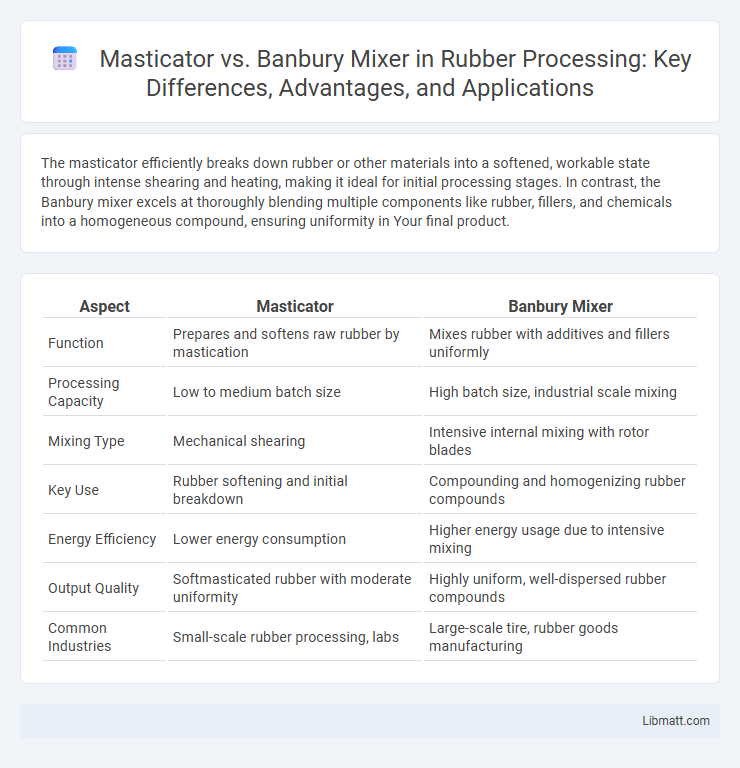

The masticator efficiently breaks down rubber or other materials into a softened, workable state through intense shearing and heating, making it ideal for initial processing stages. In contrast, the Banbury mixer excels at thoroughly blending multiple components like rubber, fillers, and chemicals into a homogeneous compound, ensuring uniformity in Your final product.

Table of Comparison

| Aspect | Masticator | Banbury Mixer |

|---|---|---|

| Function | Prepares and softens raw rubber by mastication | Mixes rubber with additives and fillers uniformly |

| Processing Capacity | Low to medium batch size | High batch size, industrial scale mixing |

| Mixing Type | Mechanical shearing | Intensive internal mixing with rotor blades |

| Key Use | Rubber softening and initial breakdown | Compounding and homogenizing rubber compounds |

| Energy Efficiency | Lower energy consumption | Higher energy usage due to intensive mixing |

| Output Quality | Softmasticated rubber with moderate uniformity | Highly uniform, well-dispersed rubber compounds |

| Common Industries | Small-scale rubber processing, labs | Large-scale tire, rubber goods manufacturing |

Introduction to Masticator and Banbury Mixer

Masticators and Banbury mixers are essential machines used in the rubber and polymer processing industries for mixing raw materials effectively. The Masticator primarily serves to break down rubber into a softer, more workable mass by shearing and warming, while the Banbury mixer performs high-intensity mixing of various compounds, ensuring uniform dispersion of fillers and additives. Your choice between these machines depends on the scale and specific requirements of your production process, with Banbury mixers often preferred for larger batches and complex formulations.

Overview of Mixing Technologies

Masticator and Banbury Mixer represent two advanced mixing technologies widely used in the rubber and polymer industries, each designed to enhance material uniformity and processing efficiency. The Masticator excels in pre-mixing and reclaiming rubber by applying intense shear and heat, while the Banbury Mixer utilizes powerful rotors within a closed chamber to achieve rapid, homogeneous blending of compounds at larger scales. Your choice depends on the specific application requirements, such as batch size, energy input, and material characteristics, optimizing production quality and consistency.

Key Components of a Masticator

A masticator features a heavy-duty mixing chamber containing two intermeshing rotors that shear and soften rubber compounds efficiently. Equipped with a robust hydraulic ram or ram-style system, it compresses material to improve mixing consistency and reduce processing time. The machine's temperature control system ensures optimal heat generation for polymer plasticization during the mastication process.

Key Components of a Banbury Mixer

A Banbury mixer features a robust rotors assembly consisting of two intermeshing rotors that provide efficient shear and mixing action for rubber and plastic compounds. The mixer includes a discharge door for rapid unloading of mixed materials and a powerful motor to maintain consistent torque and speed. Temperature control systems such as water jackets and cooling channels are integrated into the mixing chamber to prevent overheating and ensure optimal mixing conditions.

Mixing Mechanism and Process Differences

Masticator and Banbury mixers differ primarily in their mixing mechanisms and processes, with the masticator using a mechanical shearing and breaking action to soften and prepare rubber or similar materials, while the Banbury mixer employs a powerful internal mixing chamber with rotating rotors to achieve thorough blending of polymers, fillers, and additives. The Banbury mixer enables higher temperature and pressure control, resulting in more uniform dispersion and faster processing, suited for large-scale production. Your choice depends on the specific mixing intensity and material compatibility required for your application.

Applications in Industrial Settings

Masticators are primarily used in smaller-scale industrial settings for pre-mixing and breaking down raw rubber or plastic materials, ideal for compounding and recycling applications. Banbury mixers, featuring powerful blades and high shear mixing capabilities, excel in large-scale industrial production, effectively blending polymers, fillers, and additives in the tire, rubber, and plastic industries. Understanding your production volume and material requirements helps determine whether a masticator or Banbury mixer best optimizes your manufacturing process.

Advantages of Masticator Mixers

Masticator mixers offer superior mixing efficiency for rubber compounds, ensuring uniform dispersion of fillers and additives through intense shearing action. Their robust design enables continuous processing with reduced cycle times, enhancing productivity in rubber manufacturing. Enhanced temperature control in masticator mixers prevents material degradation, resulting in higher-quality end products compared to Banbury mixers.

Advantages of Banbury Mixers

Banbury Mixers offer superior mixing efficiency and consistency compared to Masticators, making them ideal for large-scale industrial rubber and plastic processing. Their ability to deliver precise temperature control and high shear force ensures homogeneous compound dispersion, enhancing product quality and reducing production time. You can achieve improved operational reliability and lower maintenance costs with Banbury Mixers, optimizing your manufacturing process.

Comparative Performance Analysis

Masticators and Banbury mixers differ significantly in mixing efficiency and energy consumption, with the Banbury mixer excelling in high-speed, high-shear applications ideal for rubber and polymer compounding. The Masticator, though simpler and more cost-effective, offers lower mixing precision and throughput, making it suitable for preliminary mastication and blending tasks. Your choice should consider the specific processing requirements, with the Banbury mixer favored for demanding formulations that require uniform dispersion and rapid mixing.

Choosing the Right Mixer for Your Needs

Selecting the right mixer depends on the specific requirements of your mixing process and material characteristics. Masticators excel in intensive shearing and are ideal for rubber compounding, offering better dispersion and consistent mixing of high-viscosity materials. Banbury mixers provide efficient batch mixing with rapid heat generation, suitable for large-scale production and materials requiring thorough blending of multiple components.

Masticator vs Banbury Mixer Infographic

libmatt.com

libmatt.com