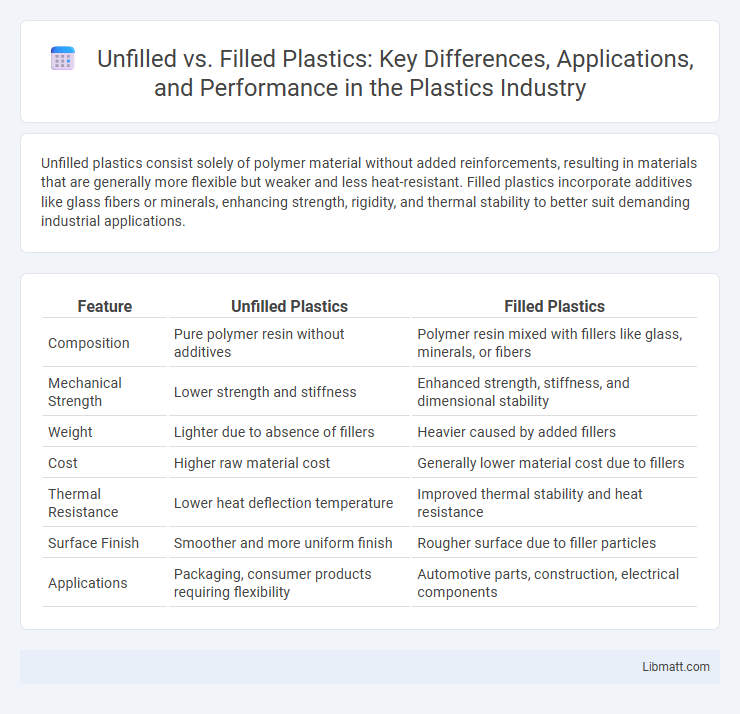

Unfilled plastics consist solely of polymer material without added reinforcements, resulting in materials that are generally more flexible but weaker and less heat-resistant. Filled plastics incorporate additives like glass fibers or minerals, enhancing strength, rigidity, and thermal stability to better suit demanding industrial applications.

Table of Comparison

| Feature | Unfilled Plastics | Filled Plastics |

|---|---|---|

| Composition | Pure polymer resin without additives | Polymer resin mixed with fillers like glass, minerals, or fibers |

| Mechanical Strength | Lower strength and stiffness | Enhanced strength, stiffness, and dimensional stability |

| Weight | Lighter due to absence of fillers | Heavier caused by added fillers |

| Cost | Higher raw material cost | Generally lower material cost due to fillers |

| Thermal Resistance | Lower heat deflection temperature | Improved thermal stability and heat resistance |

| Surface Finish | Smoother and more uniform finish | Rougher surface due to filler particles |

| Applications | Packaging, consumer products requiring flexibility | Automotive parts, construction, electrical components |

Introduction to Unfilled and Filled Plastics

Unfilled plastics consist primarily of polymer resins without additional reinforcing materials, offering flexibility, low density, and ease of processing. Filled plastics incorporate additives such as glass fibers, calcium carbonate, or carbon black to enhance mechanical strength, thermal stability, and dimensional accuracy. These modifications influence the performance characteristics and application scope of the resulting composite materials.

Definition and Composition of Unfilled Plastics

Unfilled plastics are polymer materials composed solely of the base polymer resin without any added reinforcing fillers or additives, resulting in a pure and homogenous structure. Common examples include polyethylene (PE), polypropylene (PP), and polystyrene (PS), which exhibit inherent flexibility and lower mechanical strength compared to filled counterparts. Their composition typically features long hydrocarbon chains and lacks particulate matter such as glass fibers, minerals, or carbon black, making them easier to mold but less stiff or durable.

Definition and Composition of Filled Plastics

Filled plastics consist of a polymer matrix combined with additives such as glass fibers, minerals, or carbon fibers to enhance mechanical, thermal, and electrical properties. Unfilled plastics are pure polymers without any reinforcing fillers, offering greater flexibility, but lower strength and heat resistance compared to their filled counterparts. Your choice between unfilled and filled plastics depends on the specific performance requirements and application environment.

Common Types of Fillers Used in Plastics

Common types of fillers used in plastics include calcium carbonate, talc, and glass fibers, which enhance mechanical properties and reduce material costs. Unfilled plastics offer higher flexibility and clarity, while filled plastics exhibit improved strength, rigidity, and heat resistance due to the added fillers. Your choice between unfilled and filled plastics depends on the specific application requirements and desired performance characteristics.

Mechanical Properties: Unfilled vs Filled Plastics

Unfilled plastics typically exhibit lower tensile strength and stiffness due to their homogeneous polymer matrix, while filled plastics incorporate additives such as glass fibers or mineral fillers that significantly enhance mechanical properties like rigidity, impact resistance, and dimensional stability. The presence of fillers increases the modulus of elasticity and reduces creep, making filled plastics ideal for applications requiring improved load-bearing capabilities and durability. However, filled plastics may experience reduced elongation at break and lower impact toughness compared to unfilled counterparts, necessitating a balance based on specific engineering requirements.

Processing and Manufacturing Differences

Unfilled plastics are typically easier to process due to their lower viscosity and improved flow characteristics, allowing for faster molding cycle times and simpler equipment requirements. Filled plastics contain reinforcing materials such as glass fibers or minerals, which enhance mechanical properties but often necessitate higher processing temperatures and specialized machinery to handle increased abrasiveness and viscosity. Your choice between unfilled and filled plastics will impact mold design, processing parameters, and ultimately production efficiency based on the specific application requirements.

Cost Comparison: Unfilled vs Filled Options

Unfilled plastics generally have lower material costs compared to filled plastics due to the absence of reinforcing agents such as glass fibers or mineral fillers. Filled plastics incur higher expenses not only from the cost of additives but also from increased processing requirements and tool wear. However, the enhanced mechanical properties and improved durability of filled plastics often justify their higher initial cost in performance-critical applications.

Application Areas for Unfilled Plastics

Unfilled plastics are widely used in applications requiring high flexibility, clarity, and ease of processing, such as packaging films, medical devices, and consumer goods. Their low density and excellent chemical resistance make them ideal for lightweight automotive components and electrical insulation. Your choice of unfilled plastics supports industries that prioritize versatility and cost-effective manufacturing without compromising material performance.

Application Areas for Filled Plastics

Filled plastics are extensively used in automotive components, construction materials, and electrical housings due to their enhanced mechanical strength and thermal stability. Mineral fillers and glass fibers improve durability and reduce material costs, making them ideal for high-performance parts in appliances and industrial equipment. Your choice of filled plastics can optimize performance in demanding environments, providing superior structural integrity and resistance to wear.

Choosing Between Unfilled and Filled Plastics: Key Considerations

Choosing between unfilled and filled plastics depends on the specific application requirements such as mechanical strength, thermal stability, and cost efficiency. Filled plastics, enhanced with additives like glass fibers or mineral fillers, offer improved rigidity, heat resistance, and wear properties compared to unfilled plastics, which provide greater flexibility and ease of processing. Evaluating factors such as end-use performance, environmental exposure, and manufacturing constraints is essential for selecting the appropriate plastic type to optimize durability and functionality.

Unfilled vs Filled Plastics Infographic

libmatt.com

libmatt.com