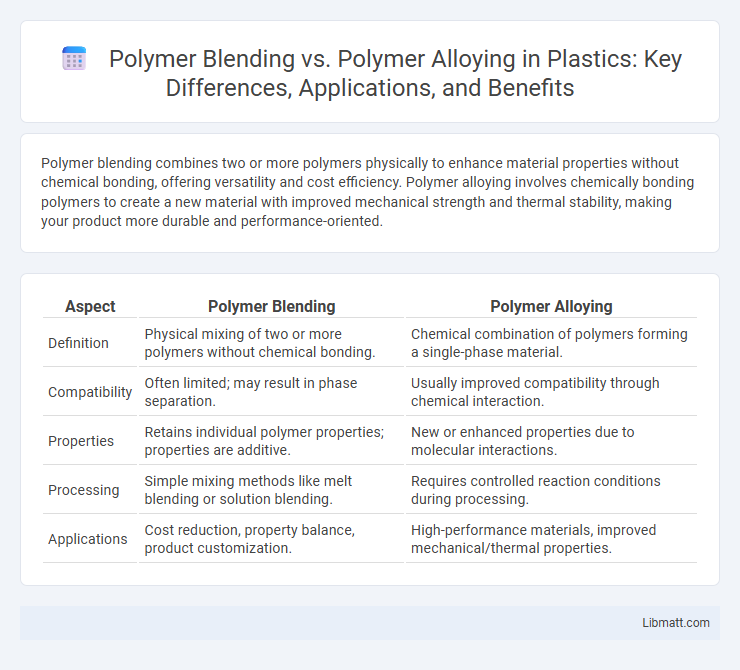

Polymer blending combines two or more polymers physically to enhance material properties without chemical bonding, offering versatility and cost efficiency. Polymer alloying involves chemically bonding polymers to create a new material with improved mechanical strength and thermal stability, making your product more durable and performance-oriented.

Table of Comparison

| Aspect | Polymer Blending | Polymer Alloying |

|---|---|---|

| Definition | Physical mixing of two or more polymers without chemical bonding. | Chemical combination of polymers forming a single-phase material. |

| Compatibility | Often limited; may result in phase separation. | Usually improved compatibility through chemical interaction. |

| Properties | Retains individual polymer properties; properties are additive. | New or enhanced properties due to molecular interactions. |

| Processing | Simple mixing methods like melt blending or solution blending. | Requires controlled reaction conditions during processing. |

| Applications | Cost reduction, property balance, product customization. | High-performance materials, improved mechanical/thermal properties. |

Introduction to Polymer Modification Techniques

Polymer blending and polymer alloying are key polymer modification techniques used to enhance material properties by combining different polymers. Polymer blending involves physically mixing polymers to create a material with combined characteristics but without chemical bonding, while polymer alloying typically includes reactive processes that modify molecular structures for improved compatibility and performance. Understanding these techniques allows you to tailor polymer properties for specific applications, optimizing strength, flexibility, and thermal resistance.

Defining Polymer Blending

Polymer blending refers to the physical mixing of two or more polymers without chemical bonding, creating a material that combines the properties of each component but retains their individual phase structures. This process is typically straightforward and cost-effective, allowing manufacturers to enhance performance characteristics such as impact resistance, flexibility, or thermal stability. Unlike polymer alloying, which involves chemical reactions to form a new copolymer with a homogeneous molecular structure, polymer blending results in a heterogeneous material with distinct polymer phases.

Understanding Polymer Alloying

Polymer alloying involves combining two or more polymers at the molecular level to create a single homogeneous material with enhanced mechanical, thermal, or chemical properties. Unlike polymer blending, which may result in phase-separated materials with distinct domains, polymer alloys exhibit improved compatibility and synergistic effects, leading to superior performance in applications such as automotive parts and packaging. Understanding polymer alloying allows you to tailor material properties more precisely for specific engineering requirements.

Key Differences Between Blending and Alloying

Polymer blending involves physically mixing two or more polymers to create a material with combined properties without forming new chemical bonds, while polymer alloying typically refers to chemically combining polymers to produce a homogeneous material with enhanced mechanical and thermal properties. The key differences lie in the interaction level, as blending relies on physical compatibility and phase morphology, whereas alloying results in molecular-level integration through copolymerization or reactive mixing. Your choice between blending and alloying depends on desired material performance, processing conditions, and compatibility requirements.

Chemical and Physical Properties Comparison

Polymer blending combines two or more polymers physically without chemical bonding, often resulting in phase-separated structures that retain individual polymer characteristics, such as distinct melting points and glass transition temperatures. Polymer alloying involves chemical interactions or compatibilization between polymers, leading to improved miscibility, enhanced mechanical strength, and altered thermal properties through intermolecular bonding. The key difference lies in the extent of molecular integration, where alloys typically exhibit superior uniformity in chemical and physical properties compared to blends, enhancing performance in applications requiring consistent material characteristics.

Processing Methods for Polymer Blends and Alloys

Polymer blending typically employs melt blending and solution blending methods, leveraging extrusion and mixing processes to achieve uniform dispersion of components. Polymer alloying often involves reactive extrusion or in situ polymerization, enabling chemical compatibility and enhanced interfacial adhesion between polymers. Understanding these processing methods allows your material design to optimize mechanical properties and performance for specific applications.

Performance and Application Areas

Polymer blending offers improved material properties such as enhanced impact resistance and cost efficiency, making it suitable for packaging, automotive parts, and consumer goods. Polymer alloying achieves superior performance by chemically bonding polymers, resulting in enhanced thermal stability, mechanical strength, and chemical resistance, ideal for high-performance engineering applications like aerospace, electronics, and medical devices. The choice between blending and alloying depends on required property enhancement, processing complexity, and end-use application demands.

Advantages and Disadvantages of Each Approach

Polymer blending offers cost-effective customization and ease of processing, providing improved mechanical properties and flexibility by combining existing polymers without chemical reactions; however, it often suffers from phase separation and limited compatibility, affecting performance consistency. Polymer alloying creates chemically bonded materials with enhanced thermal stability, mechanical strength, and homogeneous properties, but involves complex processing, higher costs, and challenges in controlling reaction conditions. Your choice between these methods depends on balancing processing complexity against desired material performance and application requirements.

Industry Trends in Polymer Blending and Alloying

Industry trends in polymer blending emphasize cost-effective customization by combining polymers to enhance mechanical properties and processing efficiency. Polymer alloying is gaining traction for producing high-performance materials with synergistic characteristics suitable for automotive, aerospace, and electronics sectors. Market growth is driven by innovation in compatibilizers and advanced blending techniques, promoting sustainable and lightweight polymer solutions.

Future Prospects and Challenges in Polymer Material Science

Polymer blending offers a cost-effective approach to enhancing material properties by physically mixing polymers, while polymer alloying achieves more uniform phase integration through chemical compatibilization, promising superior performance in advanced applications. Future prospects in polymer material science include the development of smart, multifunctional materials with tailored mechanical, thermal, and chemical properties for sectors like aerospace, automotive, and biomedical engineering. Your challenge lies in overcoming issues related to phase separation, compatibility, and scalability to harness the full potential of these techniques in next-generation polymer innovations.

Polymer Blending vs Polymer Alloying Infographic

libmatt.com

libmatt.com