The H-Bot design offers a simple mechanical layout with two motors driving a single belt loop, which can limit rigidity and precision compared to the CoreXY system. CoreXY robots provide better structural stability and higher accuracy by using two motors working independently to control coordinated belt paths, making your choice crucial for applications demanding precise motion control.

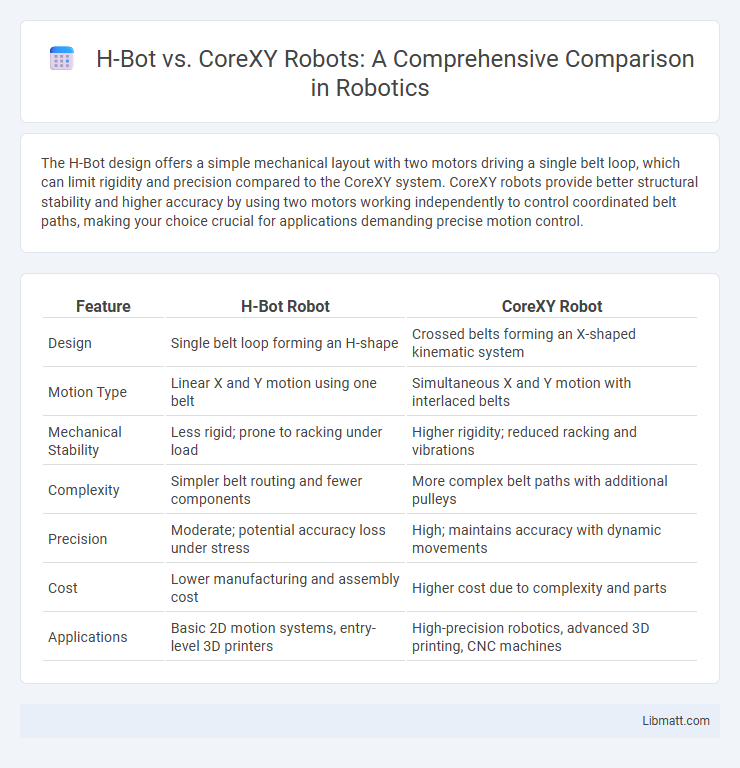

Table of Comparison

| Feature | H-Bot Robot | CoreXY Robot |

|---|---|---|

| Design | Single belt loop forming an H-shape | Crossed belts forming an X-shaped kinematic system |

| Motion Type | Linear X and Y motion using one belt | Simultaneous X and Y motion with interlaced belts |

| Mechanical Stability | Less rigid; prone to racking under load | Higher rigidity; reduced racking and vibrations |

| Complexity | Simpler belt routing and fewer components | More complex belt paths with additional pulleys |

| Precision | Moderate; potential accuracy loss under stress | High; maintains accuracy with dynamic movements |

| Cost | Lower manufacturing and assembly cost | Higher cost due to complexity and parts |

| Applications | Basic 2D motion systems, entry-level 3D printers | High-precision robotics, advanced 3D printing, CNC machines |

Introduction to H-Bot and CoreXY Robots

H-Bot and CoreXY robots are two popular Cartesian motion systems used in 3D printing and CNC applications, each employing a unique belt arrangement for precise X-Y axis movement. The H-Bot utilizes a single continuous belt with two motors positioned on the same axis, offering a simpler mechanical design but with potential torque issues during fast movements. CoreXY incorporates a crossed belt system with motors mounted on fixed frames, providing enhanced rigidity and speed, making your choice crucial depending on the desired balance between simplicity and performance.

Overview of Cartesian Motion Systems

H-Bot and CoreXY are both Cartesian motion systems designed for precision and speed in 3D printing and CNC applications, but they differ significantly in their belt routing and mechanical arrangement. The H-Bot uses a single belt looped in an H shape, which can introduce racking forces due to its asymmetric drive, impacting accuracy under load. CoreXY employs a more complex, dual-belt system optimized for balanced distribution of forces, delivering smoother and more reliable motion, making it ideal for your high-precision robotics projects.

How H-Bot Mechanism Works

The H-Bot mechanism operates using two motors positioned on a single axis that control a belt system arranged in an H-shaped configuration, allowing precise movement along the X and Y axes. This design reduces mechanical complexity and offers a lightweight, rigid structure, ideal for rapid and accurate positioning in 3D printers and CNC machines. Your projects can benefit from the H-Bot's direct drive approach, providing consistent motion control with fewer moving parts compared to CoreXY systems.

CoreXY Mechanism Explained

CoreXY mechanisms utilize two stationary motors and a system of belts arranged in a crossed configuration to deliver precise, lightweight, and high-speed motion along the X and Y axes. This design reduces moving mass compared to the H-Bot, which has motors mounted on moving parts, often resulting in increased inertia and lower acceleration. Understanding the CoreXY mechanism helps you optimize your robotic system for improved accuracy and efficiency in applications requiring rapid, precise positioning.

Key Differences Between H-Bot and CoreXY

The H-Bot uses a single continuous belt system arranged in an "H" shape, enabling simpler mechanics but resulting in uneven belt tension and potential racking issues during movement. CoreXY employs two independent belts arranged in a crossed configuration, providing better distribution of forces and increased positional accuracy by minimizing skew and twisting. CoreXY's design generally offers higher rigidity and smoother motion, making it preferable for precision 3D printing and CNC applications compared to the H-Bot.

Precision and Accuracy Comparison

H-Bot and CoreXY robots differ significantly in precision and accuracy due to their mechanical designs. CoreXY systems utilize a kinematic arrangement that reduces motor-induced racking and belt tension inconsistencies, resulting in higher positional accuracy and repeatability. Your choice of robot should consider CoreXY's superior precision for detailed tasks, while H-Bot may be suitable for less demanding applications.

Speed and Efficiency Analysis

The CoreXY robot architecture offers superior speed and efficiency compared to the H-Bot design due to its fixed motor placement and reduced moving mass, which minimizes inertia and vibration. H-Bot systems suffer from racking and skew issues caused by belt arrangement, limiting their high-speed performance and precision. For your projects requiring rapid acceleration and consistent accuracy, CoreXY provides a more reliable solution.

Pros and Cons of H-Bot Systems

H-Bot systems offer a simple belt design with fewer components, leading to easier calibration and lower manufacturing costs. However, the main drawback is their susceptibility to racking forces, which can reduce precision and cause mechanical strain during high-speed or heavy-load operations. Your choice depends on balancing cost-efficiency against motion accuracy and mechanical stability requirements.

Advantages and Drawbacks of CoreXY Designs

CoreXY designs offer high-speed, precise movement due to their rigid frame and lightweight moving parts, enhancing 3D printing and CNC machining efficiency. The mechanical simplicity and reduced belt tension in CoreXY systems lower maintenance needs but require careful calibration to avoid print defects. Your choice depends on prioritizing speed and accuracy against potential complexity in assembly compared to H-Bot configurations.

Choosing the Right Robotic System: H-Bot vs CoreXY

H-Bot and CoreXY robotic systems differ primarily in their belt configurations, impacting precision and rigidity in motion control. CoreXY offers superior mechanical stability due to its fixed motor mounts and reduced belt tension variations, making it ideal for high-speed and high-accuracy applications. When choosing the right robotic system, consider Your need for precision, ease of maintenance, and the specific mechanical advantages each design provides to optimize performance.

H-Bot vs CoreXY Robot Infographic

libmatt.com

libmatt.com