A 6DOF (Degrees of Freedom) system allows movement along three translational axes (X, Y, Z) and three rotational axes (pitch, yaw, roll), while a 7DOF system adds an extra degree of freedom, often enabling more complex and flexible manipulation or articulation. Understanding the difference can help you select the right robotic arm or motion tracking device for tasks requiring precise control and increased adaptability.

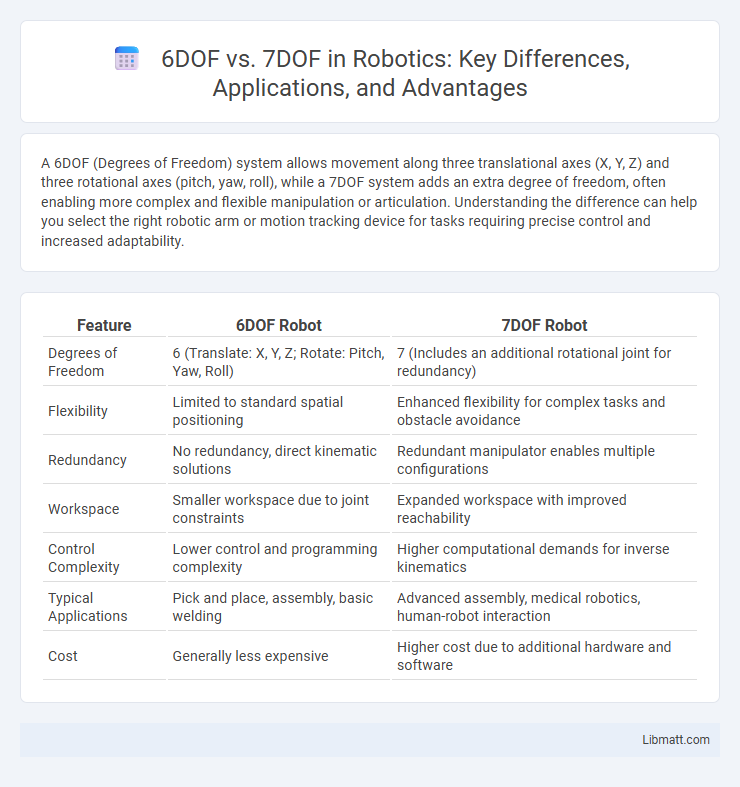

Table of Comparison

| Feature | 6DOF Robot | 7DOF Robot |

|---|---|---|

| Degrees of Freedom | 6 (Translate: X, Y, Z; Rotate: Pitch, Yaw, Roll) | 7 (Includes an additional rotational joint for redundancy) |

| Flexibility | Limited to standard spatial positioning | Enhanced flexibility for complex tasks and obstacle avoidance |

| Redundancy | No redundancy, direct kinematic solutions | Redundant manipulator enables multiple configurations |

| Workspace | Smaller workspace due to joint constraints | Expanded workspace with improved reachability |

| Control Complexity | Lower control and programming complexity | Higher computational demands for inverse kinematics |

| Typical Applications | Pick and place, assembly, basic welding | Advanced assembly, medical robotics, human-robot interaction |

| Cost | Generally less expensive | Higher cost due to additional hardware and software |

Understanding Degrees of Freedom: 6DOF vs 7DOF

6DOF refers to six degrees of freedom, allowing movement along the X, Y, and Z axes plus rotation around each of these axes: pitch, yaw, and roll. 7DOF introduces an additional degree, often a redundant joint or extension, enhancing flexibility and reach in robotic arms or VR motion tracking. Understanding these distinctions helps optimize your system's precision and adaptability based on the specific application needs.

Core Definitions: What Is 6DOF?

6DOF, or six degrees of freedom, represents movement in three-dimensional space through three translational axes (x, y, z) and three rotational axes (pitch, yaw, roll), enabling full spatial navigation and orientation. It is commonly used to describe the capabilities of motion tracking systems, robotics, and virtual reality devices that monitor both position and rotation of objects or users. In contrast, 7DOF typically extends 6DOF by incorporating an additional axis, often related to a unique joint or control parameter, allowing for more complex and precise manipulation beyond basic spatial movement.

