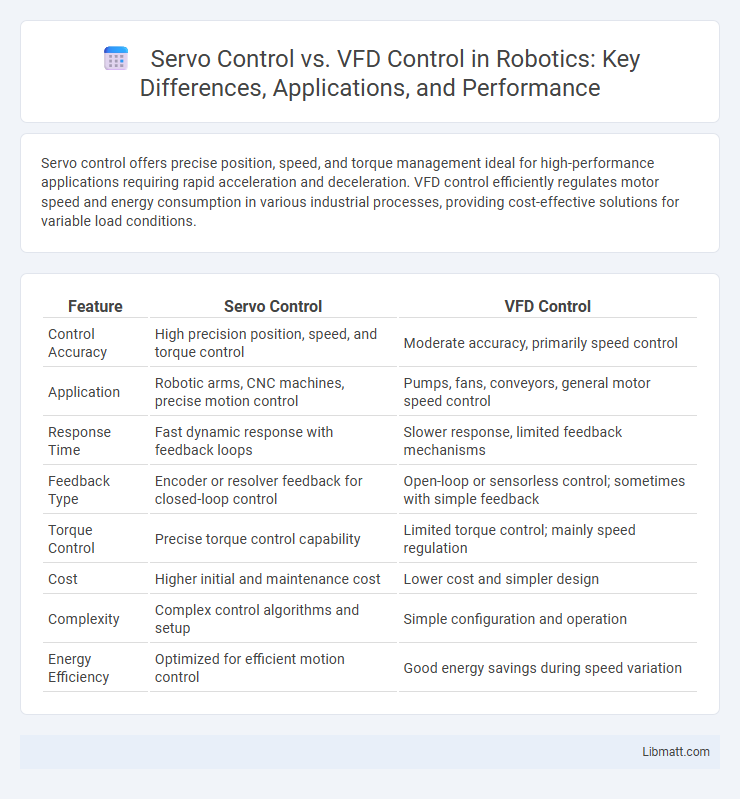

Servo control offers precise position, speed, and torque management ideal for high-performance applications requiring rapid acceleration and deceleration. VFD control efficiently regulates motor speed and energy consumption in various industrial processes, providing cost-effective solutions for variable load conditions.

Table of Comparison

| Feature | Servo Control | VFD Control |

|---|---|---|

| Control Accuracy | High precision position, speed, and torque control | Moderate accuracy, primarily speed control |

| Application | Robotic arms, CNC machines, precise motion control | Pumps, fans, conveyors, general motor speed control |

| Response Time | Fast dynamic response with feedback loops | Slower response, limited feedback mechanisms |

| Feedback Type | Encoder or resolver feedback for closed-loop control | Open-loop or sensorless control; sometimes with simple feedback |

| Torque Control | Precise torque control capability | Limited torque control; mainly speed regulation |

| Cost | Higher initial and maintenance cost | Lower cost and simpler design |

| Complexity | Complex control algorithms and setup | Simple configuration and operation |

| Energy Efficiency | Optimized for efficient motion control | Good energy savings during speed variation |

Introduction to Servo and VFD Controls

Servo control systems provide precise position, speed, and torque regulation using feedback mechanisms, making them ideal for applications requiring high accuracy and dynamic response. Variable Frequency Drives (VFD) control the speed of AC motors by varying the frequency and voltage, optimizing energy consumption and enhancing motor performance in industrial processes. Understanding these control methods helps you select the right solution for efficient and accurate motor operation.

Fundamental Principles of Servo Control

Servo control operates by continuously monitoring the actual position, velocity, or torque of a motor and comparing it to a desired setpoint using feedback sensors such as encoders or resolvers. The system uses a closed-loop control algorithm, typically a PID controller, to minimize error by adjusting the motor input precisely and in real-time. This enables high-accuracy positioning, rapid response, and dynamic load handling critical for robotics, CNC machines, and precise automation applications.

Basic Working of VFD Control Systems

VFD control systems regulate motor speed by adjusting the voltage and frequency supplied to the motor, allowing precise speed modulation and energy efficiency. Using pulse width modulation (PWM) techniques, VFDs convert input power into variable frequency output, controlling motor torque and speed dynamically. This enables smooth acceleration, deceleration, and reduced mechanical stress compared to traditional motor control methods.

Key Differences Between Servo and VFD Drives

Servo drives provide precise position, speed, and torque control using feedback from encoders or resolvers, making them ideal for applications requiring high accuracy and dynamic response. Variable Frequency Drives (VFDs) regulate motor speed by adjusting the frequency and voltage supplied to induction motors, optimizing energy consumption for constant torque applications. The key differences include feedback mechanisms, control precision, and typical use cases, with servos excelling in positioning tasks and VFDs favored for energy-efficient speed control in industrial processes.

Precision and Accuracy in Motion Control

Servo control systems deliver superior precision and accuracy in motion control by utilizing closed-loop feedback mechanisms that constantly adjust position, speed, and torque. Variable Frequency Drives (VFDs) primarily control motor speed by adjusting power frequency but generally lack the high level of positional accuracy achievable with servos. For applications demanding exact positioning and smooth dynamic response, servo control offers significantly enhanced motion control performance compared to VFD control.

Speed and Torque Control Capabilities

Servo control systems provide precise and dynamic speed and torque regulation, offering high responsiveness and accuracy ideal for applications requiring rapid acceleration and deceleration. VFD control adjusts motor speed by varying frequency and voltage, delivering efficient torque control but with less precision compared to servo drives. Your choice depends on the need for exact speed and torque management, with servos excelling in complex motion control and VFDs suited for general motor speed adjustments.

Applications: Where Servo and VFD Excel

Servo control systems excel in precision applications such as robotics, CNC machinery, and automated assembly lines where exact position, speed, and torque control are critical. VFD (Variable Frequency Drive) control is ideal for pumping, HVAC systems, conveyors, and fans that require energy-efficient speed regulation and simple torque control. Industries leverage servos for high-performance tasks requiring rapid acceleration and deceleration, while VFDs are preferred for cost-effective motor speed adjustments in continuous or variable load conditions.

Energy Efficiency and Power Consumption

Servo control systems deliver precise motion with high energy efficiency by adjusting power output based on load requirements, minimizing unnecessary energy use. Variable Frequency Drives (VFDs) optimize power consumption effectively by modulating motor speed and torque, reducing energy waste during partial load operation. Both technologies enhance overall system efficiency, but servo controls typically achieve greater precision and lower energy losses in dynamic, high-accuracy applications.

Cost Considerations and ROI

Servo control systems typically incur higher initial costs due to precision components and advanced feedback mechanisms, yet they offer superior performance in applications requiring exact positioning and speed control, leading to faster ROI in specialized industries. Variable Frequency Drives (VFDs) present lower upfront expenses and energy savings by efficiently controlling motor speed, which suits general-purpose applications and yields a steady ROI through reduced operating costs. Evaluating application requirements, load variability, and desired accuracy is critical for cost-effective investment and maximizing return on investment in motor control solutions.

Choosing the Right Solution for Your Needs

Servo control systems offer precise positioning and high-speed response, making them ideal for applications requiring exact motion control and repeatability. VFD control optimizes motor speed and energy efficiency, suited for variable torque loads and HVAC systems where smooth speed regulation is essential. Selecting the right solution depends on factors like load type, precision requirements, and energy consumption goals, ensuring optimal performance and cost-effectiveness.

Servo Control vs VFD Control Infographic

libmatt.com

libmatt.com