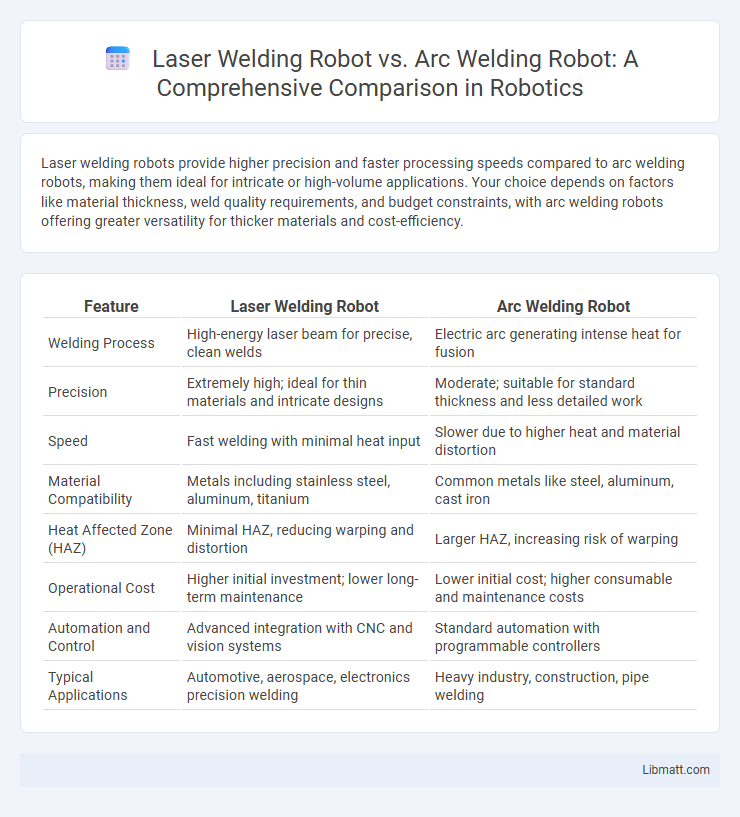

Laser welding robots provide higher precision and faster processing speeds compared to arc welding robots, making them ideal for intricate or high-volume applications. Your choice depends on factors like material thickness, weld quality requirements, and budget constraints, with arc welding robots offering greater versatility for thicker materials and cost-efficiency.

Table of Comparison

| Feature | Laser Welding Robot | Arc Welding Robot |

|---|---|---|

| Welding Process | High-energy laser beam for precise, clean welds | Electric arc generating intense heat for fusion |

| Precision | Extremely high; ideal for thin materials and intricate designs | Moderate; suitable for standard thickness and less detailed work |

| Speed | Fast welding with minimal heat input | Slower due to higher heat and material distortion |

| Material Compatibility | Metals including stainless steel, aluminum, titanium | Common metals like steel, aluminum, cast iron |

| Heat Affected Zone (HAZ) | Minimal HAZ, reducing warping and distortion | Larger HAZ, increasing risk of warping |

| Operational Cost | Higher initial investment; lower long-term maintenance | Lower initial cost; higher consumable and maintenance costs |

| Automation and Control | Advanced integration with CNC and vision systems | Standard automation with programmable controllers |

| Typical Applications | Automotive, aerospace, electronics precision welding | Heavy industry, construction, pipe welding |

Introduction to Welding Robots

Laser welding robots offer precise, high-speed welding with minimal heat distortion, making them ideal for delicate or complex metal components. Arc welding robots provide robust and versatile welding solutions suitable for heavy-duty applications and thicker materials, using electric current to join metals effectively. By understanding these differences, you can select the right welding robot technology to optimize efficiency and quality in your manufacturing processes.

Overview of Laser Welding Robots

Laser welding robots utilize high-intensity laser beams to join metals with precision and speed, offering minimal heat distortion and excellent control over the weld pool. These robots excel in industries requiring fine, intricate welds such as aerospace, automotive, and electronics manufacturing. Compared to arc welding robots, laser welding systems provide faster processing times, higher energy efficiency, and superior weld quality for thin materials and complex geometries.

Overview of Arc Welding Robots

Arc welding robots utilize electric arcs to generate intense heat, enabling precise and efficient joining of metals in industrial applications. These robots excel in welding thicker materials and are widely used in automotive and heavy machinery manufacturing due to their durability and consistent weld quality. Your production line can benefit from arc welding robots' adaptability to diverse metal types and complex geometries, enhancing productivity and reducing manual labor.

Key Differences in Welding Technologies

Laser welding robots utilize concentrated laser beams to achieve precise, high-speed welding with minimal heat distortion, making them ideal for thin materials and intricate components. Arc welding robots rely on an electric arc to generate heat, providing deeper penetration and versatility for thicker metals and varied joint types. The key difference lies in laser welding's superior accuracy and speed versus arc welding's robust adaptability and cost-effectiveness.

Performance and Precision Comparison

Laser welding robots deliver superior precision with focused energy beams enabling minimal thermal distortion and narrow weld seams, ideal for intricate and high-quality applications. Arc welding robots offer robust performance with higher material thickness tolerance, producing strong welds suitable for heavy-duty and large-scale industrial tasks. Laser technology excels in speed and exactness, while arc welding provides versatility and cost-efficiency in diverse manufacturing environments.

Material Compatibility and Applications

Laser welding robots excel in processing thin metals, reflective materials, and complex geometries due to their precise, high-energy beam, making them ideal for electronics, automotive, and aerospace industries. Arc welding robots perform best with thicker metals and heavy-duty applications, using electric arc to join steel, aluminum, and other conductive metals, common in shipbuilding, construction, and heavy machinery manufacturing. Material compatibility dictates the choice: laser welding suits delicate, high-precision parts, while arc welding handles robust, larger workpieces efficiently.

Speed and Efficiency Analysis

Laser welding robots offer significantly higher speeds and precision compared to arc welding robots, enabling faster cycle times and reduced production bottlenecks. Their concentrated heat source minimizes distortion and improves weld quality, leading to greater overall efficiency in high-volume manufacturing. Your choice depends on the specific application requirements, but for rapid, precise welds, laser welding robots often deliver superior performance.

Operational Costs and Maintenance

Laser welding robots generally incur higher initial investment costs but offer lower operational expenses due to faster processing speeds and reduced material waste. Arc welding robots feature more affordable maintenance requirements, as their technology is well-established with readily available parts and simpler repair procedures. Over time, laser welding robots deliver cost efficiencies through energy savings and minimal consumable usage, while arc welding robots benefit from lower upfront expenditures and easier upkeep.

Safety Considerations and Challenges

Laser welding robots offer higher precision and reduced heat input, which lowers the risk of burns and deformation, but require stringent eye protection due to intense laser radiation. Arc welding robots generate more fumes and spatter, posing inhalation hazards and necessitating effective ventilation and protective gear for operators. Your choice should weigh the safety protocols and challenges specific to each technology to ensure a secure working environment.

Choosing the Right Welding Robot for Your Needs

Laser welding robots offer precision and speed ideal for high-volume, detailed tasks, while arc welding robots excel in heavy-duty, thicker metal applications requiring strong welds. Your choice depends on factors like material type, production volume, and weld quality requirements, with laser welding preferred for fine, clean welds and arc welding suited for robust, structural joints. Evaluating these parameters ensures you select the welding robot that optimizes efficiency and quality for your specific manufacturing needs.

Laser Welding Robot vs Arc Welding Robot Infographic

libmatt.com

libmatt.com