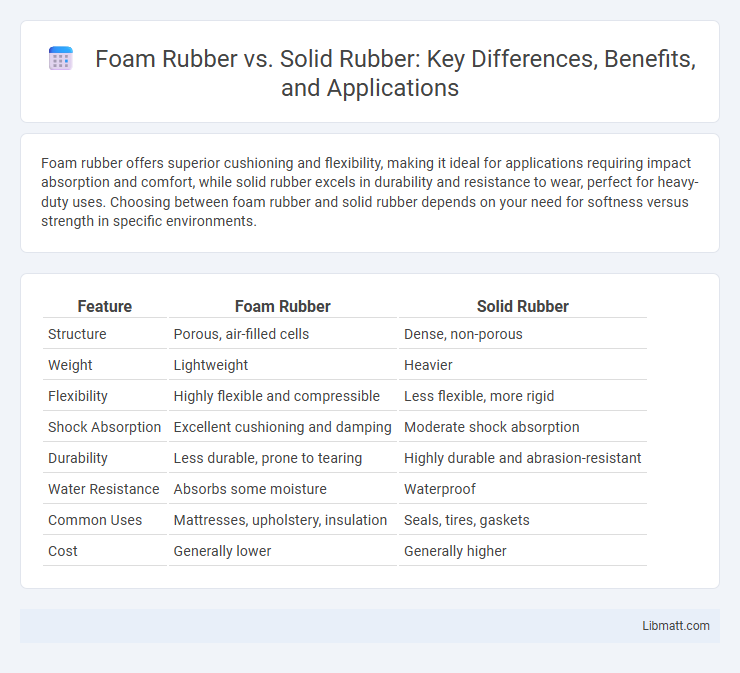

Foam rubber offers superior cushioning and flexibility, making it ideal for applications requiring impact absorption and comfort, while solid rubber excels in durability and resistance to wear, perfect for heavy-duty uses. Choosing between foam rubber and solid rubber depends on your need for softness versus strength in specific environments.

Table of Comparison

| Feature | Foam Rubber | Solid Rubber |

|---|---|---|

| Structure | Porous, air-filled cells | Dense, non-porous |

| Weight | Lightweight | Heavier |

| Flexibility | Highly flexible and compressible | Less flexible, more rigid |

| Shock Absorption | Excellent cushioning and damping | Moderate shock absorption |

| Durability | Less durable, prone to tearing | Highly durable and abrasion-resistant |

| Water Resistance | Absorbs some moisture | Waterproof |

| Common Uses | Mattresses, upholstery, insulation | Seals, tires, gaskets |

| Cost | Generally lower | Generally higher |

Introduction to Foam Rubber and Solid Rubber

Foam rubber is a lightweight, porous material characterized by its cellular structure, providing excellent cushioning and flexibility, ideal for applications in upholstery, insulation, and padding. Solid rubber is a dense, non-porous elastomer known for its durability, resistance to wear, and high tensile strength, commonly used in tires, seals, and industrial components. Understanding the distinct physical properties and applications of foam rubber and solid rubber is essential for selecting the appropriate material based on performance requirements.

Composition and Manufacturing Processes

Foam rubber consists of a cellular structure created by introducing gas bubbles during vulcanization, resulting in a lightweight, flexible material with open or closed cells, while solid rubber is a dense, homogeneous elastomer composed of polymer chains without air pockets. Manufacturing foam rubber involves incorporating blowing agents or whipping air into liquid rubber compounds before curing, whereas solid rubber is produced through standard vulcanization or curing processes that enhance elasticity and durability. Understanding these differences helps you choose the right material based on resilience, cushioning, and weight requirements for your application.

Physical Properties Comparison

Foam rubber exhibits a lightweight, porous structure that offers excellent cushioning and flexibility, making it ideal for applications requiring shock absorption and insulation. In contrast, solid rubber boasts higher density and durability, providing superior resistance to abrasion, impact, and environmental factors such as oil and chemicals. Your choice between foam rubber and solid rubber depends on whether you prioritize compressibility and softness or strength and longevity in physical performance.

Weight and Density Differences

Foam rubber is significantly lighter than solid rubber due to its porous structure, which reduces its density and enhances cushioning properties. Solid rubber's higher density results in greater weight and durability, making it ideal for applications requiring robustness and impact resistance. The difference in density directly influences product performance, with foam rubber preferred for lightweight, flexible uses and solid rubber chosen for strength and longevity.

Durability and Lifespan

Solid rubber offers superior durability and a longer lifespan compared to foam rubber due to its dense molecular structure, making it ideal for high-impact and heavy-use applications. Foam rubber, while softer and more flexible, tends to degrade faster under consistent pressure and environmental exposure, leading to a shorter functional lifespan. When choosing materials, consider your specific durability needs and expected usage to ensure Your product performs optimally over time.

Cushioning and Comfort Levels

Foam rubber offers superior cushioning and absorbs impacts effectively, making it ideal for products requiring softness and comfort, such as mattresses and shoes. Solid rubber provides firmer support and durability but lacks the plush feel of foam, which may result in less comfort during prolonged use. Your choice depends on whether you prioritize soft cushioning or resilient support in applications like footwear or seating.

Common Applications and Uses

Foam rubber excels in cushioning and insulation applications due to its lightweight, porous structure, making it ideal for furniture padding, mattresses, and soundproofing materials. Solid rubber, characterized by its density and durability, is commonly used in heavy-duty products like tires, conveyor belts, and industrial gaskets. Both materials serve crucial roles in automotive, manufacturing, and consumer goods industries, tailored to specific performance needs based on flexibility and resilience.

Cost and Availability

Foam rubber typically costs less than solid rubber due to its lower density and simpler manufacturing process, making it more budget-friendly for large-scale applications. Solid rubber, while more expensive, offers greater durability and resistance, which can justify the higher price for long-term use. Foam rubber is widely available in various grades for cushioning purposes, whereas solid rubber is commonly found in industrial and heavy-duty products, slightly limiting its availability for casual consumers.

Environmental Impact and Recyclability

Foam rubber typically has a higher environmental impact due to its production involving petroleum-based chemicals and limited biodegradability, whereas solid rubber, especially natural rubber, is more sustainable and biodegradable. Solid rubber products generally offer better recyclability as they can be reprocessed into new rubber goods, unlike foam rubber which often ends up in landfills because of its complex polymer structure. Choosing solid rubber over foam rubber reduces waste and supports circular economy initiatives in the rubber industry.

Choosing the Right Type for Your Needs

Foam rubber offers excellent cushioning and shock absorption, making it ideal for applications requiring lightweight, flexible padding such as upholstery and mattresses. Solid rubber provides superior durability, resilience, and resistance to abrasion, suitable for heavy-duty uses like tires, seals, and industrial gaskets. Selecting between foam and solid rubber depends on factors like load-bearing requirements, environmental exposure, and desired comfort levels.

Foam Rubber vs Solid Rubber Infographic

libmatt.com

libmatt.com