Gas-assisted molding uses pressurized gas to create hollow sections in plastic parts, reducing weight and material usage, while water-assisted molding employs high-pressure water to achieve similar hollow structures with faster cooling times and improved surface finish. Your choice depends on requirements for cycle time, surface quality, and environmental considerations, as gas-assisted molding offers better control over complex geometries and water-assisted molding enhances part strength and reduces warpage.

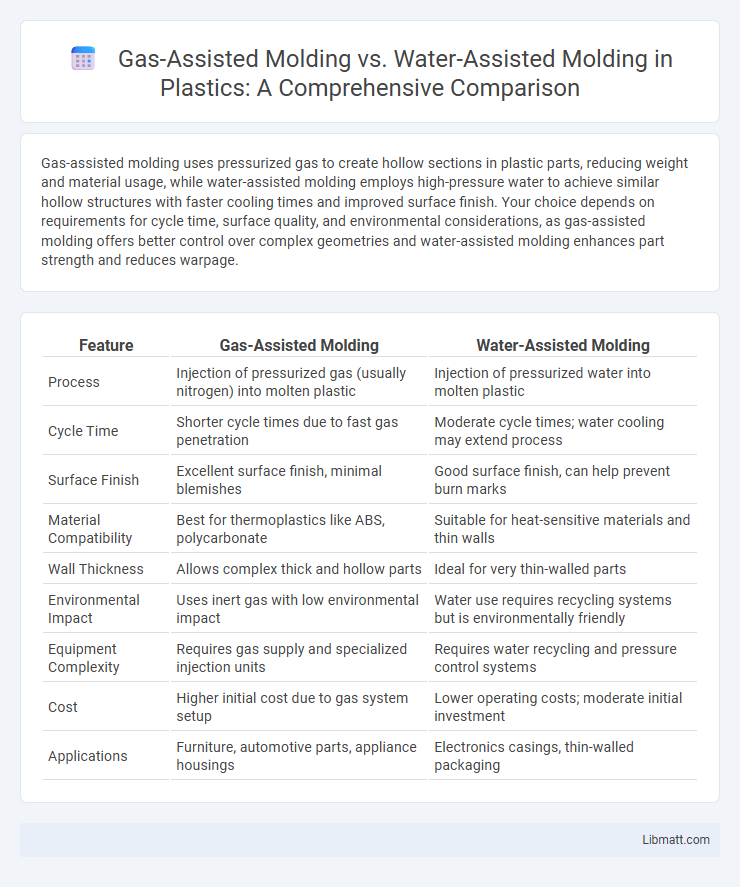

Table of Comparison

| Feature | Gas-Assisted Molding | Water-Assisted Molding |

|---|---|---|

| Process | Injection of pressurized gas (usually nitrogen) into molten plastic | Injection of pressurized water into molten plastic |

| Cycle Time | Shorter cycle times due to fast gas penetration | Moderate cycle times; water cooling may extend process |

| Surface Finish | Excellent surface finish, minimal blemishes | Good surface finish, can help prevent burn marks |

| Material Compatibility | Best for thermoplastics like ABS, polycarbonate | Suitable for heat-sensitive materials and thin walls |

| Wall Thickness | Allows complex thick and hollow parts | Ideal for very thin-walled parts |

| Environmental Impact | Uses inert gas with low environmental impact | Water use requires recycling systems but is environmentally friendly |

| Equipment Complexity | Requires gas supply and specialized injection units | Requires water recycling and pressure control systems |

| Cost | Higher initial cost due to gas system setup | Lower operating costs; moderate initial investment |

| Applications | Furniture, automotive parts, appliance housings | Electronics casings, thin-walled packaging |

Introduction to Gas-Assisted and Water-Assisted Molding

Gas-assisted molding uses pressurized gas, typically nitrogen, to create hollow sections in plastic parts, improving material distribution and reducing cycle time. Water-assisted molding employs high-pressure water to form internal channels, enabling rapid cooling and complex geometries. Your choice depends on requirements such as wall thickness, cooling efficiency, and environmental considerations.

Fundamental Principles of Assisted Injection Molding

Gas-assisted molding involves injecting inert gas, typically nitrogen, into the molten plastic to create hollow sections, reducing material use and cycle time while improving part strength and surface quality. Water-assisted molding uses high-pressure water to form internal channels within the plastic, enhancing cooling rates and reducing warpage in complex geometries. Both techniques optimize injection molding by improving internal structure control, minimizing defects, and enabling lightweight designs with enhanced mechanical properties.

