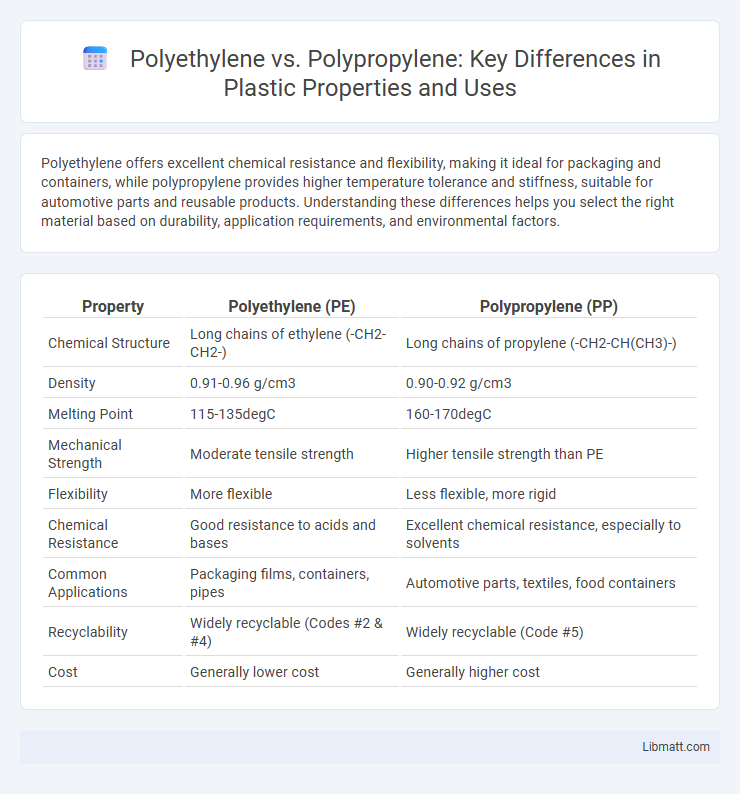

Polyethylene offers excellent chemical resistance and flexibility, making it ideal for packaging and containers, while polypropylene provides higher temperature tolerance and stiffness, suitable for automotive parts and reusable products. Understanding these differences helps you select the right material based on durability, application requirements, and environmental factors.

Table of Comparison

| Property | Polyethylene (PE) | Polypropylene (PP) |

|---|---|---|

| Chemical Structure | Long chains of ethylene (-CH2-CH2-) | Long chains of propylene (-CH2-CH(CH3)-) |

| Density | 0.91-0.96 g/cm3 | 0.90-0.92 g/cm3 |

| Melting Point | 115-135degC | 160-170degC |

| Mechanical Strength | Moderate tensile strength | Higher tensile strength than PE |

| Flexibility | More flexible | Less flexible, more rigid |

| Chemical Resistance | Good resistance to acids and bases | Excellent chemical resistance, especially to solvents |

| Common Applications | Packaging films, containers, pipes | Automotive parts, textiles, food containers |

| Recyclability | Widely recyclable (Codes #2 & #4) | Widely recyclable (Code #5) |

| Cost | Generally lower cost | Generally higher cost |

Introduction to Polyethylene and Polypropylene

Polyethylene and Polypropylene are two of the most widely used thermoplastic polymers in manufacturing due to their versatile properties and cost-effectiveness. Polyethylene is known for its excellent chemical resistance, flexibility, and impact strength, making it ideal for packaging films, containers, and pipes. Polypropylene offers higher rigidity, better fatigue resistance, and a higher melting point, which suits applications such as automotive parts, textiles, and reusable containers, helping you choose the right material for your specific needs.

Chemical Structure and Composition

Polyethylene (PE) is composed of repeated ethylene monomers with a simple linear or branched hydrocarbon chain, making it highly flexible and chemically resistant. Polypropylene (PP) consists of propylene monomers featuring a methyl group attached to the polymer backbone, contributing to its higher rigidity and melting point compared to polyethylene. Understanding these differences in chemical structure helps you select the right polymer for specific applications based on mechanical strength and thermal properties.

Manufacturing Processes Compared

Polyethylene (PE) is primarily produced through radical polymerization processes such as high-pressure polymerization for low-density polyethylene (LDPE) and catalytic polymerization for high-density polyethylene (HDPE), while polypropylene (PP) is synthesized mainly via Ziegler-Natta or metallocene catalyst systems at moderate pressures and temperatures. The manufacturing of PE typically involves processes like gas-phase, slurry, or solution polymerization, which influence the polymer's density and branching. In contrast, PP's production focuses on controlling isotacticity and tacticity through catalyst selection, impacting crystallinity and mechanical properties.

Physical Properties: Strength and Flexibility

Polyethylene offers excellent flexibility and impact resistance, making it ideal for applications requiring durability and resilience. Polypropylene exhibits higher tensile strength and greater rigidity, suitable for products needing structural stability and resistance to deformation. Understanding these differences helps you choose the right polymer based on the balance between strength and flexibility required for your project.

Thermal and Chemical Resistance

Polyethylene exhibits excellent chemical resistance to acids, bases, and solvents, making it suitable for various industrial applications, but its thermal resistance is moderate, typically withstanding temperatures up to 80degC. Polypropylene offers higher thermal resistance, maintaining structural integrity up to 130degC, and demonstrates strong resistance to many chemicals, including alkalis and organic solvents. Both polymers resist moisture absorption, but polypropylene's superior thermal endurance makes it preferable for applications involving higher temperature exposure.

Common Applications of Polyethylene

Polyethylene is widely used in packaging materials such as plastic bags, films, and containers due to its flexibility and durability. It also serves in household goods, toys, and automotive components, benefiting from its resistance to moisture and chemicals. Your choice of polyethylene for these applications ensures lightweight and cost-effective solutions with excellent performance characteristics.

Key Uses of Polypropylene

Polypropylene is widely used in packaging, automotive components, textiles, and consumer goods due to its strong chemical resistance, flexibility, and durability. Its applications range from food containers and medical devices to car parts and household items, making it a versatile polymer in various industries. You can rely on polypropylene for cost-effective, lightweight, and heat-resistant materials.

Environmental Impact and Recyclability

Polyethylene (PE) and Polypropylene (PP) differ significantly in environmental impact and recyclability, with PE generally having a lower carbon footprint due to its simpler molecular structure and higher recyclability rates in municipal programs. PE is widely recycled into plastic bags, containers, and films, whereas PP is recycled into automotive parts, textiles, and packaging, though its recycling infrastructure is less developed. Both materials contribute to plastic pollution, but advancements in chemical recycling and biodegradable alternatives are improving their sustainability profiles.

Cost Comparison and Market Availability

Polyethylene (PE) generally costs less than polypropylene (PP) due to its simpler manufacturing process and wider global production scale. Market availability favors polyethylene, as it is produced in larger volumes and used extensively in packaging, containers, and films. Your choice may depend on balancing the lower cost and higher availability of PE against the specific performance properties offered by polypropylene.

Choosing the Right Polymer for Your Needs

Polyethylene offers excellent chemical resistance and flexibility, making it ideal for packaging, containers, and plastic bags, whereas Polypropylene provides higher stiffness and heat resistance, suitable for automotive parts, textiles, and thermal containers. Your choice depends on whether you prioritize durability and thermal stability or flexibility and chemical resistance. Evaluating specific application requirements like temperature range, mechanical strength, and environmental exposure helps determine the best polymer for your needs.

Polyethylene vs Polypropylene Infographic

libmatt.com

libmatt.com