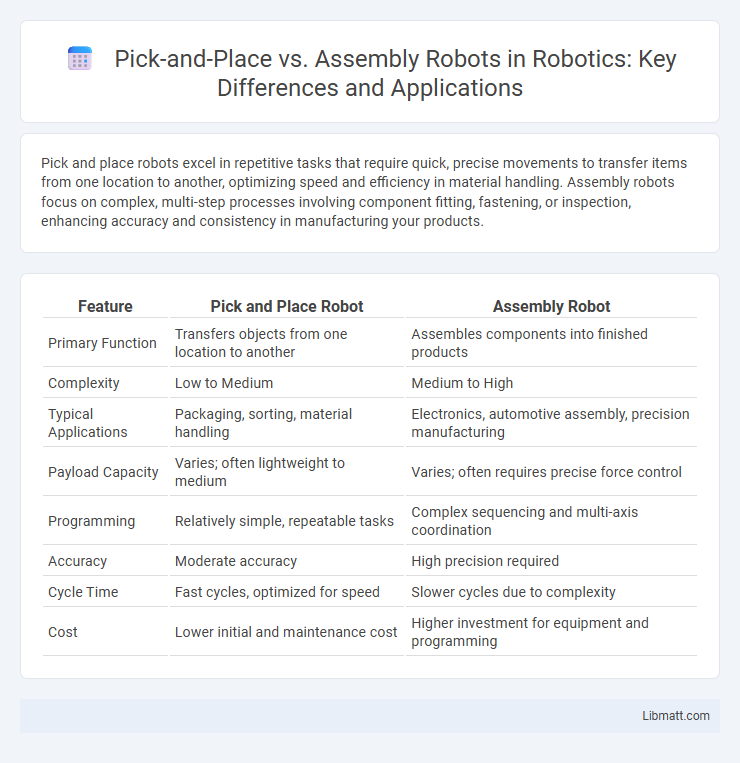

Pick and place robots excel in repetitive tasks that require quick, precise movements to transfer items from one location to another, optimizing speed and efficiency in material handling. Assembly robots focus on complex, multi-step processes involving component fitting, fastening, or inspection, enhancing accuracy and consistency in manufacturing your products.

Table of Comparison

| Feature | Pick and Place Robot | Assembly Robot |

|---|---|---|

| Primary Function | Transfers objects from one location to another | Assembles components into finished products |

| Complexity | Low to Medium | Medium to High |

| Typical Applications | Packaging, sorting, material handling | Electronics, automotive assembly, precision manufacturing |

| Payload Capacity | Varies; often lightweight to medium | Varies; often requires precise force control |

| Programming | Relatively simple, repeatable tasks | Complex sequencing and multi-axis coordination |

| Accuracy | Moderate accuracy | High precision required |

| Cycle Time | Fast cycles, optimized for speed | Slower cycles due to complexity |

| Cost | Lower initial and maintenance cost | Higher investment for equipment and programming |

Introduction to Pick and Place and Assembly Robots

Pick and Place robots are designed to quickly and accurately move objects from one location to another, typically in packaging, sorting, or material handling applications. Assembly robots, on the other hand, perform more complex tasks such as fitting, fastening, or constructing parts in manufacturing processes, enhancing precision and productivity. Understanding the differences helps you select the right robot type for your automation needs.

Key Differences Between Pick and Place and Assembly Robots

Pick and place robots specialize in quickly transferring objects from one location to another with speed and precision, optimizing tasks such as sorting and packaging. Assembly robots perform intricate tasks involving fitting, fastening, or joining components, requiring higher dexterity and adaptability to various parts. Understanding your application's needs helps determine whether speed-focused pick and place automation or detail-oriented assembly robotics is the better solution.

Core Functions of Pick and Place Robots

Pick and Place robots specialize in rapidly and accurately moving objects from one location to another, streamlining repetitive tasks such as sorting, packaging, and material handling in manufacturing. Their core functions include precise object recognition, grasping, and depositing, enhancing production speed and reducing human error. You can optimize your workflow by integrating these robots to handle simple transportation tasks, freeing up human workers for more complex assembly operations.

Core Functions of Assembly Robots

Assembly robots primarily perform tasks such as fastening, welding, and component insertion, integrating various parts to construct a final product. Unlike pick and place robots that focus on simple object transfer, assembly robots handle complex motions requiring precision and consistency. Their core functions include precision alignment, force control, and multi-axis movement to ensure accurate and efficient assembly processes.

Industrial Applications of Pick and Place Robots

Pick and place robots excel in industrial applications by efficiently handling repetitive tasks such as packaging, product sorting, and material transfer on assembly lines. Their precision and speed reduce human error and increase production throughput, making them ideal for electronics manufacturing, food processing, and pharmaceutical industries. Your operations can benefit from these robots by optimizing workflow and minimizing downtime in high-volume environments.

Industrial Applications of Assembly Robots

Assembly robots play a crucial role in automotive manufacturing by accurately and efficiently assembling complex components such as engines and transmissions. They enhance electronics production by handling delicate parts like circuit boards and ensuring precise placement during device assembly. In consumer goods industries, assembly robots streamline processes like packaging and product assembly, significantly reducing cycle times and increasing overall productivity.

Efficiency and Precision Comparison

Pick and Place robots excel in high-speed efficiency for repetitive tasks with exceptional precision, ideal for sorting and packaging applications. Assembly robots offer greater flexibility and accuracy for complex, multi-step operations, enhancing your production quality in intricate manufacturing processes. Choosing between them depends on balancing your need for speed versus detailed precision in workflow efficiency.

Cost Considerations: Pick and Place vs Assembly Robots

Pick and place robots generally have lower initial costs due to simpler design and limited functionality, making them ideal for repetitive tasks with minimal complexity. Assembly robots require higher investment because of advanced precision, multi-axis movement capabilities, and integration with more complex systems, driving up both purchase price and maintenance expenses. Cost considerations must also factor in long-term productivity gains and potential reduction in labor costs, which vary significantly between pick and place and assembly robots.

Choosing the Right Robot for Your Manufacturing Needs

Selecting the right robot for manufacturing depends on specific operational requirements such as speed, precision, and complexity. Pick and Place robots are ideal for high-speed, repetitive tasks involving simple object transfers, optimizing productivity in packaging and sorting applications. Assembly robots provide advanced dexterity and flexibility for intricate tasks, making them suitable for assembling complex components in automotive and electronics industries.

Future Trends in Pick and Place and Assembly Robotics

Future trends in pick and place robotics emphasize increased speed, precision, and integration with AI-driven vision systems to enhance adaptability in dynamic manufacturing environments. Assembly robots are evolving towards greater flexibility and collaboration, incorporating machine learning algorithms to perform complex tasks with minimal human intervention. Both technologies are advancing through IoT connectivity, enabling real-time monitoring and predictive maintenance to improve efficiency and reduce downtime.

Pick and Place vs Assembly Robot Infographic

libmatt.com

libmatt.com