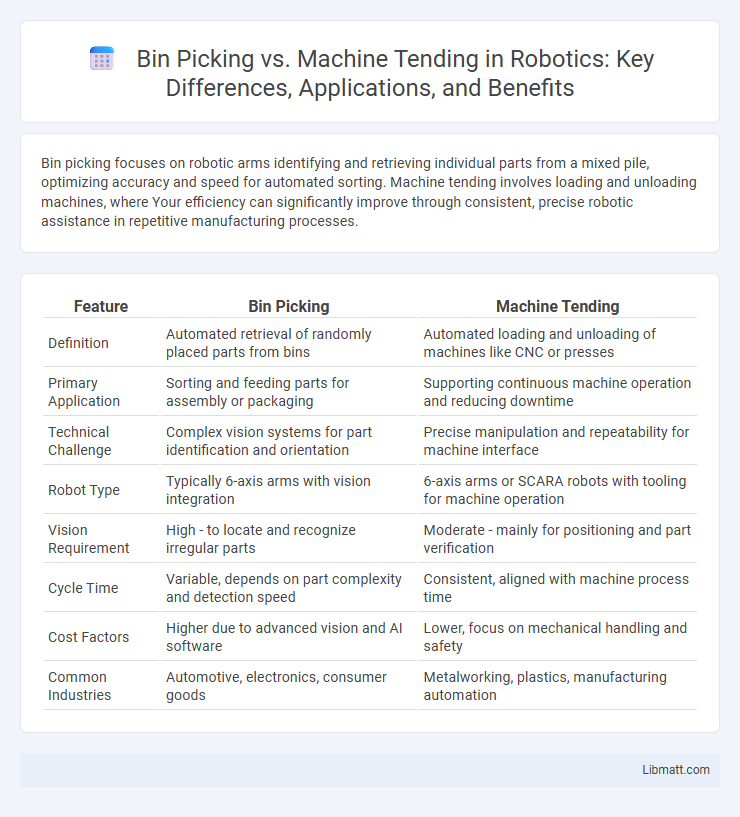

Bin picking focuses on robotic arms identifying and retrieving individual parts from a mixed pile, optimizing accuracy and speed for automated sorting. Machine tending involves loading and unloading machines, where Your efficiency can significantly improve through consistent, precise robotic assistance in repetitive manufacturing processes.

Table of Comparison

| Feature | Bin Picking | Machine Tending |

|---|---|---|

| Definition | Automated retrieval of randomly placed parts from bins | Automated loading and unloading of machines like CNC or presses |

| Primary Application | Sorting and feeding parts for assembly or packaging | Supporting continuous machine operation and reducing downtime |

| Technical Challenge | Complex vision systems for part identification and orientation | Precise manipulation and repeatability for machine interface |

| Robot Type | Typically 6-axis arms with vision integration | 6-axis arms or SCARA robots with tooling for machine operation |

| Vision Requirement | High - to locate and recognize irregular parts | Moderate - mainly for positioning and part verification |

| Cycle Time | Variable, depends on part complexity and detection speed | Consistent, aligned with machine process time |

| Cost Factors | Higher due to advanced vision and AI software | Lower, focus on mechanical handling and safety |

| Common Industries | Automotive, electronics, consumer goods | Metalworking, plastics, manufacturing automation |

Introduction to Bin Picking and Machine Tending

Bin picking involves robotic systems using advanced vision and AI to identify and grasp random parts from a container, optimizing material handling in manufacturing. Machine tending refers to automating the loading and unloading of machines like CNCs, enhancing production efficiency and reducing manual labor. Understanding your operation's material handling needs will help determine whether bin picking or machine tending provides the best solution for improving workflow and productivity.

Key Differences Between Bin Picking and Machine Tending

Bin picking involves robotic systems automatically identifying and extracting parts from a bulk container, focusing on high variability and randomness in part orientation for efficient sorting. Machine tending centers on loading and unloading machines, such as CNC machines or presses, with precise, repetitive placement and retrieval tasks often integrated into manufacturing workflows. Your choice between these applications depends on your operational needs for flexibility in part handling versus consistency in machine operation automation.

Core Technologies Involved in Both Processes

Bin picking primarily relies on advanced 3D vision systems, including structured light and stereo cameras, combined with machine learning algorithms for object recognition and pose estimation. Machine tending integrates robotic arms with force sensors and programmable logic controllers (PLCs) to accurately load and unload parts while maintaining synchronization with CNC machines or other automated equipment. Both processes benefit from automation software platforms that optimize task planning and real-time adjustments to enhance efficiency and precision.

Typical Applications of Bin Picking

Typical applications of bin picking include automated sorting, packaging, and assembly lines where robots identify and grasp randomly oriented objects from bulk containers. Common industries leveraging bin picking are automotive manufacturing, electronics, and consumer goods, enhancing efficiency in handling diverse parts and reducing manual labor. Your production can benefit from improved accuracy and cycle times by integrating bin picking systems tailored to high-mix, low-volume workflows.

Common Use Cases for Machine Tending

Machine tending is commonly used in applications requiring precise loading and unloading of CNC machines, injection molding machines, and stamping presses to enhance productivity and reduce human error. It is ideal for repetitive tasks such as part placement, tool changes, and quality inspection within manufacturing lines. This automation streamlines workflows in automotive, electronics, and aerospace industries, improving safety and operational efficiency.

Benefits and Challenges of Bin Picking

Bin picking offers automated precision in handling randomly placed parts, significantly boosting efficiency and reducing manual labor costs in manufacturing environments. Its benefits include enhanced accuracy, faster cycle times, and improved safety by minimizing human intervention in repetitive tasks. Challenges stem from complex object recognition, variability in part orientation, and the need for advanced vision systems to ensure reliable gripping and placement.

Advantages and Limitations of Machine Tending

Machine tending offers precise and consistent handling of parts in manufacturing, significantly reducing human error and improving safety in hazardous environments. However, it can be limited by its need for customized tooling and programming, which may increase setup time and reduce flexibility for different tasks. The integration of machine tending systems enhances productivity but requires substantial initial investment and skilled maintenance for optimal performance.

Integration with Robotics and Automation

Bin picking leverages advanced robotics integrated with AI-driven vision systems to identify and grasp randomly oriented objects, enhancing automation in complex sorting tasks. Machine tending typically involves robotic arms performing repetitive actions such as loading and unloading parts in CNC machines, optimizing production line efficiency through precise automation. Your choice between bin picking and machine tending should consider the level of robotic integration required for your specific manufacturing or logistics automation needs.

Cost and ROI Comparison: Bin Picking vs Machine Tending

Bin picking typically involves higher upfront costs due to advanced vision systems and specialized grippers, while machine tending often requires less investment in automation hardware but may involve more programming and setup tailored to specific machines. Your ROI on bin picking can be faster in environments with high variability and random part presentation, enhancing flexibility and reducing manual sorting time. Machine tending yields better ROI in repetitive, high-volume production lines by maximizing machine uptime and minimizing labor costs.

Choosing the Right Solution for Your Manufacturing Needs

Bin picking automates the process of identifying and retrieving randomly placed parts from a container, ideal for high-mix, low-volume operations requiring flexibility and precision. Machine tending involves loading and unloading parts to and from production machinery, enhancing throughput for repetitive, high-volume tasks. Evaluating your manufacturing workflow, part variability, and production targets helps determine whether bin picking or machine tending offers the optimal automation solution for your specific needs.

Bin picking vs Machine tending Infographic

libmatt.com

libmatt.com