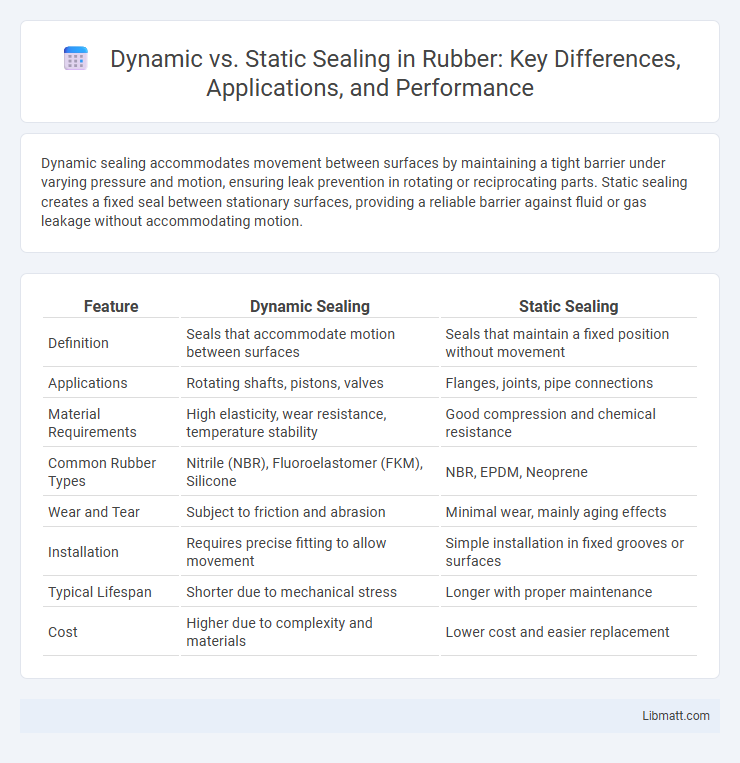

Dynamic sealing accommodates movement between surfaces by maintaining a tight barrier under varying pressure and motion, ensuring leak prevention in rotating or reciprocating parts. Static sealing creates a fixed seal between stationary surfaces, providing a reliable barrier against fluid or gas leakage without accommodating motion.

Table of Comparison

| Feature | Dynamic Sealing | Static Sealing |

|---|---|---|

| Definition | Seals that accommodate motion between surfaces | Seals that maintain a fixed position without movement |

| Applications | Rotating shafts, pistons, valves | Flanges, joints, pipe connections |

| Material Requirements | High elasticity, wear resistance, temperature stability | Good compression and chemical resistance |

| Common Rubber Types | Nitrile (NBR), Fluoroelastomer (FKM), Silicone | NBR, EPDM, Neoprene |

| Wear and Tear | Subject to friction and abrasion | Minimal wear, mainly aging effects |

| Installation | Requires precise fitting to allow movement | Simple installation in fixed grooves or surfaces |

| Typical Lifespan | Shorter due to mechanical stress | Longer with proper maintenance |

| Cost | Higher due to complexity and materials | Lower cost and easier replacement |

Introduction to Sealing Technologies

Sealing technologies are essential for preventing fluid or gas leakage in various industrial applications, with dynamic and static sealing being the two primary categories. Dynamic sealing accommodates motion between surfaces, such as rotating shafts, using components like O-rings or lip seals designed to maintain integrity under movement. Static sealing, in contrast, involves sealing non-moving parts using gaskets or adhesives to create a tight barrier, ensuring your equipment operates efficiently without leaks.

What is Dynamic Sealing?

Dynamic sealing refers to the process of creating a seal between two surfaces that move relative to each other, such as rotating shafts or sliding components, to prevent leakage of fluids or contaminants. These seals must accommodate motion while maintaining tightness under varying pressure, temperature, and speed conditions. Your choice of dynamic sealing affects equipment performance, reliability, and maintenance intervals in applications like engines, pumps, and hydraulic systems.

What is Static Sealing?

Static sealing refers to the process of creating a leak-proof barrier between two stationary surfaces, preventing fluid or gas leakage under pressure. This sealing method typically employs gaskets, O-rings, or sealants positioned where no relative motion occurs between sealed parts. Static seals are essential in applications such as flanges, pipe joints, and engine components where components remain fixed during operation.

Key Differences Between Dynamic and Static Seals

Dynamic seals accommodate motion between surfaces by maintaining a sealing interface despite relative movement, while static seals create a barrier between stationary components to prevent leakage. Key differences include design complexity, material selection, and wear resistance, with dynamic seals requiring flexibility and durability under friction, whereas static seals emphasize deformation and compression to maintain tightness. Your choice depends on operational conditions, such as pressure, temperature, and movement type, ensuring optimal performance and longevity.

Applications of Dynamic Seals

Dynamic seals are essential in applications involving reciprocating, rotary, or oscillating motion, such as hydraulic cylinders, pumps, compressors, and gearboxes, where they prevent fluid leakage while accommodating movement. These seals maintain efficiency and longevity in automotive engines, industrial machinery, and aerospace systems by withstanding pressure, temperature, and friction. Optimizing your equipment with precisely engineered dynamic seals enhances performance and reduces maintenance costs in demanding operational environments.

Applications of Static Seals

Static seals are essential in applications where components remain stationary, such as flanged joints, pipe connectors, and valve covers, preventing fluid or gas leakage under high pressure or extreme temperature conditions. These seals are commonly used in hydraulic systems, automotive engines, and industrial machinery to maintain airtight and watertight integrity. Materials like rubber, PTFE, and metal gaskets provide reliable performance in static sealing tasks, ensuring durability and resistance to chemical corrosion.

Material Selection for Dynamic and Static Seals

Material selection for dynamic seals prioritizes flexibility and wear resistance, often using elastomers like nitrile, fluorocarbon, or silicone to accommodate movement and prevent leakage under varying pressures. Static seals require materials with excellent compression set resistance and chemical stability, such as PTFE, graphite, or metal gaskets, to maintain tight sealing without deformation. Choosing the appropriate material for your application enhances seal longevity and performance by addressing dynamic friction or static pressure conditions effectively.

Performance Factors: Leakage, Durability, and Maintenance

Dynamic sealing typically experiences higher leakage rates due to continuous movement causing wear, while static sealing offers superior leakage prevention under stable conditions. Durability in dynamic seals depends on material flexibility and resistance to friction, whereas static seals boast longer lifespan with less mechanical stress. Your maintenance needs increase with dynamic seals, requiring frequent inspections and replacements compared to the relatively low upkeep of static seals.

Challenges and Solutions in Sealing Systems

Dynamic sealing systems face challenges such as friction, wear, and leakage due to continuous motion between sealing surfaces, which can compromise system integrity and efficiency. Solutions include using advanced materials like PTFE or elastomers with high wear resistance, precision-engineered designs to maintain tight tolerances, and lubrication strategies to reduce friction and heat buildup. Your sealing system's performance can be optimized by selecting the appropriate dynamic or static sealing approach based on operational conditions and maintenance requirements.

Choosing the Right Seal for Your Application

Selecting the right seal for your application depends on whether the sealing surfaces move relative to each other (dynamic) or remain stationary (static). Dynamic seals, such as rotary shaft seals and piston rings, are designed to accommodate motion while maintaining a tight barrier, whereas static seals like gaskets and O-rings provide leak prevention between fixed surfaces. Understanding operational conditions such as pressure, temperature, and movement speed helps you optimize seal performance and durability.

Dynamic vs Static Sealing Infographic

libmatt.com

libmatt.com