Post-consumer recycled plastic is derived from materials discarded by end-users after product use, while post-industrial recycled plastic comes from manufacturing waste before products reach consumers. Your choice between these types depends on factors like sustainability goals, material quality, and availability for your production needs.

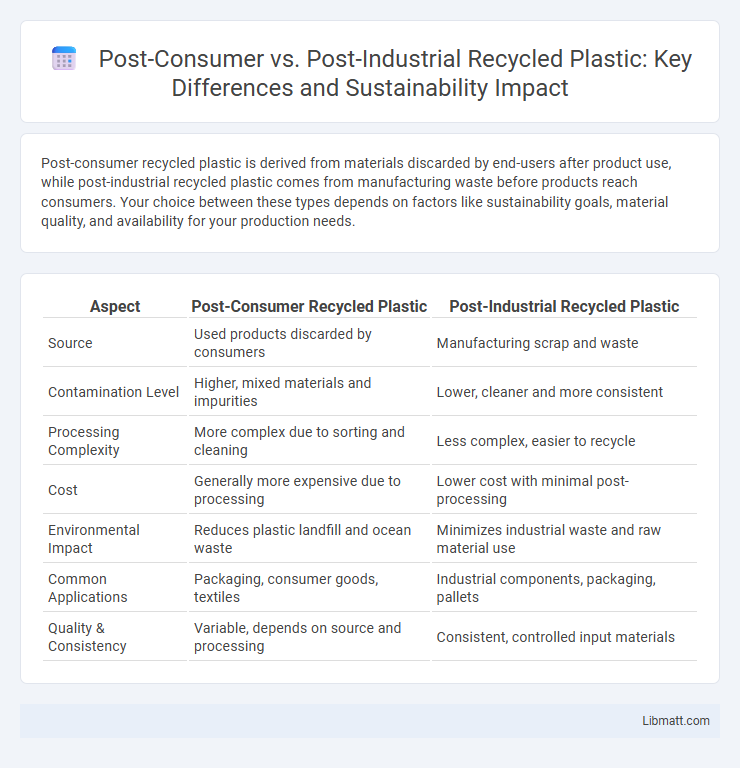

Table of Comparison

| Aspect | Post-Consumer Recycled Plastic | Post-Industrial Recycled Plastic |

|---|---|---|

| Source | Used products discarded by consumers | Manufacturing scrap and waste |

| Contamination Level | Higher, mixed materials and impurities | Lower, cleaner and more consistent |

| Processing Complexity | More complex due to sorting and cleaning | Less complex, easier to recycle |

| Cost | Generally more expensive due to processing | Lower cost with minimal post-processing |

| Environmental Impact | Reduces plastic landfill and ocean waste | Minimizes industrial waste and raw material use |

| Common Applications | Packaging, consumer goods, textiles | Industrial components, packaging, pallets |

| Quality & Consistency | Variable, depends on source and processing | Consistent, controlled input materials |

Understanding Post-Consumer vs Post-Industrial Recycled Plastic

Post-consumer recycled plastic comes from materials discarded by consumers after use, such as beverage bottles and packaging, while post-industrial recycled plastic is extracted from manufacturing waste before reaching the consumer. Understanding the distinction helps optimize recycling strategies and improve sustainability efforts in your product lifecycle. Utilizing post-consumer plastic often supports circular economy goals, whereas post-industrial plastic recycling reduces manufacturing waste and resource consumption.

Defining Post-Consumer Recycled (PCR) Plastic

Post-Consumer Recycled (PCR) plastic is material recovered from products that have been used and discarded by consumers, such as plastic bottles, containers, and packaging. This type of recycled plastic undergoes collection, sorting, and processing to create new plastic feedstock, reducing waste sent to landfills and decreasing reliance on virgin plastic production. PCR plastic is a key component in sustainable manufacturing, promoting circular economy principles by reintroducing consumer-generated waste into the supply chain.

What Is Post-Industrial Recycled (PIR) Plastic?

Post-industrial recycled (PIR) plastic refers to material reclaimed from manufacturing waste generated during industrial production processes before consumer use. This plastic is typically clean, uncontaminated, and includes off-cuts, trimmings, or defective products, making it easier to recycle efficiently. PIR plastic differs from post-consumer recycled plastic, which comes from products discarded by consumers after use and often requires more complex sorting and cleaning.

Sources of Post-Consumer and Post-Industrial Plastics

Post-consumer recycled plastic originates from products that have been used and discarded by consumers, such as water bottles, packaging, and household containers collected through municipal recycling programs. Post-industrial recycled plastic comes from manufacturing waste like scrap materials, trimmings, and defective products generated during the production process before reaching consumers. Understanding the distinct sources helps you choose the appropriate recycled plastic type for specific applications, ensuring sustainability and material quality.

Collection and Processing Methods

Post-consumer recycled plastic is collected from consumer-used products through curbside recycling programs and drop-off centers, requiring extensive sorting to remove contaminants before processing. Post-industrial recycled plastic originates from manufacturing waste, collected directly at production sites with minimal contamination, enabling more efficient processing using methods like shredding and pelletizing. Advanced technologies such as infrared sorting and washing systems enhance the quality and purity of both types of recycled plastics, optimizing their reuse in new products.

Environmental Impact Comparison

Post-consumer recycled plastic reduces environmental impact by diverting waste from landfills and oceans, lowering greenhouse gas emissions associated with virgin plastic production. Post-industrial recycled plastic minimizes scrap waste generated during manufacturing processes, promoting resource efficiency but often involving cleaner and less contaminated material streams. Both types contribute to circular economy goals, yet post-consumer recycling generally offers greater benefits in reducing plastic pollution and conserving natural resources on a larger scale.

Quality and Performance Differences

Post-consumer recycled plastic typically exhibits more variability in quality and performance due to contamination and mixed waste sources, impacting consistency and durability. In contrast, post-industrial recycled plastic is generally more uniform and maintains higher integrity since it originates from controlled manufacturing scrap with fewer impurities. Your choice between the two should consider the specific application requirements, balancing cost-effectiveness with the desired reliability and appearance.

Applications and Common Uses

Post-consumer recycled plastic is primarily used in manufacturing products like packaging, bottles, and outdoor furniture, offering sustainability benefits in everyday consumer goods. Post-industrial recycled plastic, originating from manufacturing waste, is commonly utilized in applications such as automotive parts, construction materials, and industrial packaging due to its controlled quality and consistency. Understanding these distinctions can help you select the right recycled material for your project's specific performance and environmental requirements.

Market Trends and Industry Adoption

Post-consumer recycled plastic, derived from materials discarded by consumers, is increasingly favored due to growing environmental awareness and stringent sustainability regulations driving market demand. Post-industrial recycled plastic, sourced from manufacturing waste, remains a cost-effective option, though industry adoption is shifting toward post-consumer materials to meet circular economy goals. Your business can capitalize on these market trends by integrating post-consumer recycled plastics, enhancing brand reputation and aligning with evolving industry standards.

Choosing the Right Recycled Plastic for Your Needs

Post-consumer recycled plastic originates from materials discarded by consumers after product use, making it ideal for applications prioritizing environmental impact and recycling credibility. Post-industrial recycled plastic consists of manufacturing scraps and offcuts, offering higher purity and consistent quality suited for controlled production processes. Understanding these differences helps you select recycled plastic that matches your product requirements, balancing sustainability goals with material performance.

Post-consumer vs post-industrial recycled plastic Infographic

libmatt.com

libmatt.com