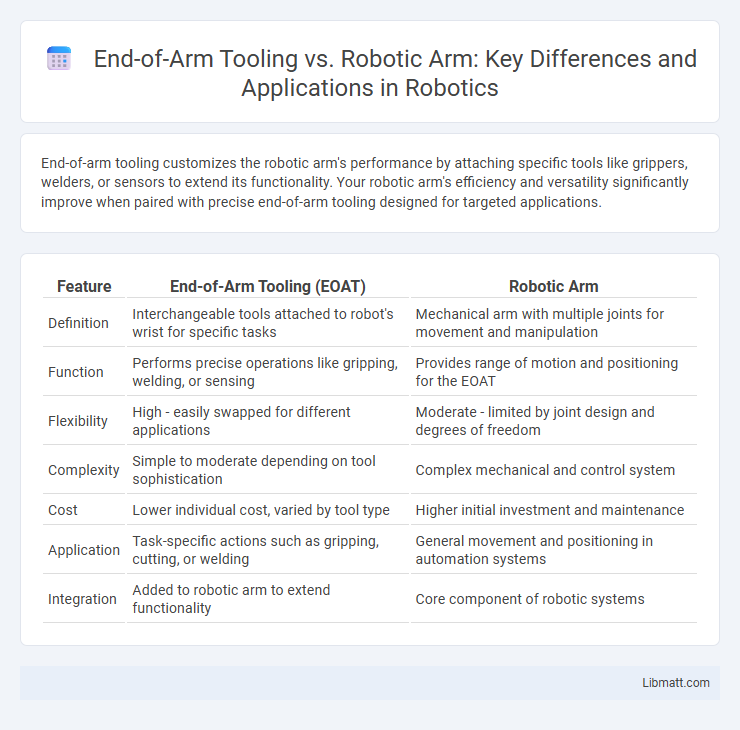

End-of-arm tooling customizes the robotic arm's performance by attaching specific tools like grippers, welders, or sensors to extend its functionality. Your robotic arm's efficiency and versatility significantly improve when paired with precise end-of-arm tooling designed for targeted applications.

Table of Comparison

| Feature | End-of-Arm Tooling (EOAT) | Robotic Arm |

|---|---|---|

| Definition | Interchangeable tools attached to robot's wrist for specific tasks | Mechanical arm with multiple joints for movement and manipulation |

| Function | Performs precise operations like gripping, welding, or sensing | Provides range of motion and positioning for the EOAT |

| Flexibility | High - easily swapped for different applications | Moderate - limited by joint design and degrees of freedom |

| Complexity | Simple to moderate depending on tool sophistication | Complex mechanical and control system |

| Cost | Lower individual cost, varied by tool type | Higher initial investment and maintenance |

| Application | Task-specific actions such as gripping, cutting, or welding | General movement and positioning in automation systems |

| Integration | Added to robotic arm to extend functionality | Core component of robotic systems |

Introduction to End-of-Arm Tooling and Robotic Arms

End-of-arm tooling (EOAT) refers to the specialized devices attached to the end of robotic arms that enable precise interaction with objects, including grippers, welders, and suction cups. Robotic arms are programmable mechanical structures designed to replicate human arm movements for tasks like assembly, welding, and packaging. Your automation system's efficiency depends heavily on selecting the right combination of robotic arms and end-of-arm tooling tailored to specific industrial applications.

Core Differences Between End-of-Arm Tooling and Robotic Arms

End-of-arm tooling (EOAT) refers to the specialized devices attached to the end of a robotic arm designed for specific tasks like gripping, welding, or painting, whereas robotic arms are the mechanical structures that provide movement and positioning capabilities. EOAT is task-specific and interchangeable, enabling robots to perform diverse functions by swapping the tooling as needed. Robotic arms provide the fundamental degrees of freedom and motion control, while EOAT directly interacts with the workpiece to execute precise operations.

