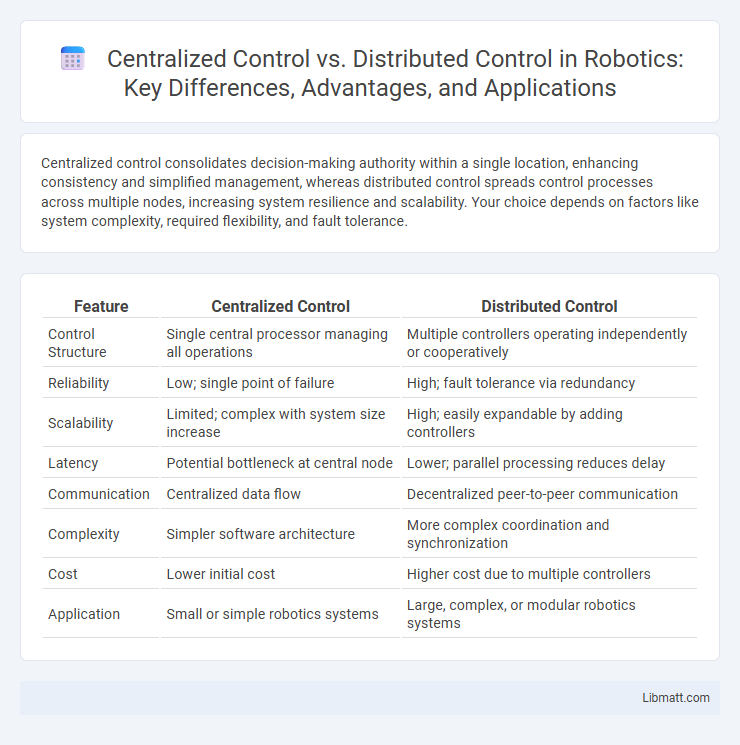

Centralized control consolidates decision-making authority within a single location, enhancing consistency and simplified management, whereas distributed control spreads control processes across multiple nodes, increasing system resilience and scalability. Your choice depends on factors like system complexity, required flexibility, and fault tolerance.

Table of Comparison

| Feature | Centralized Control | Distributed Control |

|---|---|---|

| Control Structure | Single central processor managing all operations | Multiple controllers operating independently or cooperatively |

| Reliability | Low; single point of failure | High; fault tolerance via redundancy |

| Scalability | Limited; complex with system size increase | High; easily expandable by adding controllers |

| Latency | Potential bottleneck at central node | Lower; parallel processing reduces delay |

| Communication | Centralized data flow | Decentralized peer-to-peer communication |

| Complexity | Simpler software architecture | More complex coordination and synchronization |

| Cost | Lower initial cost | Higher cost due to multiple controllers |

| Application | Small or simple robotics systems | Large, complex, or modular robotics systems |

Introduction to Control Systems

Control systems regulate the behavior of devices or processes by managing inputs and outputs through feedback mechanisms. Centralized control systems feature a single controller handling all decision-making tasks, providing simplified management but risking a single point of failure. Distributed control systems allocate control functions across multiple controllers, enhancing system reliability and scalability while reducing the impact of individual component failures.

Overview of Centralized Control

Centralized control systems consolidate decision-making authority in a single central unit, streamlining management and coordination across all connected devices and processes. This approach enhances consistency, simplifies monitoring, and can improve response times by allowing a single point to analyze data and execute commands. You gain improved oversight and simplified maintenance, making centralized control ideal for applications requiring uniformity and tight supervision.

Understanding Distributed Control

Distributed control systems (DCS) feature multiple controllers spread across various locations, enhancing system reliability and scalability compared to centralized control. By decentralizing control functions, DCS minimizes single points of failure and enables real-time data processing closer to the process, improving overall efficiency. Understanding distributed control empowers you to optimize operations with greater flexibility and fault tolerance in complex industrial environments.

Key Differences: Centralized vs Distributed

Centralized control consolidates decision-making authority within a single central system, enabling streamlined management but posing risks of a single point of failure. Distributed control spreads decision-making across multiple interconnected nodes, enhancing system resilience and scalability by avoiding bottlenecks. Your choice between centralized and distributed control impacts system reliability, fault tolerance, and responsiveness, depending on organizational needs and complexity.

Advantages of Centralized Control

Centralized control systems offer streamlined decision-making by consolidating authority, which enhances coordination and consistency across an organization. They simplify management through a single point of control, reducing the risk of conflicting actions and improving efficiency. Your operations benefit from easier implementation of policies and quicker enforcement of standards within a centralized framework.

Benefits of Distributed Control

Distributed Control Systems (DCS) enhance operational reliability by decentralizing decision-making processes, reducing single points of failure inherent in centralized control systems. They improve scalability and flexibility, allowing for easier expansion and adaptation to complex industrial processes. Furthermore, distributed control enables faster local responses and improved fault tolerance, leading to increased efficiency and reduced downtime.

Challenges and Limitations of Each Approach

Centralized control systems face challenges such as single points of failure, limited scalability, and latency issues due to dependency on a central controller. Distributed control systems encounter limitations including complexity in coordination, higher implementation costs, and potential inconsistencies caused by asynchronous communication across nodes. Both approaches must balance trade-offs between control efficiency, fault tolerance, and system robustness in dynamic environments.

Use Cases and Industry Applications

Centralized control systems are extensively utilized in manufacturing plants and power generation facilities where uniform decision-making and streamlined monitoring are essential for operational efficiency. Distributed control systems (DCS) excel in complex industrial environments such as chemical processing, oil refining, and large-scale HVAC systems by enabling localized control that improves system reliability and reduces response time. Your choice between centralized and distributed control depends on the specific use case requirements, including scalability, fault tolerance, and the need for real-time process adjustments.

Security Considerations in Control Architectures

Centralized control systems concentrate decision-making authority, which can create a single point of failure and increase vulnerability to cyberattacks. Distributed control architectures enhance security by decentralizing control functions, reducing the risk of total system compromise and enabling faster threat isolation. Your choice between these architectures should weigh the security trade-offs, with distributed control generally offering greater resilience against targeted cyber threats.

Future Trends in Control System Design

Future trends in control system design emphasize the integration of distributed control architectures to enhance system resilience, scalability, and real-time responsiveness across industrial automation and smart grid applications. Advanced edge computing and IoT technologies enable decentralized decision-making, reducing latency and improving fault tolerance compared to traditional centralized control systems. Machine learning algorithms are increasingly incorporated to optimize control parameters dynamically, driving a shift towards hybrid control models that balance central coordination with distributed autonomy.

Centralized Control vs Distributed Control Infographic

libmatt.com

libmatt.com