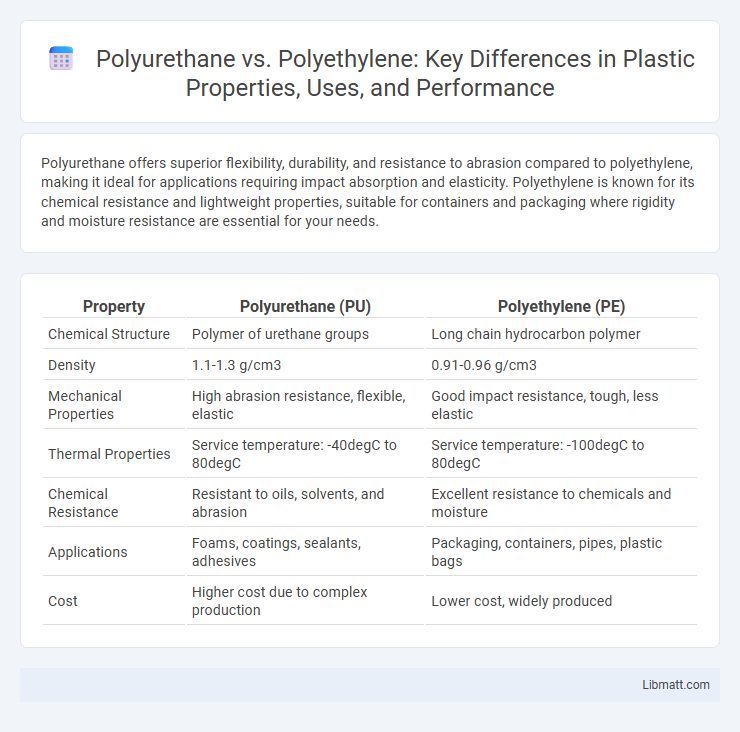

Polyurethane offers superior flexibility, durability, and resistance to abrasion compared to polyethylene, making it ideal for applications requiring impact absorption and elasticity. Polyethylene is known for its chemical resistance and lightweight properties, suitable for containers and packaging where rigidity and moisture resistance are essential for your needs.

Table of Comparison

| Property | Polyurethane (PU) | Polyethylene (PE) |

|---|---|---|

| Chemical Structure | Polymer of urethane groups | Long chain hydrocarbon polymer |

| Density | 1.1-1.3 g/cm3 | 0.91-0.96 g/cm3 |

| Mechanical Properties | High abrasion resistance, flexible, elastic | Good impact resistance, tough, less elastic |

| Thermal Properties | Service temperature: -40degC to 80degC | Service temperature: -100degC to 80degC |

| Chemical Resistance | Resistant to oils, solvents, and abrasion | Excellent resistance to chemicals and moisture |

| Applications | Foams, coatings, sealants, adhesives | Packaging, containers, pipes, plastic bags |

| Cost | Higher cost due to complex production | Lower cost, widely produced |

Introduction to Polyurethane and Polyethylene

Polyurethane is a versatile polymer known for its elasticity, durability, and resistance to abrasion, commonly used in foam cushions, insulation, and coatings. Polyethylene, one of the most widely produced plastics, offers excellent chemical resistance, flexibility, and is lightweight, making it ideal for packaging, containers, and plastic bags. Your choice between polyurethane and polyethylene depends on the specific requirements for flexibility, strength, and environmental exposure in your application.

Chemical Structure and Composition

Polyurethane consists of organic units joined by carbamate (urethane) links, featuring a backbone of alternating soft segments of polyols and hard segments formed by isocyanates, which provides flexibility and durability. Polyethylene is a simple polymer composed of long chains of ethylene monomers, consisting mainly of carbon and hydrogen atoms, creating a non-polar, crystalline structure that offers excellent chemical resistance. Understanding the distinct chemical structures and compositions of polyurethane and polyethylene helps you select the right material based on your specific application and performance requirements.

Physical Properties Comparison

Polyurethane offers superior elasticity, abrasion resistance, and tensile strength compared to polyethylene, which is known for its chemical resistance and lower density. Polyethylene typically exhibits higher impact resistance and flexibility at low temperatures, making it suitable for varied environmental conditions. Understanding these physical properties helps you choose the right material based on durability, resistance, and application requirements.

Durability and Longevity

Polyurethane offers superior durability and longevity compared to polyethylene, thanks to its resistance to abrasion, impact, and environmental factors such as UV exposure and chemicals. Polyethylene, while more affordable and flexible, tends to degrade faster under prolonged exposure to oxidative and weathering conditions. Choosing polyurethane ensures your products maintain structural integrity and performance over an extended period, especially in demanding applications.

Flexibility and Versatility

Polyurethane offers superior flexibility and durability, making it ideal for applications requiring elasticity and impact resistance. Polyethylene, while less flexible, provides excellent chemical resistance and versatility for packaging, containers, and insulation. Your choice depends on whether flexibility or chemical resilience is the priority for your specific project.

Applications in Different Industries

Polyurethane is widely used in automotive manufacturing for cushioning, insulation, and seals due to its flexibility and durability, while polyethylene excels in packaging, containers, and piping due to its chemical resistance and low cost. In construction, polyurethane provides thermal insulation and soundproofing, whereas polyethylene serves as a vapor barrier and moisture-resistant lining. The medical industry favors polyurethane for flexible tubing and wound dressings, whereas polyethylene is common in disposable syringes and prosthetics owing to its biocompatibility.

Environmental Impact and Sustainability

Polyurethane often has a higher environmental impact due to its reliance on non-renewable petrochemicals and challenges in recycling, while polyethylene, especially in its high-density form, offers better recyclability and lower carbon emissions during production. Biodegradability is limited in both materials, but advancements in bio-based polyethylene enhance sustainability prospects. You can reduce your environmental footprint by choosing recycled polyethylene products or seeking polyurethane alternatives with eco-friendly formulations.

Cost and Availability

Polyethylene is generally more cost-effective and widely available due to its extensive use in packaging, containers, and plastic bags. Polyurethane, while more expensive, offers enhanced durability and flexibility, making it common in insulation, coatings, and foam applications. The production scale and raw material costs contribute to polyethylene's lower price and higher accessibility compared to polyurethane.

Maintenance and Care Requirements

Polyurethane requires regular cleaning with mild soap and water to prevent dirt buildup and occasional application of protective sprays to maintain its flexibility and appearance. Polyethylene is low-maintenance, resistant to most chemicals and moisture, and typically only needs simple cleaning with water and mild detergent to keep it in good condition. Both materials benefit from avoiding prolonged exposure to extreme UV light to minimize degradation and extend lifespan.

Conclusion: Choosing the Right Material

Polyurethane offers superior flexibility, abrasion resistance, and durability, making it ideal for applications requiring cushioning or impact absorption. Polyethylene provides excellent chemical resistance, low moisture absorption, and affordability, suited for packaging and containers. Assess your specific project needs to determine whether polyurethane's resilience or polyethylene's cost-effectiveness and chemical stability best align with your goals.

Polyurethane vs Polyethylene Infographic

libmatt.com

libmatt.com