Key Components of Robotic Arms

Robotic arms consist of key components including actuators, sensors, controllers, and end-effectors, which work together to enable precise and versatile movements. End-of-arm tooling serves as the customizable interface attached to the robotic arm, designed to interact with objects based on specific tasks like gripping, welding, or assembly. Understanding the synergy between your robotic arm's components and its end-of-arm tooling maximizes operational efficiency and adaptability in automated processes.

Types of End-of-Arm Tooling

End-of-arm tooling (EOAT) encompasses a variety of specialized devices attached to the end of robotic arms, including grippers, suction cups, welding torches, and sensors designed for specific industrial tasks. These tools enable precise handling, manipulation, and processing of materials in automation settings, enhancing your robot's versatility and efficiency. Selecting the appropriate EOAT type, such as pneumatic grippers for delicate objects or magnetic grippers for metal components, directly impacts the performance and adaptability of robotic systems.

Functionality and Application Comparison

End-of-arm tooling (EOAT) refers to specialized devices attached to the robotic arm's end to perform specific tasks like gripping, welding, or painting, enhancing the robot's functionality and precision. The robotic arm itself provides the primary movement and positioning capabilities, enabling EOAT to reach and manipulate objects in complex environments. Your choice between EOAT and robotic arms depends on application needs; EOAT customizes functionality for tasks, while robotic arms offer versatile motion essential for automation in manufacturing, assembly, and material handling.

Flexibility and Customization Options

End-of-arm tooling (EOAT) offers superior flexibility and customization options by allowing you to easily switch grippers, sensors, or specialized end-effectors tailored to specific tasks, enhancing adaptability for varied applications. Robotic arms provide a foundation with precise movements and programmable functions but rely on EOAT for task-specific versatility and fine control. Your ability to optimize automation hinges on selecting EOAT that complements the robotic arm's capabilities for maximum efficiency and customization.

Cost Considerations and ROI

End-of-arm tooling (EOAT) typically entails lower initial costs compared to investing in a full robotic arm, making it a cost-effective option for enhancing existing automation systems. EOAT enables quicker deployment and flexibility in handling various tasks, which can accelerate return on investment (ROI) by minimizing downtime and maximizing productivity. In contrast, robotic arms require higher capital expenditure but offer broader operational capabilities and greater long-term ROI potential in complex automation environments.

Integration and Compatibility Challenges

End-of-arm tooling (EOAT) requires precise integration with robotic arms to ensure seamless operation, yet compatibility challenges arise due to varied interface standards and load capacities. Customizing EOAT for specific robotic arm models often demands extensive calibration and software adjustments to maintain accuracy and efficiency. Your automation setup benefits significantly by selecting EOAT designed with standardized mounting systems and flexible communication protocols to reduce integration complexity.

Industry-Specific Use Cases

End-of-arm tooling (EOAT) is customized for precise tasks like welding in automotive manufacturing, packaging in food production, and assembly in electronics, enhancing efficiency by adapting to specific industry requirements. Robotic arms, equipped with versatile EOAT, perform complex operations including material handling in logistics, palletizing in warehousing, and quality inspection in pharmaceuticals, enabling automation across diverse sectors. Integration of EOAT with robotic arms drives industry-specific solutions by enabling tasks that range from delicate manipulation in medical device production to heavy lifting in metal fabrication.

Future Trends in End-of-Arm Tooling and Robotic Arms

Future trends in end-of-arm tooling emphasize increased modularity, enabling rapid adaptation to diverse tasks and industries, while advancements in lightweight composite materials enhance tool durability and reduce robotic arm payload. Simultaneously, robotic arms are evolving with integrated AI and machine learning algorithms that improve precision, autonomous decision-making, and adaptability in complex environments. Collaborative robots (cobots) equipped with advanced sensors and safer end effectors highlight the shift toward human-robot interaction in industrial automation.

End-of-arm Tooling vs Robotic Arm Infographic

libmatt.com

libmatt.com