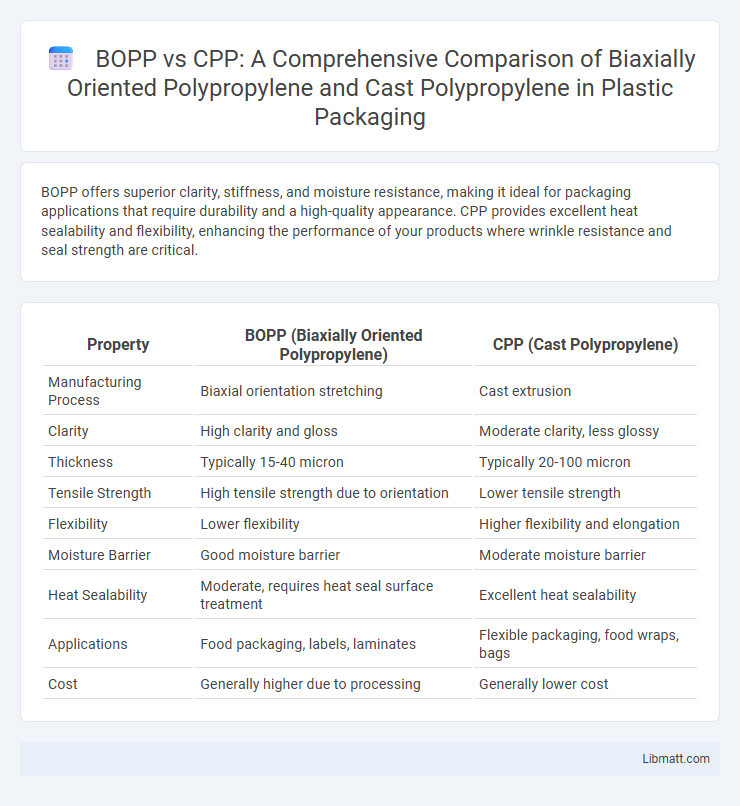

BOPP offers superior clarity, stiffness, and moisture resistance, making it ideal for packaging applications that require durability and a high-quality appearance. CPP provides excellent heat sealability and flexibility, enhancing the performance of your products where wrinkle resistance and seal strength are critical.

Table of Comparison

| Property | BOPP (Biaxially Oriented Polypropylene) | CPP (Cast Polypropylene) |

|---|---|---|

| Manufacturing Process | Biaxial orientation stretching | Cast extrusion |

| Clarity | High clarity and gloss | Moderate clarity, less glossy |

| Thickness | Typically 15-40 micron | Typically 20-100 micron |

| Tensile Strength | High tensile strength due to orientation | Lower tensile strength |

| Flexibility | Lower flexibility | Higher flexibility and elongation |

| Moisture Barrier | Good moisture barrier | Moderate moisture barrier |

| Heat Sealability | Moderate, requires heat seal surface treatment | Excellent heat sealability |

| Applications | Food packaging, labels, laminates | Flexible packaging, food wraps, bags |

| Cost | Generally higher due to processing | Generally lower cost |

Introduction to BOPP and CPP Films

BOPP (Biaxially Oriented Polypropylene) films are polypropylene films stretched in both machine and transverse directions, resulting in enhanced strength, clarity, and barrier properties. CPP (Cast Polypropylene) films are produced by casting molten polypropylene onto a chill roll, creating films with superior clarity, sealability, and flexibility compared to BOPP. Both BOPP and CPP films are widely used in packaging applications, with BOPP preferred for high-tensile strength and CPP for excellent sealing performance.

Manufacturing Processes: BOPP vs CPP

BOPP (Biaxially Oriented Polypropylene) is produced through a simultaneous stretching process in both machine and transverse directions, enhancing its tensile strength, clarity, and barrier properties. CPP (Cast Polypropylene) is manufactured by melting and casting molten polymer onto a chill roll, resulting in a film with higher thickness uniformity and excellent sealability. The biaxial orientation in BOPP contributes to its stiffness and optical clarity, while the casting process in CPP allows for greater flexibility and better heat resistance.

