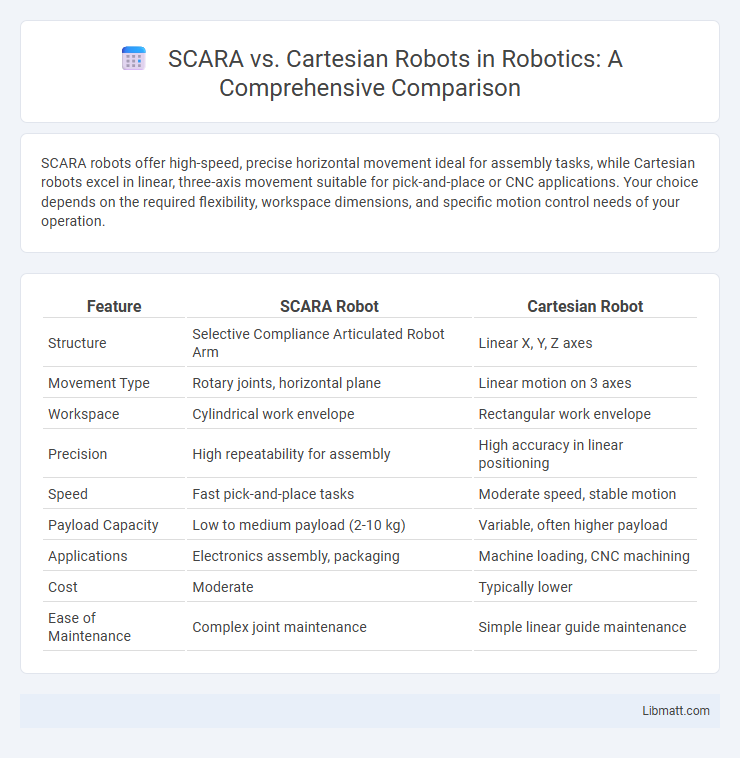

SCARA robots offer high-speed, precise horizontal movement ideal for assembly tasks, while Cartesian robots excel in linear, three-axis movement suitable for pick-and-place or CNC applications. Your choice depends on the required flexibility, workspace dimensions, and specific motion control needs of your operation.

Table of Comparison

| Feature | SCARA Robot | Cartesian Robot |

|---|---|---|

| Structure | Selective Compliance Articulated Robot Arm | Linear X, Y, Z axes |

| Movement Type | Rotary joints, horizontal plane | Linear motion on 3 axes |

| Workspace | Cylindrical work envelope | Rectangular work envelope |

| Precision | High repeatability for assembly | High accuracy in linear positioning |

| Speed | Fast pick-and-place tasks | Moderate speed, stable motion |

| Payload Capacity | Low to medium payload (2-10 kg) | Variable, often higher payload |

| Applications | Electronics assembly, packaging | Machine loading, CNC machining |

| Cost | Moderate | Typically lower |

| Ease of Maintenance | Complex joint maintenance | Simple linear guide maintenance |

Introduction to SCARA and Cartesian Robots

SCARA robots feature a selective compliance articulated arm ideal for precise horizontal movements in assembly tasks, offering high speed and repeatability. Cartesian robots operate on three linear axes (X, Y, Z) and excel in pick-and-place applications requiring straightforward, programmable motion paths. Choosing between SCARA and Cartesian robots depends on your specific application needs, including workspace geometry and precision requirements.

Key Differences Between SCARA and Cartesian Robots

SCARA robots feature cylindrical work envelopes with rotational and vertical movements, ideal for tasks requiring fast, precise assembly and pick-and-place operations. Cartesian robots operate along linear X, Y, and Z axes, offering straightforward programming and superior reach for larger and heavier payloads. The key differences lie in their kinematic structures, with SCARA providing higher speed and agility, while Cartesian robots excel in rigidity and scalability for diverse industrial applications.

Design Principles of SCARA Robots

SCARA robots feature a rigid, articulated arm with two parallel rotary joints designed for horizontal movement, optimizing high-speed pick-and-place tasks and assembly operations. Their design principles emphasize precision, repeatability, and a compact footprint, making them ideal for applications requiring fast cyclical motions along a primarily planar workspace. You benefit from their simplicity in design and efficient control systems, contrasting with Cartesian robots' linear X, Y, and Z axis movements better suited for heavier payloads and larger work volumes.

Structure and Functionality of Cartesian Robots

Cartesian robots feature a straightforward, three-axis linear structure that moves along X, Y, and Z axes, providing high precision and repeatability ideal for pick-and-place or assembly tasks. Their rigid framework supports heavy loads and offers easy programmability, making them suitable for automation requiring linear motion control. Your manufacturing processes benefit from their simple design, which enhances stability and reduces maintenance compared to more complex robot types like SCARA.

Application Areas: SCARA vs Cartesian

SCARA robots excel in high-speed assembly, pick-and-place, and packaging tasks due to their rigid structure and precise horizontal movement, making them ideal for electronics and automotive industries. Cartesian robots offer superior linear motion control and scalability, often utilized in CNC machining, 3D printing, and material handling where large workspaces and vertical movement are critical. Both robot types optimize specific application areas by balancing speed, accuracy, and workspace configuration.

Precision and Speed Comparison

SCARA robots excel in speed due to their lightweight arm and rotational joints, achieving cycle times as low as 0.2 seconds with positional accuracy up to +-0.02 mm. Cartesian robots offer higher precision within linear axes, often reaching repeatability of +-0.01 mm, but typically operate at slower speeds due to their linear motion constraints. For tasks prioritizing rapid pick-and-place operations, SCARA provides better throughput, whereas Cartesian robots are preferred for applications demanding ultra-high precision and stable linear movement.

Flexibility and Workspace Coverage

SCARA robots offer superior flexibility with articulated arms capable of complex lateral movements, making them ideal for tasks requiring precise and agile handling within limited spaces. Cartesian robots provide extensive workspace coverage through linear motion on three perpendicular axes, ensuring high accuracy and repeatability over large, rectangular work areas. Your choice depends on whether you prioritize agile maneuverability or broad, linear reach for your specific application.

Cost and Maintenance Considerations

SCARA robots generally offer lower initial costs and simpler maintenance due to their fewer moving parts and compact design, making them ideal for repetitive pick-and-place tasks. Cartesian robots, while typically more expensive upfront, provide easier scalability and modular maintenance because of their linear axes and standardized components. Choosing between SCARA and Cartesian robots depends on balancing budget constraints with specific application requirements for maintenance efficiency and operational durability.

Industry Adoption Trends

SCARA robots dominate industries requiring high-speed assembly and precision, such as electronics and automotive manufacturing, due to their efficient horizontal articulation. Cartesian robots are widely adopted in packaging, CNC machining, and 3D printing for their linear motion and scalability across large work envelopes. Your choice depends on the specific application demands, with SCARA favored for compact, repetitive tasks and Cartesian preferred for straightforward, heavy-duty operations.

Choosing Between SCARA and Cartesian Robots

Selecting between SCARA and Cartesian robots depends on application-specific requirements such as speed, precision, and workspace geometry. SCARA robots provide high-speed, precise lateral movements ideal for assembly tasks, while Cartesian robots excel in linear motion with large, customizable work envelopes. Evaluating payload capacity, integration complexity, and repeatability ensures optimal choice tailored to industrial automation needs.

SCARA vs Cartesian Infographic

libmatt.com

libmatt.com