Exploring 7DOF: Beyond Standard Movement

7DOF (seven degrees of freedom) enhances robotic arms or virtual avatars by adding an extra rotational axis compared to the standard 6DOF, allowing your movements to be more natural and precise in complex environments. This additional degree of freedom enables improved maneuverability, especially in tight spaces or intricate tasks, surpassing the conventional six degrees that cover position and orientation. Exploring 7DOF unlocks greater flexibility and realism for applications in robotics, animation, and VR, ultimately delivering superior control and interaction.

Key Differences Between 6DOF and 7DOF

6DOF (six degrees of freedom) provides movement along three translational axes (X, Y, Z) and three rotational axes (pitch, yaw, roll), enabling full spatial maneuverability for objects like robotic arms and VR devices. 7DOF includes an additional degree of freedom, often an extra rotational joint, which enhances flexibility, allowing for more complex and precise movements in tasks such as intricate robotic manipulation or human-like limb articulation. The key difference lies in the added versatility and redundancy of motion in 7DOF systems, offering greater capability in avoiding singularities and improving dexterity compared to 6DOF configurations.

Applications of 6DOF in Industry and Technology

6DOF (six degrees of freedom) enables precise movement and rotation along three perpendicular axes, making it essential for robotics, aerospace simulations, and virtual reality systems where accurate spatial positioning is crucial. Industries such as automotive manufacturing utilize 6DOF robotic arms to perform complex welding and assembly tasks with high precision and repeatability. In technology, 6DOF tracking enhances user experiences in VR and AR applications by allowing natural head and hand movements, improving immersion and interactivity.

Real-World Uses of 7DOF Systems

7DOF systems provide enhanced flexibility and precision in real-world applications such as robotic surgery, advanced prosthetics, and industrial automation, enabling complex movements and improved control. The additional degree of freedom allows for more natural and adaptive interactions in environments requiring intricate manipulations, surpassing the limitations of 6DOF models. This capability is critical in scenarios demanding high accuracy, such as minimally invasive procedures or multi-joint robotic arms in manufacturing.

Robotics and Automation: Choosing Between 6DOF and 7DOF

In robotics and automation, 6DOF (Degrees of Freedom) arms provide precise control over position and orientation, suitable for tasks like assembly and welding. 7DOF arms offer an extra degree of freedom, allowing for greater flexibility and maneuverability in complex environments, enhancing your robot's ability to avoid obstacles and reach difficult angles. Choosing between 6DOF and 7DOF depends on the task complexity, space constraints, and required dexterity in your automation system.

Advantages and Limitations of 6DOF

6DOF (six degrees of freedom) systems allow movement along three linear axes and rotation around three perpendicular axes, providing comprehensive spatial control ideal for applications like robotics and VR. Their advantages include simpler mechanics, lower cost, and easier control compared to 7DOF systems, which add an extra degree of freedom to enable more complex manipulations. However, 6DOF limitations arise when tasks require redundancy or flexibility in maneuvering, as the inability to adjust the additional joint can reduce precision and adaptability in intricate operations.

7DOF: Benefits and Challenges

7DOF robotic arms offer enhanced flexibility and dexterity by adding an extra degree of freedom compared to 6DOF systems, allowing for more complex and natural movements in confined spaces. This additional joint improves reachability and maneuverability, making 7DOF ideal for tasks requiring intricate positioning and orientation adjustments. However, the increased complexity presents challenges in terms of control algorithms, calibration accuracy, and computational demands, requiring advanced sensor integration and sophisticated motion planning strategies.

Future Trends: 6DOF vs 7DOF in Innovation

Future trends in robotics and automation show a growing emphasis on 7DOF systems, which offer enhanced flexibility and range of motion compared to traditional 6DOF configurations. The additional degree of freedom enables more complex and precise tasks, making 7DOF increasingly vital in advanced manufacturing, medical robotics, and human-robot interaction. Investing in 7DOF technology can future-proof your projects by aligning with the next wave of innovations in robotic dexterity and control.

6DOF vs 7DOF Infographic

libmatt.com

libmatt.com