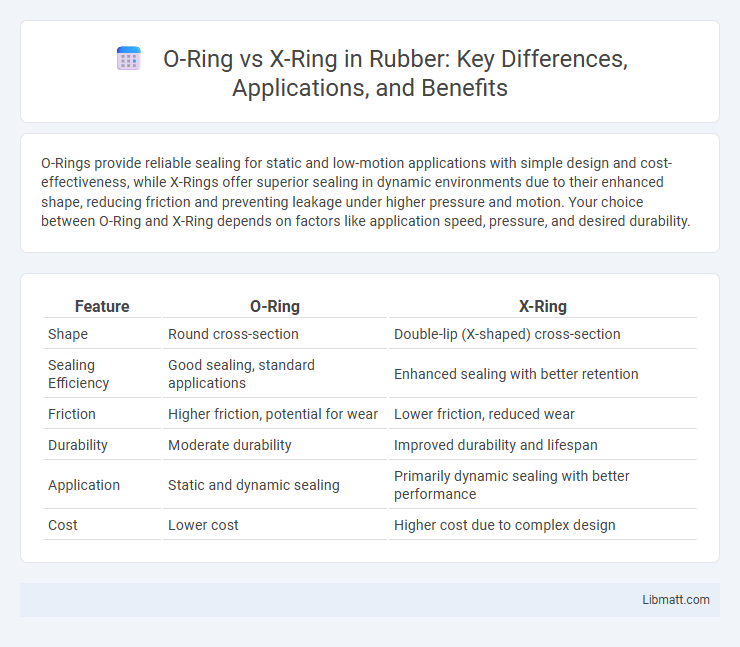

O-Rings provide reliable sealing for static and low-motion applications with simple design and cost-effectiveness, while X-Rings offer superior sealing in dynamic environments due to their enhanced shape, reducing friction and preventing leakage under higher pressure and motion. Your choice between O-Ring and X-Ring depends on factors like application speed, pressure, and desired durability.

Table of Comparison

| Feature | O-Ring | X-Ring |

|---|---|---|

| Shape | Round cross-section | Double-lip (X-shaped) cross-section |

| Sealing Efficiency | Good sealing, standard applications | Enhanced sealing with better retention |

| Friction | Higher friction, potential for wear | Lower friction, reduced wear |

| Durability | Moderate durability | Improved durability and lifespan |

| Application | Static and dynamic sealing | Primarily dynamic sealing with better performance |

| Cost | Lower cost | Higher cost due to complex design |

Introduction to Sealing Rings

Sealing rings such as O-rings and X-rings serve crucial roles in preventing fluid and gas leaks in mechanical systems. O-rings are circular, offering simple installation and effective sealing for static and dynamic applications. X-rings feature a unique cross-sectional shape that reduces friction and improves sealing performance under high pressure and motion conditions.

What is an O-Ring?

An O-Ring is a circular sealing element made of elastomer, designed to fit into a groove and compress between two or more parts, preventing the passage of liquids or gases. It is commonly used in hydraulic and pneumatic systems due to its simple design and reliable sealing performance. Your equipment benefits from O-Rings by ensuring efficient containment under varying pressure and temperature conditions.

What is an X-Ring?

An X-Ring is a type of seal designed with a unique cross-sectional shape resembling the letter "X," which provides superior sealing performance compared to traditional O-Rings. The X-shaped profile offers enhanced flexibility, reduced friction, and better groove filling, making it ideal for high-pressure or dynamic applications. Your equipment benefits from the improved durability and leak prevention that X-Rings deliver in demanding environments.

Material Comparison

O-Rings are commonly made from materials such as nitrile, silicone, and Viton, offering reliable sealing capabilities in standard applications. X-Rings, often manufactured from similar elastomers, provide enhanced durability and reduced friction due to their unique cross-section shape. Your choice between these seals should consider material compatibility with fluids, temperature ranges, and wear resistance to ensure optimal performance.

Sealing Efficiency: O-Ring vs X-Ring

X-Rings provide superior sealing efficiency compared to traditional O-Rings due to their unique cross-sectional design, which creates multiple sealing surfaces and reduces friction. The X-Ring's dual sealing lips maintain better contact with mating surfaces, enhancing performance in dynamic applications and minimizing leakage. O-Rings typically offer a single sealing surface, making them less effective in high-pressure or high-stress environments where X-Rings excel.

Durability and Longevity

O-Rings and X-Rings differ significantly in durability and longevity, with X-Rings generally offering superior performance due to their unique shape, which provides better sealing and reduced friction. The design of X-Rings helps maintain lubrication longer and reduces wear, making them ideal for high-stress or high-temperature environments. Choosing X-Rings for your application can extend the lifespan of seals, minimizing maintenance and downtime compared to traditional O-Rings.

Applications and Industry Uses

O-Rings are widely used in static sealing applications across automotive, aerospace, and hydraulic industries due to their simplicity and cost-effectiveness. X-Rings, designed to reduce friction and improve sealing under dynamic conditions, are preferred in high-performance machinery, motorcycles, and industrial equipment where enhanced durability and leak prevention are critical. Your choice between O-Ring and X-Ring depends on the specific demands of the application, including pressure, movement, and environmental factors.

Installation and Maintenance

O-Rings offer straightforward installation due to their simple circular design that fits easily into grooves, minimizing the risk of misalignment during assembly. X-Rings, with their four-lobed cross-section, require careful positioning to ensure optimal sealing performance but provide enhanced sealing under pressure, reducing maintenance frequency. Your choice between the two should consider the ease of installation and long-term maintenance demands for efficient system operation.

Cost Considerations

O-Rings generally cost less than X-Rings due to simpler manufacturing processes and widespread availability, making them a budget-friendly option for many sealing applications. X-Rings, with their more complex design offering improved sealing and reduced friction, often come at a higher price but can reduce long-term maintenance costs and downtime. Evaluating your specific application needs and sealing performance requirements will help determine if the higher upfront investment in X-Rings delivers better overall value for your project.

Choosing the Right Seal for Your Needs

Selecting the right seal depends on application requirements such as pressure, speed, and durability. O-rings offer excellent sealing performance in static or low-speed conditions, while X-rings provide enhanced sealing with reduced friction and better resistance to wear in dynamic environments. Understanding the specific operating conditions will ensure optimal choice between O-ring and X-ring seals for longevity and efficiency.

O-Ring vs X-Ring Infographic

libmatt.com

libmatt.com