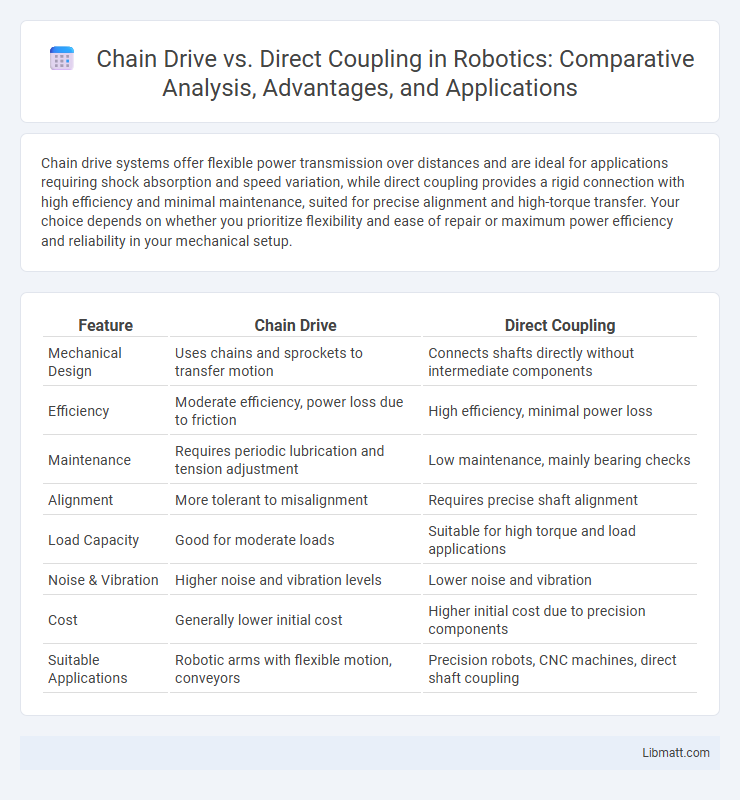

Chain drive systems offer flexible power transmission over distances and are ideal for applications requiring shock absorption and speed variation, while direct coupling provides a rigid connection with high efficiency and minimal maintenance, suited for precise alignment and high-torque transfer. Your choice depends on whether you prioritize flexibility and ease of repair or maximum power efficiency and reliability in your mechanical setup.

Table of Comparison

| Feature | Chain Drive | Direct Coupling |

|---|---|---|

| Mechanical Design | Uses chains and sprockets to transfer motion | Connects shafts directly without intermediate components |

| Efficiency | Moderate efficiency, power loss due to friction | High efficiency, minimal power loss |

| Maintenance | Requires periodic lubrication and tension adjustment | Low maintenance, mainly bearing checks |

| Alignment | More tolerant to misalignment | Requires precise shaft alignment |

| Load Capacity | Good for moderate loads | Suitable for high torque and load applications |

| Noise & Vibration | Higher noise and vibration levels | Lower noise and vibration |

| Cost | Generally lower initial cost | Higher initial cost due to precision components |

| Suitable Applications | Robotic arms with flexible motion, conveyors | Precision robots, CNC machines, direct shaft coupling |

Introduction to Power Transmission Methods

Chain drive and direct coupling are fundamental power transmission methods in mechanical systems, each offering distinct advantages based on application requirements. Chain drives provide flexibility and efficient torque transfer across varying distances through interlinked rollers and sprockets, ideal for motorcycles and conveyor systems. Direct coupling connects shafts in alignment, enabling high-efficiency power transfer with minimal energy loss, commonly used in industrial machinery and electric motors.

Overview of Chain Drive Systems

Chain drive systems use a series of linked metal chains and sprockets to transmit mechanical power between rotating shafts with precise synchronization. Common in industrial machinery and motorcycles, chain drives offer high torque capacity and durability while allowing for flexible center distances. Your equipment benefits from chain drives due to their efficiency in power transfer and ease of maintenance compared to direct coupling systems.

Key Features of Direct Coupling

Direct coupling features a rigid connection between shafts, ensuring precise alignment and efficient power transmission with minimal energy loss. It eliminates the need for additional components like chains or belts, reducing maintenance and increasing system reliability. Your machinery benefits from reduced vibration and higher torque capacity due to the solid, direct link between driving and driven elements.

Efficiency Comparison: Chain Drive vs Direct Coupling

Chain drives typically exhibit efficiency levels ranging from 95% to 98%, influenced by factors like lubrication, tension, and wear, while direct coupling achieves near 100% efficiency due to the absence of intermediary components. Your choice affects power transmission losses, with chain drives experiencing slight frictional and mechanical losses compared to the minimal energy loss in direct coupling systems. For applications demanding maximum efficiency and minimal maintenance, direct coupling is often preferred, whereas chain drives offer flexibility and ease of replacement.

Installation and Maintenance Requirements

Chain drive systems demand precise alignment and tension adjustment during installation to ensure optimal performance and longevity, often requiring periodic lubrication and tension checks for maintenance. Direct coupling installations are simpler and faster, involving direct shaft mating with minimal alignment tools, but they require careful monitoring for wear and potential misalignment to prevent equipment damage. Maintenance for direct couplings typically involves inspection for cracks and replacement of flexible elements, whereas chain drives necessitate ongoing lubrication and periodic chain replacement to maintain efficiency.

Cost Analysis: Initial and Long-Term Expenses

Chain drives generally have lower initial costs due to inexpensive components and simpler installation compared to direct coupling systems, which require precise alignment and higher-quality materials. Long-term expenses for chain drives include frequent maintenance and replacement of worn chains and sprockets, often increasing operational costs. Direct coupling offers reduced maintenance costs and longer service life but involves higher upfront investment and potentially costly repairs if misalignment occurs.

Performance Under Variable Loads

Chain drives provide reliable performance under variable loads by maintaining consistent torque transmission and accommodating load fluctuations with minimal slippage. Direct coupling offers superior efficiency and minimal power loss but can be less forgiving under sudden load variations due to its rigid connection. For applications experiencing frequent load changes, chain drives ensure durability and flexibility, while direct coupling is optimal for steady load conditions requiring precise motion control.

Noise, Vibration, and Operational Smoothness

Chain drives typically generate higher noise and vibration levels due to metal-on-metal contact and chain tension fluctuations, impacting operational smoothness. Direct coupling systems offer quieter performance with minimal vibration by providing rigid connections that ensure consistent torque transmission and balanced rotation. The choice between chain drive and direct coupling directly affects machinery noise control, vibration reduction, and overall smooth operation efficiency.

Application Suitability and Industry Use Cases

Chain drives are ideal for applications requiring flexibility in distance between shafts and the ability to absorb shock loads, commonly used in automotive, agricultural machinery, and conveyor systems. Direct coupling offers precise alignment and efficient power transmission, making it suitable for high-speed industrial equipment, pumps, and compressors. Your choice depends on the specific requirements of torque, speed, and alignment within industries such as manufacturing, transportation, and heavy machinery.

Conclusion: Choosing the Right System for Your Needs

Chain drives offer flexibility and ease of maintenance, making them suitable for applications requiring variable distances between shafts and moderate power transmission. Direct coupling provides higher efficiency and precise alignment, ideal for high-speed operations with minimal power loss and low maintenance requirements. Selecting the right system depends on factors such as operational speed, power requirements, space constraints, and maintenance preferences.

Chain Drive vs Direct Coupling Infographic

libmatt.com

libmatt.com