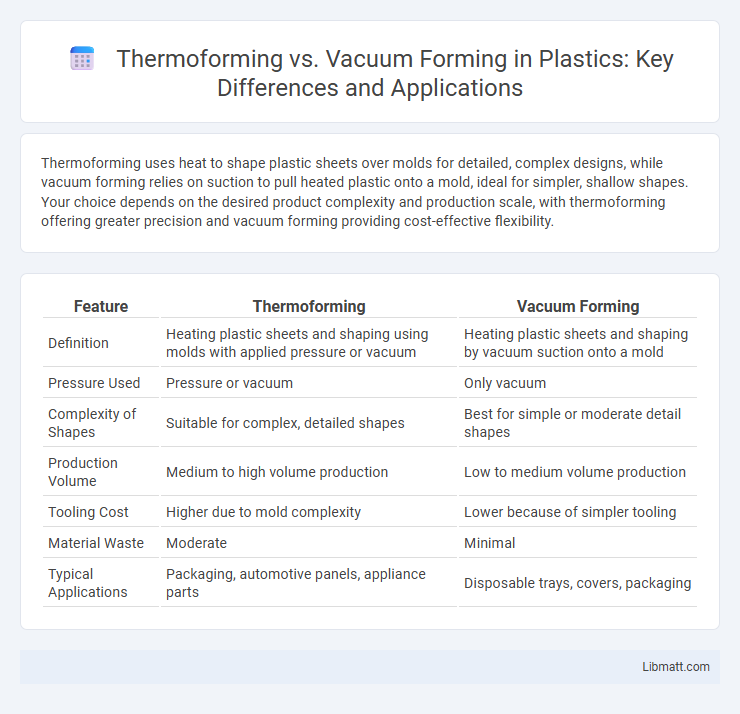

Thermoforming uses heat to shape plastic sheets over molds for detailed, complex designs, while vacuum forming relies on suction to pull heated plastic onto a mold, ideal for simpler, shallow shapes. Your choice depends on the desired product complexity and production scale, with thermoforming offering greater precision and vacuum forming providing cost-effective flexibility.

Table of Comparison

| Feature | Thermoforming | Vacuum Forming |

|---|---|---|

| Definition | Heating plastic sheets and shaping using molds with applied pressure or vacuum | Heating plastic sheets and shaping by vacuum suction onto a mold |

| Pressure Used | Pressure or vacuum | Only vacuum |

| Complexity of Shapes | Suitable for complex, detailed shapes | Best for simple or moderate detail shapes |

| Production Volume | Medium to high volume production | Low to medium volume production |

| Tooling Cost | Higher due to mold complexity | Lower because of simpler tooling |

| Material Waste | Moderate | Minimal |

| Typical Applications | Packaging, automotive panels, appliance parts | Disposable trays, covers, packaging |

Introduction to Thermoforming and Vacuum Forming

Thermoforming and vacuum forming are key plastic shaping techniques widely used in manufacturing and packaging industries. Thermoforming involves heating a plastic sheet until it's pliable, then shaping it using molds, while vacuum forming specifically uses a vacuum to pull the heated sheet onto a mold to achieve detailed contours. Understanding these processes helps optimize material selection and tooling for your production needs, improving efficiency and product quality.

Understanding the Thermoforming Process

Thermoforming involves heating a plastic sheet until it becomes pliable and then shaping it using a mold under pressure or vacuum, allowing for complex and detailed designs. Vacuum forming is a subset of thermoforming where the heated plastic sheet is pulled tightly over a mold by vacuum pressure, ideal for creating lightweight, cost-effective parts with moderate detail. Your choice between these processes depends on the desired product complexity, production volume, and material properties.

How Vacuum Forming Works

Vacuum forming involves heating a plastic sheet until it becomes pliable, then stretching it over a mold while a vacuum pulls the material tightly against the surface to create precise shapes. This method is ideal for producing large, thin-walled parts quickly and cost-effectively, such as packaging trays or automotive panels. Understanding how vacuum forming works helps you choose the right technique for detailed, lightweight product designs.

Key Differences Between Thermoforming and Vacuum Forming

Thermoforming involves heating a plastic sheet until pliable, then shaping it using molds through methods such as vacuum, pressure, or mechanical force, while vacuum forming specifically uses vacuum pressure to pull the heated plastic sheet onto a mold. The key differences lie in the forming techniques and the complexity of shapes achievable; thermoforming offers more versatility and can produce more detailed and multi-part designs compared to vacuum forming's simpler mold shapes. Understanding these distinctions helps you select the appropriate process for your project's precision and budget requirements.

Materials Used in Thermoforming vs Vacuum Forming

Thermoforming utilizes a wide array of thermoplastic materials including ABS, polycarbonate, and polystyrene, offering versatility for both rigid and flexible applications. Vacuum forming, a subset of thermoforming, primarily employs thinner sheet plastics such as high-impact polystyrene (HIPS), acrylic, and PVC, optimized for lightweight and detailed shapes. Material selection in vacuum forming emphasizes ease of mold conformity and cost-efficiency, while thermoforming supports a broader spectrum of thicknesses and mechanical properties.

Advantages of Thermoforming

Thermoforming offers greater design flexibility and can accommodate complex shapes and larger parts compared to vacuum forming. It allows for precise control over thickness and material distribution, ensuring consistent product quality. Your production process benefits from faster cycle times and lower tooling costs, making thermoforming ideal for both prototyping and mass production.

Benefits of Vacuum Forming

Vacuum forming offers precise molding capabilities that create detailed and consistent shapes ideal for prototyping and low-volume production. This process reduces material waste by using thinner sheets of plastic, leading to cost-effective manufacturing and faster turnaround times. Its versatility extends to a wide range of thermoplastics, making it suitable for diverse applications such as packaging, automotive parts, and medical device components.

Typical Applications for Each Process

Thermoforming is commonly used for producing large, rigid parts such as automotive panels, appliance housings, and packaging trays due to its ability to handle thick plastic sheets and complex shapes. Vacuum forming excels in creating lightweight, detailed items like custom packaging, signage, and prototype models by heating thinner plastic sheets and using vacuum pressure to shape them efficiently. You can choose vacuum forming for cost-effective, quick production of small to medium batch runs, while thermoforming suits high-volume manufacturing of durable components.

Cost Comparison: Thermoforming vs Vacuum Forming

Thermoforming generally incurs higher initial tooling costs due to the complexity of molds, whereas vacuum forming offers a more cost-effective solution with simpler mold requirements, making it ideal for low to medium production volumes. The material and operational expenses in vacuum forming are typically lower, leading to reduced overall manufacturing costs compared to thermoforming. For large-scale production, thermoforming's efficiency and precision can justify higher upfront investments with better long-term cost performance.

Choosing the Right Forming Method for Your Project

Thermoforming and vacuum forming differ in complexity and application, with thermoforming suitable for large-scale production and thicker materials, while vacuum forming excels in creating detailed shapes with thinner plastics. Your choice depends on project requirements such as material thickness, design intricacy, and production volume. Opting for thermoforming ensures durability and structural integrity, whereas vacuum forming offers cost-effective solutions for simpler designs.

Thermoforming vs vacuum forming Infographic

libmatt.com

libmatt.com