Physical and Mechanical Properties Comparison

BOPP (Biaxially Oriented Polypropylene) offers superior tensile strength and stiffness due to its molecular orientation in both machine and transverse directions, enhancing its mechanical durability compared to CPP (Cast Polypropylene), which is softer and more flexible with lower tensile strength. BOPP exhibits higher clarity and better moisture barrier properties, making it ideal for packaging applications requiring transparency and protection, while CPP provides excellent heat sealability and puncture resistance due to its cast film structure. Your choice between these films depends on the balance needed between mechanical strength and flexibility for specific packaging or industrial uses.

Barrier Properties: Moisture, Oxygen, and Aroma

BOPP (Biaxially Oriented Polypropylene) offers superior moisture barrier properties compared to CPP (Cast Polypropylene), making it ideal for products requiring extended shelf life. CPP provides better oxygen barrier performance, which helps in preserving the freshness and preventing oxidation of sensitive goods. In terms of aroma retention, BOPP films are generally more effective in preventing the loss of volatile compounds, ensuring product integrity during storage.

Optical Clarity and Printability

Biaxially Oriented Polypropylene (BOPP) offers superior optical clarity compared to Cast Polypropylene (CPP), making it ideal for high-quality packaging that demands excellent gloss and transparency. BOPP's enhanced molecular orientation results in a smoother surface, which significantly improves printability and color vibrancy in flexographic and rotogravure printing processes. CPP, while more flexible and heat-resistant, generally exhibits lower clarity and print definition, making it less suitable for premium visual applications.

Typical Applications in Packaging Industry

BOPP (Biaxially Oriented Polypropylene) is widely used in packaging for its high clarity, excellent moisture resistance, and superior tensile strength, making it ideal for food packaging, labels, and snack wrappers. CPP (Cast Polypropylene) offers enhanced sealability, flexibility, and impact resistance, often utilized in flow packs, twist wraps, and lamination films. Both materials serve crucial roles in the packaging industry, with BOPP favored for rigid applications and CPP preferred for flexible films requiring strong seals.

Cost Analysis: BOPP vs CPP

BOPP films generally exhibit a higher cost due to their complex biaxial orientation process, which enhances mechanical strength and clarity. CPP films incur lower production costs because of the simpler cast extrusion method, making them more economical for applications requiring flexibility and heat-sealability. Cost efficiency between BOPP and CPP depends on specific packaging requirements, with BOPP favored for premium quality and CPP preferred for budget-sensitive uses.

Environmental Impact and Recyclability

Biaxially Oriented Polypropylene (BOPP) generally offers better environmental performance compared to Cast Polypropylene (CPP) due to its higher recyclability and lower carbon footprint during production. BOPP films are widely accepted in recycling facilities, contributing to reduced plastic waste and enhanced circular economy practices. CPP, while flexible and suitable for various applications, presents more challenges in recycling due to its multilayer use and lower compatibility with standard recycling streams.

Choosing the Right Film for Your Product

BOPP (Biaxially Oriented Polypropylene) offers superior tensile strength, clarity, and moisture resistance, making it ideal for packaging snacks, confectionery, and labels requiring high gloss and durability. CPP (Cast Polypropylene) provides better heat sealability, flexibility, and tear resistance suitable for applications like food packaging, flow wraps, and lamination where softer films are needed. Selecting between BOPP and CPP depends on your product's specific requirements for barrier properties, sealing performance, and aesthetic appeal.

Future Trends in Polypropylene Films

Future trends in polypropylene films emphasize enhanced barrier properties and sustainability, driving innovation in BOPP and CPP materials. Advanced coatings and nanocomposite integrations improve BOPP's mechanical strength and clarity, making it ideal for high-performance packaging. CPP films are evolving with biodegradable formulations and improved sealability, aligning with growing eco-friendly packaging demands and regulatory pressures.

BOPP vs CPP (Biaxially Oriented Polypropylene vs Cast Polypropylene) Infographic

libmatt.com

libmatt.com