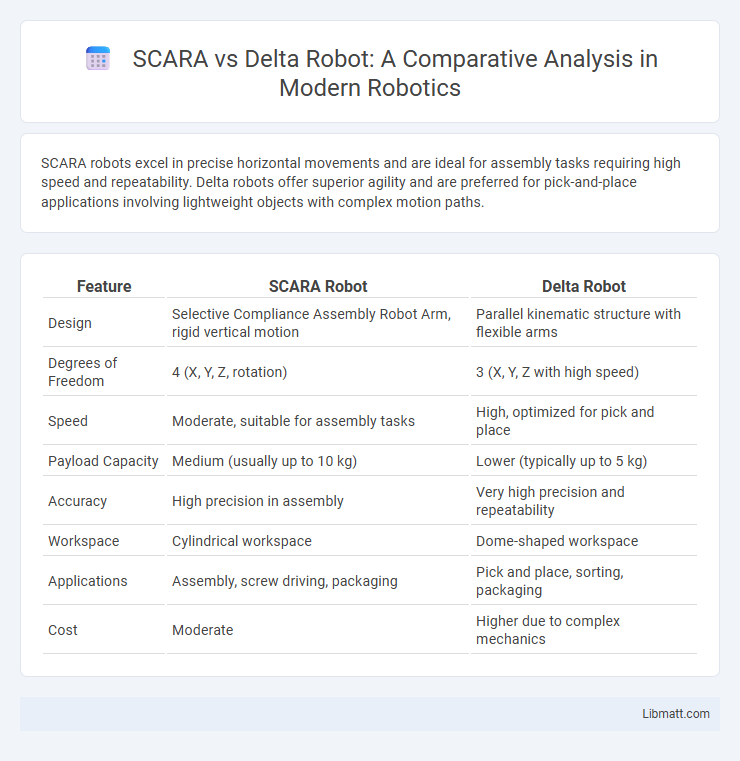

SCARA robots excel in precise horizontal movements and are ideal for assembly tasks requiring high speed and repeatability. Delta robots offer superior agility and are preferred for pick-and-place applications involving lightweight objects with complex motion paths.

Table of Comparison

| Feature | SCARA Robot | Delta Robot |

|---|---|---|

| Design | Selective Compliance Assembly Robot Arm, rigid vertical motion | Parallel kinematic structure with flexible arms |

| Degrees of Freedom | 4 (X, Y, Z, rotation) | 3 (X, Y, Z with high speed) |

| Speed | Moderate, suitable for assembly tasks | High, optimized for pick and place |

| Payload Capacity | Medium (usually up to 10 kg) | Lower (typically up to 5 kg) |

| Accuracy | High precision in assembly | Very high precision and repeatability |

| Workspace | Cylindrical workspace | Dome-shaped workspace |

| Applications | Assembly, screw driving, packaging | Pick and place, sorting, packaging |

| Cost | Moderate | Higher due to complex mechanics |

Introduction to SCARA and Delta Robots

SCARA robots feature a rigid arm with selective compliance in the horizontal plane, making them ideal for precise pick-and-place tasks and assembly operations. Delta robots possess a parallel-arm structure allowing high-speed, three-dimensional movement with exceptional accuracy, often used in packaging and sorting industries. Both types excel in automation but differ in kinematics and application suitability for various manufacturing environments.

Key Differences Between SCARA and Delta Robots

SCARA robots feature a rigid arm with rotational joints allowing precise horizontal movement ideal for assembly tasks, while Delta robots utilize a parallel arm structure for high-speed, three-dimensional picking and placing. SCARA excels in vertical precision and payload capacity, whereas Delta robots prioritize speed and agility with lighter loads. Understanding these differences helps you select the optimal robot for your specific industrial automation needs.

Design and Structure Comparison

SCARA robots feature a rigid, arm-like design with two parallel rotary joints allowing movements primarily in the horizontal plane, optimized for precise pick-and-place tasks. Delta robots possess a spider-like structure with three flexible arms connected to universal joints at the base, enabling high-speed, three-dimensional movements ideal for fast packaging and sorting. The SCARA's arm-based configuration excels in accuracy within confined spaces, while the Delta's parallel kinematic structure offers superior speed and agility over larger working areas.

Motion and Degrees of Freedom

SCARA robots offer four degrees of freedom with rigid vertical movement and precise horizontal positioning, making them ideal for tasks requiring accuracy and speed in planar motion. Delta robots feature three degrees of freedom with a parallel kinematic structure, enabling rapid and agile movements primarily in the vertical direction, suitable for high-speed pick-and-place operations. Your choice depends on whether you need the high-speed, flexible motion of a Delta robot or the precise, stable control of a SCARA robot.

Speed and Precision Capabilities

SCARA robots excel in precision due to their rigid arm structure and limited degrees of freedom, making them ideal for tasks requiring high repeatability and accurate positioning. Delta robots achieve superior speed through their lightweight, parallel-link design, enabling rapid acceleration and deceleration with minimal inertia. While SCARA robots offer better precision in assembly and pick-and-place operations, Delta robots dominate in high-speed applications such as packaging and sorting.

Typical Applications in Industry

SCARA robots excel in precise assembly tasks, pick-and-place operations, and packaging due to their horizontal articulation and high repeatability, making them ideal for electronics manufacturing and small parts assembly. Delta robots, with their high-speed parallel kinematics and lightweight arms, dominate industries requiring rapid and delicate handling, such as food packaging, pharmaceutical sorting, and lightweight material handling. Both robot types enhance production efficiency, with SCARA favoring medium payloads and complex movements, while Delta robots optimize speed for tasks demanding agility and gentle product handling.

Workspace and Footprint Considerations

SCARA robots typically offer a rectangular workspace with a moderate footprint, making them ideal for tasks requiring precision within a confined area such as assembly or pick-and-place operations. Delta robots provide a circular workspace with a minimal footprint due to their parallel arm design, excelling in high-speed, lightweight handling applications like packaging and sorting. Workspace shape and size directly influence robot selection based on task requirements and available floor space in manufacturing environments.

Cost-Effectiveness and ROI

SCARA robots generally offer higher cost-effectiveness for tasks requiring precise, repeatable horizontal movements due to their simpler design and lower maintenance expenses. Delta robots, while typically more expensive upfront, provide exceptional speed and flexibility, leading to faster cycle times and potentially quicker ROI in high-volume applications. Your choice depends on balancing initial investment against operational efficiency tailored to your production needs.

Selection Criteria: Which Robot to Choose?

Selecting between SCARA and Delta robots depends on your specific application needs, such as payload capacity, speed, and precision. SCARA robots excel in high-precision assembly and handling tasks with moderate payloads, while Delta robots outperform in high-speed pick-and-place operations with lighter loads. Your choice should consider the workspace layout, cycle time requirements, and the complexity of the tasks to ensure optimal automation efficiency.

Future Trends and Technological Advancements

SCARA robots are evolving with enhanced precision and payload capacity, driven by advancements in encoder technology and AI-based control systems, making them ideal for intricate assembly tasks. Delta robots are benefiting from improvements in lightweight materials and parallel kinematics algorithms, enabling faster cycle times and increased flexibility in packaging and sorting applications. Your choice between SCARA and Delta robots will depend on the specific speed, accuracy, and workspace requirements influenced by these future technological trends.

SCARA vs Delta Robot Infographic

libmatt.com

libmatt.com