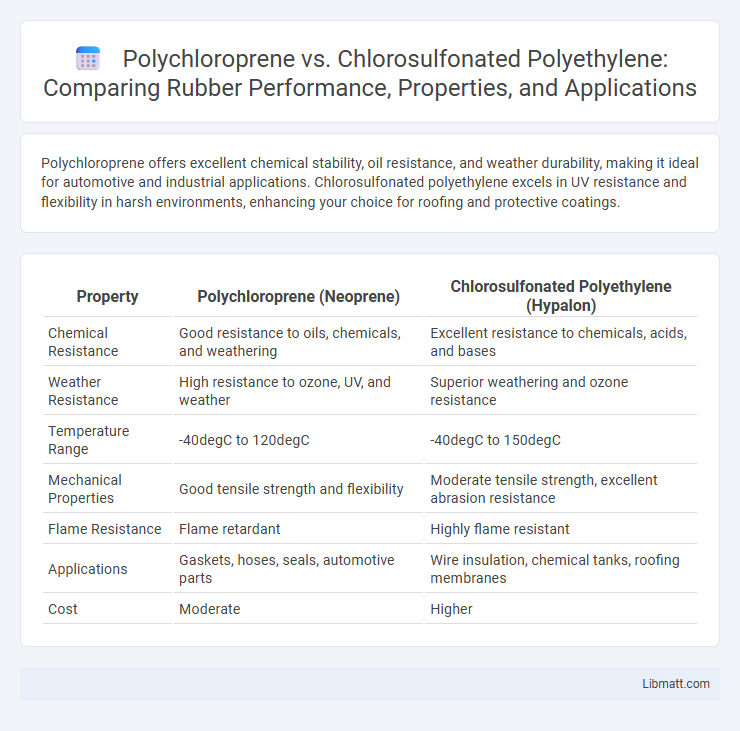

Polychloroprene offers excellent chemical stability, oil resistance, and weather durability, making it ideal for automotive and industrial applications. Chlorosulfonated polyethylene excels in UV resistance and flexibility in harsh environments, enhancing your choice for roofing and protective coatings.

Table of Comparison

| Property | Polychloroprene (Neoprene) | Chlorosulfonated Polyethylene (Hypalon) |

|---|---|---|

| Chemical Resistance | Good resistance to oils, chemicals, and weathering | Excellent resistance to chemicals, acids, and bases |

| Weather Resistance | High resistance to ozone, UV, and weather | Superior weathering and ozone resistance |

| Temperature Range | -40degC to 120degC | -40degC to 150degC |

| Mechanical Properties | Good tensile strength and flexibility | Moderate tensile strength, excellent abrasion resistance |

| Flame Resistance | Flame retardant | Highly flame resistant |

| Applications | Gaskets, hoses, seals, automotive parts | Wire insulation, chemical tanks, roofing membranes |

| Cost | Moderate | Higher |

Introduction to Polychloroprene and Chlorosulfonated Polyethylene

Polychloroprene, commonly known as neoprene, is a synthetic rubber renowned for its excellent chemical stability, weather resistance, and flexibility, making it ideal for automotive, industrial, and consumer applications. Chlorosulfonated polyethylene (CSPE) offers superior resistance to ozone, UV rays, and harsh chemicals, which enhances its durability in roofing, wire insulation, and protective coatings. Understanding the properties of these two elastomers helps you select the right material for specific environmental and performance requirements.

Chemical Structure Comparison

Polychloroprene features a repeating unit of chloroprene with both chlorine atoms and double bonds that provide excellent chemical resistance and flexibility, while chlorosulfonated polyethylene (CSPE) consists of saturated polyethylene chains modified by chlorosulfonic acid, incorporating chlorine and sulfonyl chloride groups that enhance weather and chemical resistance. The presence of sulfur-containing groups in CSPE imparts unique cross-linking properties absent in polychloroprene's polymer matrix. Your choice depends on whether you require the unsaturated backbone and elastomeric properties of polychloroprene or the enhanced durability and resistance of CSPE's chemically modified polyethylene.

