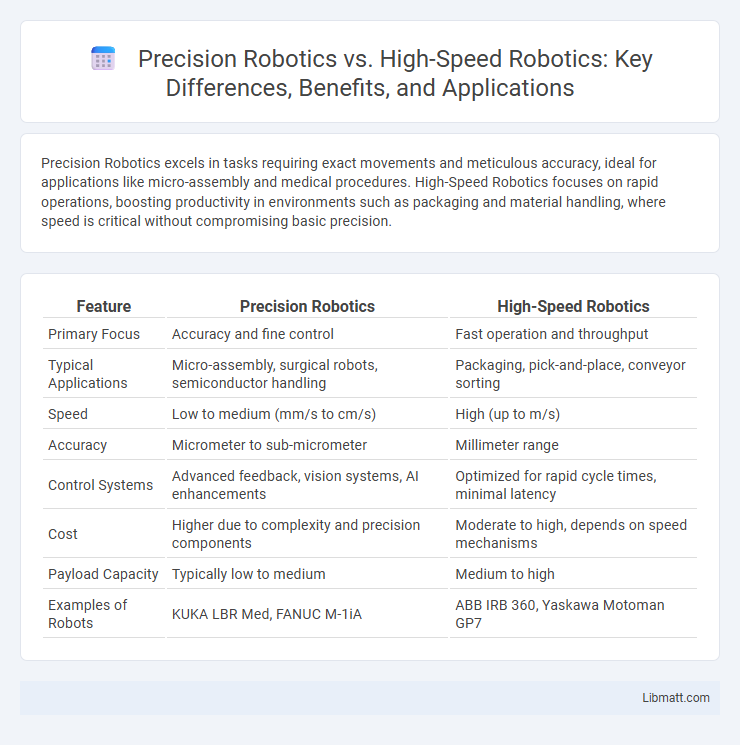

Precision Robotics excels in tasks requiring exact movements and meticulous accuracy, ideal for applications like micro-assembly and medical procedures. High-Speed Robotics focuses on rapid operations, boosting productivity in environments such as packaging and material handling, where speed is critical without compromising basic precision.

Table of Comparison

| Feature | Precision Robotics | High-Speed Robotics |

|---|---|---|

| Primary Focus | Accuracy and fine control | Fast operation and throughput |

| Typical Applications | Micro-assembly, surgical robots, semiconductor handling | Packaging, pick-and-place, conveyor sorting |

| Speed | Low to medium (mm/s to cm/s) | High (up to m/s) |

| Accuracy | Micrometer to sub-micrometer | Millimeter range |

| Control Systems | Advanced feedback, vision systems, AI enhancements | Optimized for rapid cycle times, minimal latency |

| Cost | Higher due to complexity and precision components | Moderate to high, depends on speed mechanisms |

| Payload Capacity | Typically low to medium | Medium to high |

| Examples of Robots | KUKA LBR Med, FANUC M-1iA | ABB IRB 360, Yaskawa Motoman GP7 |

Understanding Precision Robotics

Precision robotics specializes in tasks requiring meticulous accuracy and fine motor control, often used in medical surgery, electronics assembly, and laboratory automation. These robots utilize advanced sensors and algorithms to achieve sub-millimeter positioning, ensuring consistent quality and reducing human error. Understanding precision robotics helps you appreciate their critical role in industries where exact measurements and delicate handling are essential for success.

Key Features of High-Speed Robotics

High-speed robotics are characterized by rapid motion capabilities, enhanced cycle times, and optimized throughput for applications demanding swift, repetitive tasks. These robots incorporate advanced servo motors, lightweight materials, and streamlined designs to minimize inertia and maximize acceleration. Key features include precise timing control, real-time feedback systems, and sophisticated motion algorithms to maintain accuracy at high velocities.

Core Differences: Precision vs High-Speed Robotics

Precision robotics emphasize accuracy and fine control in tasks such as micro-assembly and surgical applications, achieving micron-level positioning with minimal error. High-speed robotics prioritize rapid movement and cycle times, often applied in packaging, sorting, and material handling to maximize throughput. The core difference lies in precision robotics optimizing spatial accuracy and repeatability, while high-speed robotics optimize velocity and operational efficiency.

Applications for Precision Robotics

Precision robotics excel in applications requiring meticulous accuracy and repeatability, such as electronics assembly, medical device manufacturing, and microfabrication. These robots enable your production lines to achieve tight tolerances and high-quality outcomes in tasks like intricate component placement and delicate material handling. Their ability to perform precise movements consistently makes them indispensable in industries where error reduction and product consistency drive competitive advantage.

Industries Benefiting from High-Speed Robotics

High-speed robotics revolutionize industries such as electronics manufacturing, food and beverage packaging, and pharmaceuticals by significantly increasing production rates and enhancing efficiency. These robots excel in tasks requiring rapid, repetitive movements, making them ideal for assembly lines and sorting applications where speed is critical. Your business can gain a competitive edge by integrating high-speed robotics to accelerate processes and reduce operational costs.

Performance Metrics: Accuracy vs Speed

Precision robotics excels in achieving micrometer-level accuracy essential for tasks requiring intricate detail, such as semiconductor manufacturing and surgical applications. High-speed robotics prioritizes rapid cycle times and throughput, reaching speeds exceeding hundreds of operations per minute in assembly lines and packaging industries. Balancing accuracy and speed depends on the specific performance metrics, where precision robots target minimal positional error typically under 0.01 mm, while high-speed robots emphasize operational velocity with cycle times as low as milliseconds.

Challenges in Precision Robotics Implementation

Precision robotics face significant challenges in overcoming sensor accuracy limitations and maintaining consistent calibration to achieve exact movements. High-speed robotics prioritize rapid operation but often sacrifice the fine control demanded in precision tasks, making integration complex. Your choice depends on balancing accuracy requirements with operational speed to address application-specific constraints effectively.

Overcoming Limitations of High-Speed Robotics

Precision robotics addresses the inherent limitations of high-speed robotics by enhancing accuracy and control during rapid movements, ensuring tasks requiring meticulous detail are performed flawlessly. These systems integrate advanced sensors and feedback loops to minimize errors caused by vibration or inertia, which often challenge high-speed robots. By combining speed with enhanced precision, precision robotics expands the applicability of automation in industries such as electronics assembly, medical devices, and intricate manufacturing processes.

Technological Innovations Shaping Both Fields

Precision robotics advances through innovations such as enhanced sensor integration, machine learning algorithms, and micro-actuator technologies that enable meticulous control and accuracy at the sub-millimeter level. High-speed robotics benefits from breakthroughs in lightweight materials, real-time processing systems, and optimized kinematic designs that allow rapid, repetitive motion while maintaining stability and safety. Both fields leverage developments in AI-driven predictive maintenance and advanced control systems, driving efficiency and reliability in industrial automation.

Choosing the Right Robotic Solution for Your Needs

Precision robotics excels in tasks requiring meticulous accuracy and repeatability, ideal for applications like electronics assembly and medical device manufacturing. High-speed robotics prioritize rapid movement and cycle times, making them suitable for packaging, pick-and-place operations, and mass production environments. Evaluating your specific operational requirements, such as tolerances, production volume, and task complexity, is essential to select the optimal robotic solution.

Precision Robotics vs High-Speed Robotics Infographic

libmatt.com

libmatt.com