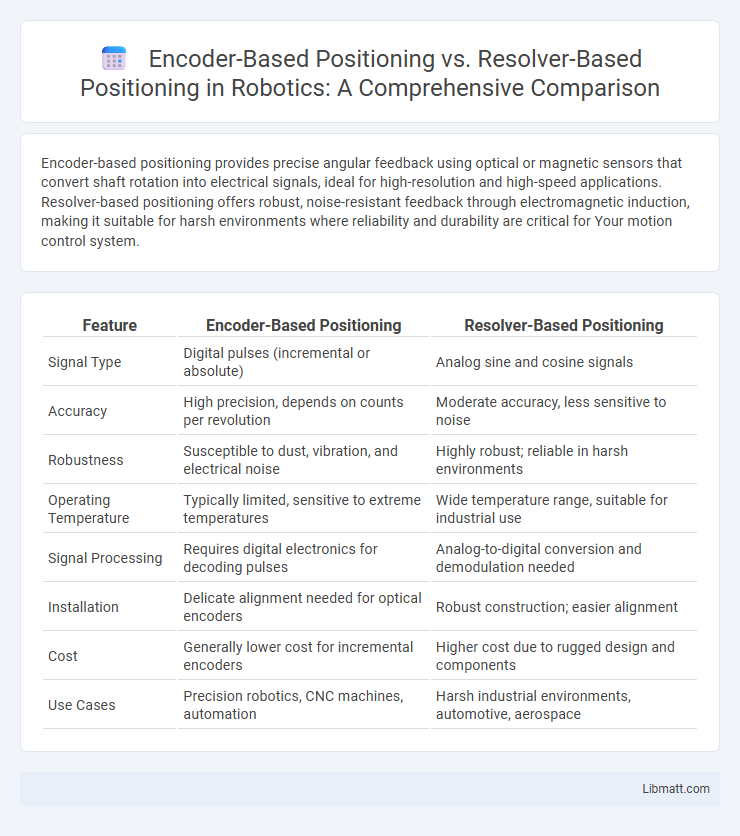

Encoder-based positioning provides precise angular feedback using optical or magnetic sensors that convert shaft rotation into electrical signals, ideal for high-resolution and high-speed applications. Resolver-based positioning offers robust, noise-resistant feedback through electromagnetic induction, making it suitable for harsh environments where reliability and durability are critical for Your motion control system.

Table of Comparison

| Feature | Encoder-Based Positioning | Resolver-Based Positioning |

|---|---|---|

| Signal Type | Digital pulses (incremental or absolute) | Analog sine and cosine signals |

| Accuracy | High precision, depends on counts per revolution | Moderate accuracy, less sensitive to noise |

| Robustness | Susceptible to dust, vibration, and electrical noise | Highly robust; reliable in harsh environments |

| Operating Temperature | Typically limited, sensitive to extreme temperatures | Wide temperature range, suitable for industrial use |

| Signal Processing | Requires digital electronics for decoding pulses | Analog-to-digital conversion and demodulation needed |

| Installation | Delicate alignment needed for optical encoders | Robust construction; easier alignment |

| Cost | Generally lower cost for incremental encoders | Higher cost due to rugged design and components |

| Use Cases | Precision robotics, CNC machines, automation | Harsh industrial environments, automotive, aerospace |

Introduction to Positioning Systems

Encoder-based positioning systems use optical or magnetic sensors to convert mechanical position into digital signals, enabling precise measurement of angular or linear displacement. Resolver-based positioning systems employ rotary transformers to provide analog signals representing shaft position, offering robustness against electrical noise and harsh environments. Both technologies are critical in industrial automation, robotics, and motor control applications, with encoders favored for high precision and resolvers for durability.

Overview of Encoder-Based Positioning

Encoder-based positioning utilizes optical or magnetic sensors to convert rotational or linear motion into digital signals, providing precise angular or linear position feedback. Commonly used in robotics, CNC machinery, and industrial automation, these encoders offer high resolution and accuracy by measuring incremental or absolute positions. The system's effectiveness depends on factors such as encoder type, resolution, and application-specific environmental conditions.

Fundamentals of Resolver-Based Positioning

Resolver-based positioning operates on the principle of electromagnetic induction, using a rotor and stator to generate sine and cosine signals corresponding to angular displacement. These analog signals are converted into digital data through signal processing techniques to accurately determine the rotor's position. This method offers high reliability and robustness in harsh environments due to its non-contact design and inherent resistance to electrical noise.

Key Differences: Encoders vs Resolvers

Encoders provide digital position feedback by converting shaft rotation into a series of electronic pulses, offering high resolution and accuracy in various industrial applications. Resolvers function as rotary transformers producing analog signals based on the rotor's angle, excelling in harsh environments due to their robustness and reliability under extreme temperatures and vibrations. Key differences include encoders' susceptibility to electrical noise and limited durability, whereas resolvers deliver continuous absolute position data with superior resistance to shock and wear.

Accuracy and Resolution Comparison

Encoder-based positioning systems typically offer higher resolution and greater positional accuracy due to their ability to provide precise digital feedback through optical or magnetic sensors. Resolver-based positioning, while robust and reliable in harsh environments, generally has lower resolution and accuracy, as it relies on analog signal processing which can introduce noise and signal degradation. Your choice should consider whether ultra-high precision or environmental durability is the priority for your application.

Reliability in Harsh Environments

Encoder-based positioning systems offer moderate reliability in harsh environments but are susceptible to contamination from dust, moisture, and vibrations, which can degrade signal accuracy over time. Resolver-based positioning provides superior robustness due to its magnetic coupling and inherent immunity to contaminants, temperature extremes, and electromagnetic interference, making it ideal for industrial and automotive applications. This increased durability ensures stable performance and reduced maintenance costs in challenging operational conditions.

Installation and Maintenance Considerations

Encoder-based positioning systems require precise alignment during installation to ensure accurate signal output, making initial setup more time-consuming but offering easier troubleshooting and less frequent calibration. Resolver-based positioning systems feature robust mechanical construction that withstands harsh environments, reducing maintenance needs but often requiring specialized tools for installation and repair. Your choice depends on balancing the ease of installation and the long-term reliability tailored to your application's environmental conditions.

Integration with Control Systems

Encoder-based positioning offers seamless integration with control systems through digital or analog signals, enabling precise feedback and easy compatibility with PLCs, CNC machines, and motion controllers. Resolver-based positioning provides robust integration in harsh environments by using analog sinusoidal signals, ensuring reliable feedback even under extreme temperatures, vibrations, and electrical noise. Both technologies support closed-loop control, but encoder integration is often preferred for high-resolution, high-speed applications due to straightforward interfacing and calibration.

Cost Implications and ROI

Encoder-based positioning systems generally offer lower upfront costs and simpler integration compared to resolver-based systems, making them a cost-effective choice for applications requiring moderate precision. Resolver-based positioning, while more expensive initially due to robust design and higher accuracy in harsh environments, often yields a superior ROI in demanding industrial settings where reliability and minimal downtime are critical. Your decision should weigh the total cost of ownership against performance requirements to maximize overall investment returns.

Choosing the Right Positioning System

Choosing the right positioning system hinges on specific application requirements such as precision, environmental conditions, and cost constraints. Encoder-based positioning excels in applications demanding high resolution and fast response times, ideal for clean and controlled environments. Resolver-based positioning offers robust performance in harsh conditions with high vibration and temperature variations, providing reliable absolute position feedback without magnetic interference.

Encoder-based positioning vs Resolver-based positioning Infographic

libmatt.com

libmatt.com