Manufacturing Processes

Polychloroprene is produced through free radical emulsion polymerization of chloroprene monomers, resulting in a synthetic rubber with strong tensile strength and chemical resistance. Chlorosulfonated Polyethylene is manufactured by chlorosulfonation of polyethylene, incorporating chlorine and sulfonyl chloride groups into the polymer chain to enhance weather and chemical durability. The differences in polymerization techniques and chemical modifications directly affect their physical properties and industrial applications.

Physical and Mechanical Properties

Polychloroprene exhibits excellent tensile strength, flexibility, and good resistance to abrasion and weathering, making it suitable for dynamic applications requiring durability and elasticity. Chlorosulfonated polyethylene offers superior chemical and UV resistance with moderate tensile strength and enhanced resistance to ozone and outdoor exposure. The choice between these materials depends on the specific mechanical load and environmental stress conditions, with Polychloroprene favored for dynamic wear and Chlorosulfonated Polyethylene excelling in harsh chemical and weather conditions.

Resistance to Chemicals and Weathering

Polychloroprene exhibits excellent resistance to oil, chemicals, and ozone, making it highly durable in harsh chemical environments. Chlorosulfonated polyethylene offers superior resistance to weathering, UV radiation, and oxidation, maintaining elasticity and strength in outdoor applications. Both polymers provide robust chemical resistance, but chlorosulfonated polyethylene is preferred for long-term exposure to sunlight and extreme weather conditions.

Heat and Flame Resistance

Polychloroprene exhibits superior heat and flame resistance due to its inherent chlorinated polymer structure, maintaining stability at temperatures up to 120degC and self-extinguishing properties that reduce flame spread. Chlorosulfonated Polyethylene offers moderate heat resistance, tolerating continuous use up to 90degC, with enhanced flame retardancy provided by its sulfonyl and chlorine content but generally less effective compared to Polychloroprene. Both materials are widely used in applications requiring durability under thermal stress, but Polychloroprene is preferred where higher heat resilience and flame retardance are critical.

Typical Applications in Industry

Polychloroprene, commonly known as neoprene, is widely used in automotive parts, industrial gaskets, adhesives, and protective wetsuits due to its excellent chemical stability and resistance to oils and ozone. Chlorosulfonated polyethylene (CSPE) finds typical applications in roofing membranes, protective coatings, and cable jacketing because of its superior weather resistance and flexibility. Both materials are favored in industries requiring durable elastomers but are selected based on specific environmental resistance and mechanical property needs.

Environmental Impact and Sustainability

Polychloroprene (neoprene) and chlorosulfonated polyethylene (CSPE) differ significantly in environmental impact and sustainability, with CSPE generally considered more eco-friendly due to its resistance to weathering and lower toxic emissions during production. Polychloroprene production involves chlorinated compounds that can release harmful pollutants and are less biodegradable, whereas CSPE offers improved recyclability and longer lifecycle performance, reducing waste. Your choice between these materials should weigh long-term environmental benefits and regulatory compliance for sustainable applications.

Cost and Availability

Polychloroprene typically incurs higher costs due to its superior chemical resistance and durability, making it a preferred choice for specialized applications. Chlorosulfonated polyethylene offers more cost-effective solutions with easier availability, especially in bulk quantities for general industrial use. Your selection between these materials should balance budget constraints with performance requirements and supply chain accessibility.

Choosing the Right Material: Key Considerations

Polychloroprene offers excellent chemical stability, weather resistance, and flexibility, making it ideal for applications requiring durability in harsh environments. Chlorosulfonated polyethylene excels in UV resistance, ozone resistance, and resistance to oils and acids, making it suitable for outdoor seals and gaskets exposed to aggressive conditions. When choosing between Polychloroprene and Chlorosulfonated Polyethylene, consider factors like exposure to chemicals, temperature ranges, mechanical stress, and environmental conditions to ensure optimal performance and longevity.

Polychloroprene vs Chlorosulfonated Polyethylene Infographic

libmatt.com

libmatt.com