitations of sorting contamination and polymer degradation faced by mechanical recycling. Your sustainable efforts will benefit from integrated recycling systems that combine both mechanical and chemical approaches to maximize plastic waste valorization and support circular economy goals.

Mechanical Recycling vs Chemical Recycling Infographic

libmatt.com

libmatt.com