Key Differences Between Gas and Water-Assisted Processes

Gas-assisted molding uses nitrogen gas to create hollow sections within plastic parts, resulting in reduced material usage and lower cycle times, while water-assisted molding employs high-pressure water to achieve similar hollow features with improved surface finish and reduced warpage. Gas-assisted processes excel in producing complex geometries with greater dimensional stability, whereas water-assisted molding offers advantages in environmental safety and faster solidification due to water's higher thermal conductivity. Your choice depends on factors like specific part requirements, environmental considerations, and production efficiency goals.

Material Compatibility and Selection Criteria

Gas-assisted molding is well-suited for thermoplastics like polypropylene, polyethylene, and acrylonitrile butadiene styrene (ABS) due to its ability to create hollow sections and reduce material usage; it excels in applications requiring dimensional stability and lightweight parts. Water-assisted molding, compatible with similar polymers but especially beneficial for engineering plastics such as polyamides and polycarbonate, offers superior surface finish and faster cooling times by utilizing water to displace molten material. Selection criteria hinge on material properties like thermal conductivity and melt flow index, desired part complexity, and application-specific performance requirements including strength, weight reduction, and cycle time efficiency.

Process Efficiency and Cycle Time Comparison

Gas-assisted molding offers superior process efficiency and reduced cycle times compared to water-assisted molding due to the lower viscosity and higher compressibility of gas, allowing for faster mold filling and cooling. Water-assisted molding involves slower filling speeds and longer cycle times because of the incompressible nature of water, which increases hydraulic pressure and cooling duration. Studies demonstrate that gas-assisted molding can cut cycle times by up to 30%, enhancing productivity in complex part manufacturing.

Quality and Surface Finish of Molded Parts

Gas-assisted molding produces molded parts with smoother surfaces and fewer sink marks due to the controlled gas pressure that uniformly pushes the molten plastic against the mold walls. Water-assisted molding often yields superior internal part strength and reduced cycle times, but may result in less consistent surface finish quality due to potential moisture-induced imperfections. Optimizing process parameters in gas-assisted molding significantly enhances the aesthetic and structural quality of the final parts compared to water-assisted techniques.

Design Flexibility and Part Complexity

Gas-assisted molding enables greater design flexibility by allowing the creation of hollow, lightweight parts with complex geometries and uniform wall thickness, reducing sink marks and warpage. Water-assisted molding excels in producing parts with intricate internal channels and enhanced cooling efficiency, supporting complex internal structures impossible with traditional molding methods. Both technologies expand the possibilities for advanced automotive, medical, and consumer product components requiring sophisticated design and high structural integrity.

Cost Implications and Production Scalability

Gas-assisted molding typically incurs higher initial costs due to specialized gas injection equipment but offers lower material waste and cycle times, improving long-term cost efficiency. Water-assisted molding requires robust corrosion-resistant systems, leading to increased maintenance costs, though it can achieve faster cooling rates and higher throughput for thin-walled parts. Production scalability in gas-assisted molding benefits from consistent cavity filling in complex geometries, while water-assisted molding excels in scaling up for large-volume runs where rapid cooling and cycle time reduction are priorities.

Typical Applications in Various Industries

Gas-assisted molding is widely used in automotive and consumer electronics industries for creating complex, lightweight plastic parts with hollow sections, improving structural strength while reducing material usage. Water-assisted molding finds applications in medical device manufacturing and food packaging, where precise control of wall thickness and surface finish are critical for product hygiene and performance. Your choice between these methods depends on the specific requirements of part design, industry standards, and production efficiency.

Future Trends in Assisted Injection Molding Technologies

Future trends in assisted injection molding technologies emphasize enhanced precision and sustainability through the integration of gas-assisted and water-assisted molding methods. Advances in gas-assisted molding focus on reducing cycle times and improving part quality by optimizing nitrogen gas injection parameters, while water-assisted molding is gaining traction for its environmental benefits and superior cooling efficiency using pressurized water channels. Emerging hybrid systems combine the strengths of both techniques, leveraging smart sensors and AI-driven process controls to maximize material savings and minimize defects in complex hollow components.

Gas-assisted molding vs water-assisted molding Infographic

libmatt.com

libmatt.com