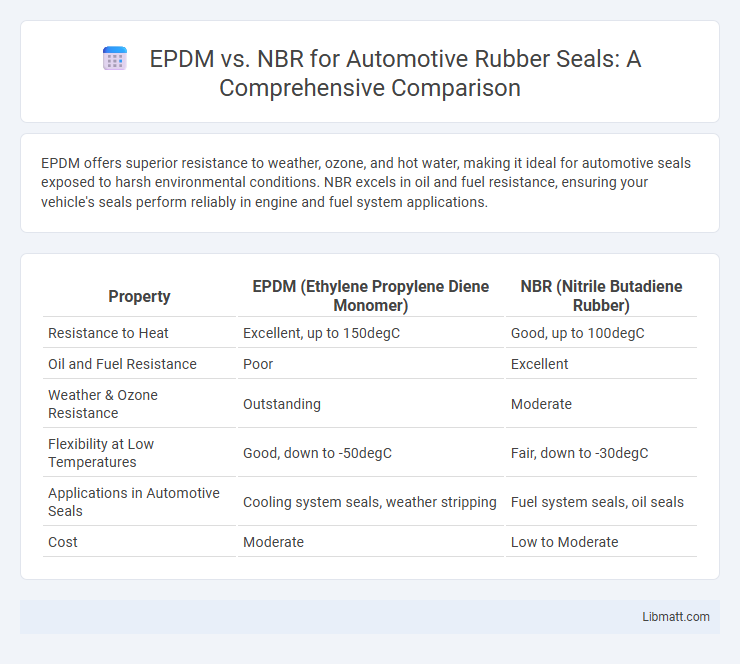

EPDM offers superior resistance to weather, ozone, and hot water, making it ideal for automotive seals exposed to harsh environmental conditions. NBR excels in oil and fuel resistance, ensuring your vehicle's seals perform reliably in engine and fuel system applications.

Table of Comparison

| Property | EPDM (Ethylene Propylene Diene Monomer) | NBR (Nitrile Butadiene Rubber) |

|---|---|---|

| Resistance to Heat | Excellent, up to 150degC | Good, up to 100degC |

| Oil and Fuel Resistance | Poor | Excellent |

| Weather & Ozone Resistance | Outstanding | Moderate |

| Flexibility at Low Temperatures | Good, down to -50degC | Fair, down to -30degC |

| Applications in Automotive Seals | Cooling system seals, weather stripping | Fuel system seals, oil seals |

| Cost | Moderate | Low to Moderate |

Introduction to EPDM and NBR in Automotive Seals

EPDM (ethylene propylene diene monomer) and NBR (nitrile butadiene rubber) are commonly used elastomers in automotive seals, each offering distinct properties tailored for specific applications. EPDM exhibits excellent resistance to heat, ozone, and weathering, making it ideal for exterior seals exposed to harsh environmental conditions. NBR provides superior resistance to oils, fuels, and chemicals, which suits it for seals in engine compartments and fuel systems.

Material Composition and Properties

EPDM (Ethylene Propylene Diene Monomer) consists of a synthetic rubber with excellent resistance to heat, ozone, and weathering, making it ideal for automotive seals exposed to harsh environments. NBR (Nitrile Butadiene Rubber) is a copolymer of acrylonitrile and butadiene, offering exceptional oil, fuel, and chemical resistance, which suits seals exposed to petroleum-based fluids. The distinct material compositions result in EPDM providing superior flexibility and aging resistance, while NBR excels in durability against oils and fuels in automotive sealing applications.

Temperature Resistance Comparison

EPDM outperforms NBR in temperature resistance, maintaining functionality in extreme environments ranging from -40degC to 150degC, whereas NBR operates effectively between -30degC and 100degC. The superior heat resistance of EPDM makes it ideal for seals exposed to high engine temperatures and steam, while NBR excels in oil and fuel resistance but has limited thermal tolerance. Your choice between EPDM and NBR for automotive seals should consider the specific temperature demands of your application to ensure optimal performance and longevity.

Chemical Compatibility in Automotive Applications

EPDM exhibits superior chemical compatibility with automotive fluids such as brake fluids, glycol-based coolants, and water, making it ideal for sealing applications exposed to these substances. NBR offers excellent resistance to petroleum-based oils, fuels, and greases, which are common in engine compartments and fuel systems. Selecting between EPDM and NBR depends on the specific fluid environment within the vehicle, ensuring optimal seal performance and longevity.

Weathering and Ozone Resistance

EPDM exhibits superior weathering and ozone resistance compared to NBR, making it ideal for automotive seals exposed to harsh outdoor conditions. NBR, while excellent for oil and fuel resistance, degrades faster when subjected to prolonged UV exposure and ozone, reducing seal longevity. Choosing EPDM for your automotive seals ensures enhanced durability and reliability in extreme environmental conditions.

Cost Analysis: EPDM vs NBR

EPDM rubber typically offers better cost efficiency for automotive seals due to its lower raw material price and excellent resistance to weathering, ozone, and heat, reducing long-term maintenance expenses. NBR, while often more expensive upfront, provides superior oil and fuel resistance, which can lower costs in applications exposed to petroleum-based fluids. Your choice between EPDM and NBR should balance initial material costs with the specific chemical and environmental exposure of the automotive seal to optimize overall performance and budget.

Durability and Longevity

EPDM offers superior resistance to heat, ozone, and weathering, making it highly durable for automotive seals exposed to harsh environmental conditions. NBR excels in oil, fuel, and chemical resistance but tends to degrade faster under prolonged UV and ozone exposure, reducing its longevity in external applications. Choosing EPDM enhances the lifespan of seals in engine bays and exterior parts, while NBR is preferred for seals in fuel systems due to its robust hydrocarbon resistance.

Typical Automotive Applications for EPDM and NBR

EPDM is widely used in automotive seals for weatherstripping, window seals, and coolant system gaskets due to its excellent resistance to heat, ozone, and weather conditions. NBR is preferred in fuel system seals, oil-resistant gaskets, and transmission seals because of its superior resistance to petroleum-based fluids and oils. Choosing the right material ensures Your automotive seals perform reliably under specific environmental and chemical exposures.

Installation and Maintenance Considerations

EPDM automotive seals offer superior resistance to heat, ozone, and weathering, making installation easier in high-temperature engine environments and requiring less frequent maintenance. NBR seals provide excellent oil and fuel resistance but may degrade faster under extreme heat, necessitating more frequent inspections and replacement during maintenance. Choosing EPDM or NBR depends on the vehicle's exposure to fluids and temperature variations, impacting seal longevity and maintenance schedules.

Choosing the Right Elastomer for Your Automotive Seals

EPDM offers exceptional resistance to weathering, ozone, and steam, making it ideal for automotive seals exposed to harsh environmental conditions and high temperatures. NBR excels in oil, fuel, and chemical resistance, ensuring durability in seals frequently contacting engine fluids and hydrocarbons. Selecting the right elastomer depends on the specific application environment, with EPDM preferred for exterior and high-temperature parts, while NBR is optimal for fuel system and oil-exposed components.

EPDM vs NBR for Automotive Seals Infographic

libmatt.com

libmatt.com