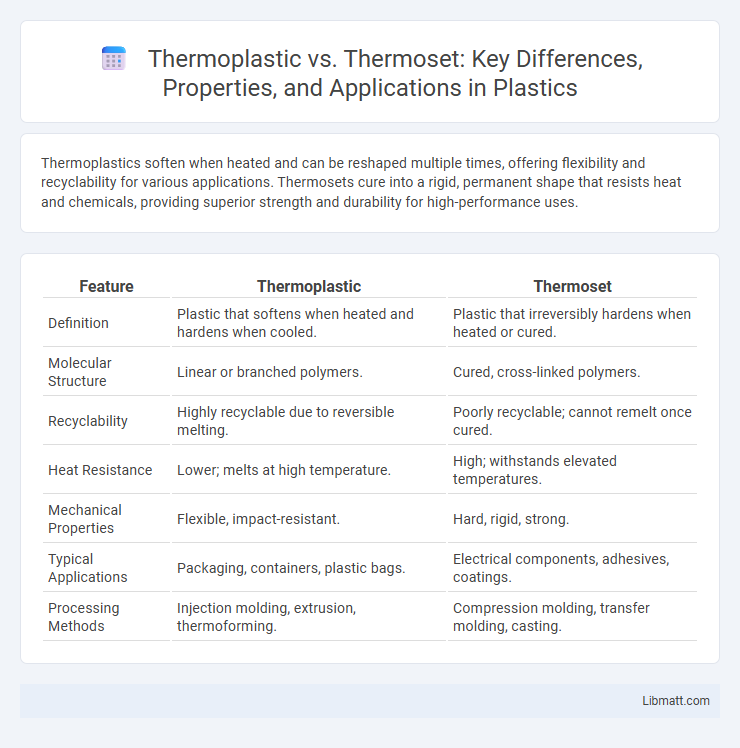

Thermoplastics soften when heated and can be reshaped multiple times, offering flexibility and recyclability for various applications. Thermosets cure into a rigid, permanent shape that resists heat and chemicals, providing superior strength and durability for high-performance uses.

Table of Comparison

| Feature | Thermoplastic | Thermoset |

|---|---|---|

| Definition | Plastic that softens when heated and hardens when cooled. | Plastic that irreversibly hardens when heated or cured. |

| Molecular Structure | Linear or branched polymers. | Cured, cross-linked polymers. |

| Recyclability | Highly recyclable due to reversible melting. | Poorly recyclable; cannot remelt once cured. |

| Heat Resistance | Lower; melts at high temperature. | High; withstands elevated temperatures. |

| Mechanical Properties | Flexible, impact-resistant. | Hard, rigid, strong. |

| Typical Applications | Packaging, containers, plastic bags. | Electrical components, adhesives, coatings. |

| Processing Methods | Injection molding, extrusion, thermoforming. | Compression molding, transfer molding, casting. |

Introduction to Thermoplastics and Thermosets

Thermoplastics are polymers that soften when heated and solidify upon cooling, allowing them to be reshaped multiple times without significant chemical change. Thermosets, in contrast, undergo a chemical curing process that creates a rigid, infusible structure, making them resistant to melting or reshaping after curing. Understanding these fundamental differences helps optimize your material selection for applications requiring either flexibility and recyclability or high heat resistance and structural stability.

Key Differences Between Thermoplastics and Thermosets

Thermoplastics are polymers that soften when heated and harden upon cooling, allowing for repeated reshaping without chemical change, while thermosets undergo a one-time curing process that creates a rigid, permanent structure resistant to heat and deformation. Thermoplastics typically exhibit recyclability and flexibility, making them ideal for applications requiring reshaping and remolding, whereas thermosets offer superior mechanical strength, thermal stability, and chemical resistance suited for high-performance engineering components. Key differences include their molecular structure--linear or branched polymers in thermoplastics versus cross-linked networks in thermosets--and their contrasting thermal behaviors and recyclability.

Chemical Structure and Composition

Thermoplastics consist of linear or branched polymer chains that soften when heated due to weak intermolecular forces, allowing them to be reshaped multiple times. Thermosets feature heavily cross-linked polymer networks formed by strong covalent bonds, which create a rigid structure that remains solid and cannot be remelted after curing. Understanding the distinct chemical structures helps you choose the right material for applications requiring flexibility or permanent durability.

Manufacturing Processes

Thermoplastic manufacturing involves processes such as injection molding, extrusion, and thermoforming, allowing the material to be melted and reshaped multiple times due to its reversible softening property. Thermoset manufacturing typically includes compression molding, transfer molding, and casting, where the material undergoes an irreversible chemical curing process that creates a rigid, heat-resistant structure. Understanding these distinct manufacturing methods is crucial for selecting appropriate materials for applications requiring either reusability or structural durability.

Mechanical and Thermal Properties

Thermoplastics exhibit high impact resistance and flexibility due to their linear polymer chains, making them suitable for applications requiring toughness and recyclability. Thermosets possess superior thermal stability and mechanical strength from their cross-linked network structure, enabling them to withstand higher temperatures and resist deformation under stress. Your choice between thermoplastic and thermoset materials should consider the operational thermal limits and mechanical load requirements of your specific application.

Common Applications and Industry Use

Thermoplastics are widely used in automotive parts, packaging, and consumer goods due to their recyclability and ease of molding, with materials like polyethylene and polypropylene dominating these sectors. Thermosets, including epoxy and phenolic resins, are preferred for high-performance applications in aerospace, electronics, and automotive industries because of their superior heat resistance and structural integrity. The choice between thermoplastic and thermoset depends on the specific industry requirements for durability, flexibility, and thermal stability.

Advantages of Thermoplastics

Thermoplastics offer superior versatility due to their ability to be reheated and reshaped multiple times without degradation, making them ideal for recycling and reducing environmental impact. Their impact resistance and flexibility provide enhanced durability in applications requiring toughness and repeated stress handling. You benefit from cost-effective manufacturing processes like injection molding, enabling rapid production and design adaptability across various industries.

Advantages of Thermosets

Thermoset plastics offer superior heat resistance and structural stability due to their cross-linked polymer chains, making them ideal for high-temperature applications and mechanical strength requirements. Their enhanced chemical resistance and dimensional stability ensure long-lasting durability in harsh environments. You benefit from reliable performance in electrical insulation, automotive components, and aerospace parts where durability and resistance to deformation are critical.

Environmental Impact and Recyclability

Thermoplastics offer superior environmental benefits due to their ability to be repeatedly melted and reshaped, which greatly facilitates recycling and reduces landfill waste. Thermosets, once cured, form irreversible chemical bonds that prevent remelting, making them difficult to recycle and often leading to higher environmental persistence. Advances in thermoplastic recycling technologies and the development of bio-based alternatives further enhance their sustainability compared to traditional thermoset materials.

Choosing the Right Material: Thermoplastic or Thermoset

Choosing the right material involves understanding that thermoplastics offer recyclability, flexibility, and ease of molding, making them ideal for applications requiring frequent reshaping or lightweight components. Thermosets provide superior heat resistance, mechanical strength, and chemical stability, suited for aerospace, automotive, and electrical insulation where durability under stress is critical. Assess factors like operating temperature, mechanical load, and environmental exposure to determine whether the reusability of thermoplastics or the robustness of thermosets aligns better with project requirements.

Thermoplastic vs Thermoset Infographic

libmatt.com

libmatt.com