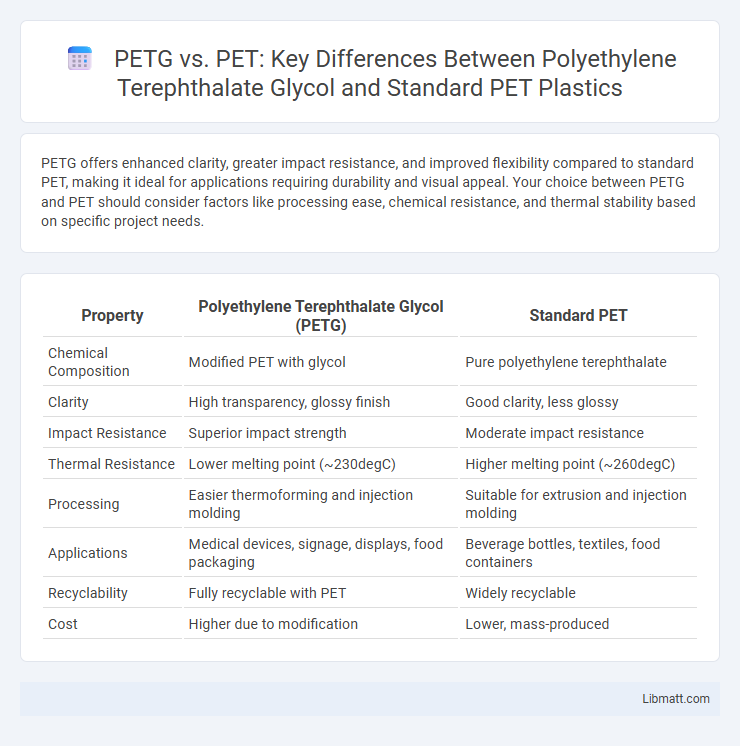

PETG offers enhanced clarity, greater impact resistance, and improved flexibility compared to standard PET, making it ideal for applications requiring durability and visual appeal. Your choice between PETG and PET should consider factors like processing ease, chemical resistance, and thermal stability based on specific project needs.

Table of Comparison

| Property | Polyethylene Terephthalate Glycol (PETG) | Standard PET |

|---|---|---|

| Chemical Composition | Modified PET with glycol | Pure polyethylene terephthalate |

| Clarity | High transparency, glossy finish | Good clarity, less glossy |

| Impact Resistance | Superior impact strength | Moderate impact resistance |

| Thermal Resistance | Lower melting point (~230degC) | Higher melting point (~260degC) |

| Processing | Easier thermoforming and injection molding | Suitable for extrusion and injection molding |

| Applications | Medical devices, signage, displays, food packaging | Beverage bottles, textiles, food containers |

| Recyclability | Fully recyclable with PET | Widely recyclable |

| Cost | Higher due to modification | Lower, mass-produced |

Introduction to PETG and Standard PET

Polyethylene Terephthalate Glycol (PETG) is a thermoplastic polyester known for its enhanced chemical resistance, durability, and ease of thermoforming compared to Standard Polyethylene Terephthalate (PET). Standard PET exhibits high strength, clarity, and excellent gas barrier properties, making it widely used in beverage containers and food packaging. PETG's improved impact resistance and lower melting point make it preferable for applications requiring enhanced flexibility and faster production cycles.

Chemical Structure Differences

Polyethylene Terephthalate Glycol (PETG) differs from standard PET primarily in its chemical structure, where the addition of glycol modifies the polymer chain, reducing crystallinity and enhancing clarity and impact resistance. This structural variation results in a more amorphous material, allowing PETG to maintain transparency and flexibility, unlike the more rigid and opaque standard PET. Understanding these chemical differences helps you choose the right material for applications requiring durability and aesthetic appeal.

Mechanical Properties Comparison

Polyethylene Terephthalate Glycol (PETG) exhibits enhanced impact resistance and higher flexibility compared to standard PET, making it ideal for applications requiring durability and toughness. PETG also offers improved elongation at break and better resistance to cracking under stress, whereas PET provides higher stiffness and strength suitable for rigid packaging. The mechanical property differences between PETG and PET are crucial for selecting the appropriate polymer based on specific performance requirements in manufacturing.

Transparency and Optical Clarity

Polyethylene Terephthalate Glycol (PETG) exhibits superior transparency and optical clarity compared to standard PET due to its enhanced amorphous structure, which minimizes light scattering. PETG's lower crystallinity results in a clearer and more brilliant appearance, making it ideal for applications requiring high visual aesthetics such as food packaging and medical devices. Standard PET, while durable, tends to have slightly reduced clarity because of its higher crystallinity, leading to a more opaque look.

Thermal Resistance and Stability

Polyethylene Terephthalate Glycol (PETG) exhibits superior thermal resistance and enhanced stability compared to standard PET, maintaining structural integrity at higher temperatures up to 80-85degC, whereas standard PET typically softens around 70-75degC. PETG's modified glycol component prevents crystallization, providing greater clarity and dimensional stability under thermal stress, making it ideal for applications requiring durability under heat. Your choice of PETG ensures better performance in environments with fluctuating temperatures and increased resistance to thermal deformation.

Ease of Processing and Fabrication

Polyethylene Terephthalate Glycol (PETG) offers superior ease of processing and fabrication compared to standard PET due to its lower melting point and increased flexibility, which reduces the risk of cracking during thermoforming and 3D printing. PETG's enhanced chemical resistance and clarity make it ideal for applications requiring rapid prototyping or intricate designs, enabling smoother post-processing and better layer adhesion. Your manufacturing workflow benefits from PETG's forgiving processing window, allowing faster production cycles and less equipment wear.

Applications in Various Industries

Polyethylene Terephthalate Glycol (PETG) offers enhanced durability and chemical resistance compared to standard PET, making it ideal for packaging in the food and beverage industry, as well as medical devices requiring sterilization. Its superior clarity and impact resistance support applications in signage, displays, and consumer goods, while standard PET remains cost-effective for lightweight containers and textile fibers. Your choice between PETG and PET depends on the specific performance requirements and environmental factors of your industry application.

Environmental Impact and Recyclability

Polyethylene Terephthalate Glycol (PETG) offers enhanced clarity and flexibility compared to standard PET but presents challenges in recycling due to its modified glycol content, which can contaminate PET recycling streams and reduce overall recyclability rates. Standard PET is widely accepted in recycling programs and boasts a well-established infrastructure, making it more environmentally favorable in terms of circularity and resource recovery. Your choice between PETG and PET should consider the end-of-life management and local recycling capabilities to minimize environmental impact effectively.

Cost and Market Availability

Polyethylene Terephthalate Glycol (PETG) typically costs more than standard PET due to its enhanced clarity, impact resistance, and ease of thermoforming, making it a preferred choice for premium applications. Standard PET benefits from widespread market availability and lower production costs, resulting in its dominance in packaging, especially for bottles and containers. Your selection between PETG and PET should consider budget constraints and the availability of material suited for your specific manufacturing needs.

Choosing Between PETG and Standard PET

Choosing between Polyethylene Terephthalate Glycol (PETG) and standard PET depends on your project's specific requirements. PETG offers superior impact resistance, clarity, and ease of thermoforming, making it ideal for applications needing durability and a glossy finish. Standard PET provides excellent chemical resistance and rigidity, often preferred for food and beverage packaging due to its recyclability and cost-effectiveness.

Polyethylene Terephthalate Glycol (PETG) vs Standard PET Infographic

libmatt.com

libmatt.com