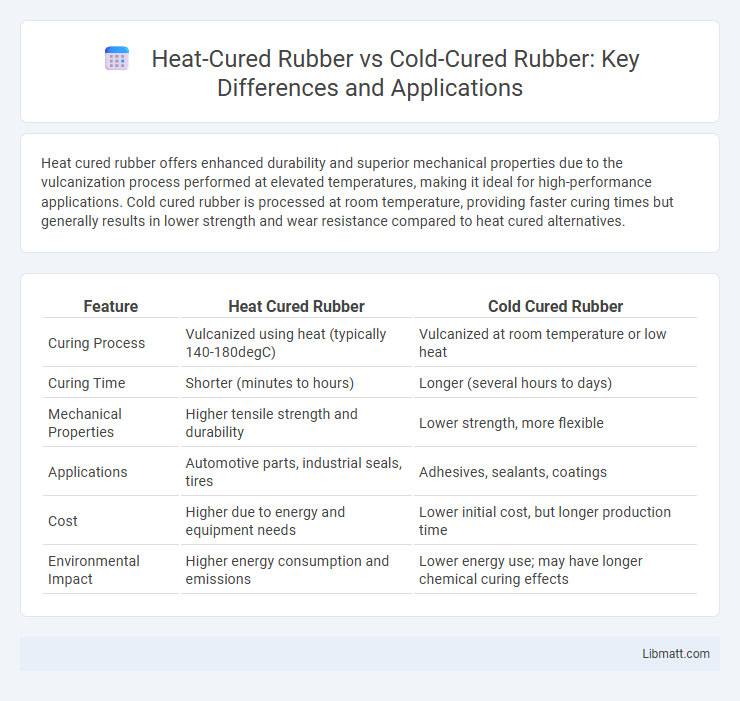

Heat cured rubber offers enhanced durability and superior mechanical properties due to the vulcanization process performed at elevated temperatures, making it ideal for high-performance applications. Cold cured rubber is processed at room temperature, providing faster curing times but generally results in lower strength and wear resistance compared to heat cured alternatives.

Table of Comparison

| Feature | Heat Cured Rubber | Cold Cured Rubber |

|---|---|---|

| Curing Process | Vulcanized using heat (typically 140-180degC) | Vulcanized at room temperature or low heat |

| Curing Time | Shorter (minutes to hours) | Longer (several hours to days) |

| Mechanical Properties | Higher tensile strength and durability | Lower strength, more flexible |

| Applications | Automotive parts, industrial seals, tires | Adhesives, sealants, coatings |

| Cost | Higher due to energy and equipment needs | Lower initial cost, but longer production time |

| Environmental Impact | Higher energy consumption and emissions | Lower energy use; may have longer chemical curing effects |

Introduction to Cured Rubber

Heat cured rubber undergoes vulcanization using elevated temperatures, enhancing cross-linking efficiency for improved mechanical strength, elasticity, and chemical resistance. Cold cured rubber relies on room-temperature curing agents that initiate polymer cross-linking without external heat, resulting in longer curing times and generally lower mechanical properties. The choice between heat cured and cold cured rubber depends on application requirements such as durability, production speed, and thermal stability.

What is Heat Cured Rubber?

Heat cured rubber is a type of elastomer that undergoes vulcanization through the application of heat, creating strong cross-links between polymer chains to enhance durability and elasticity. This curing process typically occurs at temperatures between 140degC and 180degC, resulting in improved mechanical properties and resistance to wear, chemicals, and temperature variations. Heat cured rubber is widely used in automotive parts, industrial seals, and molded rubber products due to its superior performance and longevity compared to cold cured rubber.

What is Cold Cured Rubber?

Cold cured rubber refers to rubber compounds that are vulcanized at lower temperatures, typically below 100degC, using chemical agents rather than heat. This curing process allows for faster production and improved physical properties such as enhanced elasticity and resistance to environmental factors. Unlike heat cured rubber, cold cured rubber often exhibits reduced shrinkage and better flexibility, making it suitable for applications requiring precise dimensional stability.

Key Differences Between Heat and Cold Curing

Heat cured rubber undergoes vulcanization at elevated temperatures, resulting in faster cross-linking and enhanced mechanical properties such as increased tensile strength and elasticity. Cold cured rubber, on the other hand, cures at room temperature through chemical reactions that take longer and typically produce a softer, more flexible material with lower tensile strength. Your choice between heat and cold cured rubber depends on the required durability, curing time, and specific application needs.

Advantages of Heat Cured Rubber

Heat cured rubber offers superior mechanical strength, enhanced elasticity, and better resistance to heat, chemicals, and wear compared to cold cured rubber. This improved durability extends the lifespan of rubber products, making them ideal for demanding industrial applications. Your choice of heat cured rubber ensures reliable performance under high-temperature conditions and heavy mechanical stress.

Benefits of Cold Cured Rubber

Cold cured rubber offers enhanced flexibility and faster curing times compared to heat cured rubber, making it ideal for applications requiring quick turnaround and precise molding. Its low-temperature processing reduces the risk of thermal degradation, preserving the material's mechanical properties and extending product lifespan. Cost-effectiveness and energy efficiency are additional benefits, as cold curing eliminates the need for high-temperature ovens, reducing operational expenses.

Common Applications of Heat Cured Rubber

Heat cured rubber is widely used in automotive components, industrial seals, and high-performance gaskets due to its enhanced durability and resistance to heat and chemical exposure. Its ability to maintain structural integrity at elevated temperatures makes it ideal for manufacturing tires, conveyor belts, and vibration dampers. This curing method also supports the production of medical devices and aerospace parts that demand strict material specifications.

Typical Uses for Cold Cured Rubber

Cold cured rubber is commonly used in applications requiring flexibility and rapid curing at lower temperatures, such as adhesives, sealants, and electrical insulation. It is preferred for coating or encapsulating delicate components where heat exposure could cause damage or deformation. Typical industries utilizing cold cured rubber include automotive, aerospace, and electronics due to its ability to maintain properties without high-temperature processing.

Durability and Performance Comparison

Heat cured rubber offers superior durability due to its enhanced cross-linking during the vulcanization process, resulting in higher resistance to wear, heat, and chemical exposure compared to cold cured rubber. Cold cured rubber, while easier and faster to produce, typically exhibits lower tensile strength and less resilience under extreme conditions, making it less suitable for heavy-duty applications. Choosing heat cured rubber for your projects ensures better long-term performance and reliability in demanding environments.

Choosing the Right Curing Method for Your Needs

Heat cured rubber undergoes vulcanization at elevated temperatures, resulting in enhanced durability, strength, and resistance to wear, making it ideal for high-stress applications. Cold cured rubber cures at room temperature using specialized chemicals, allowing for faster production and suitability for delicate or temperature-sensitive materials. Your choice depends on the required mechanical properties, production speed, and environmental constraints specific to your project.

Heat cured rubber vs Cold cured rubber Infographic

libmatt.com

libmatt.com