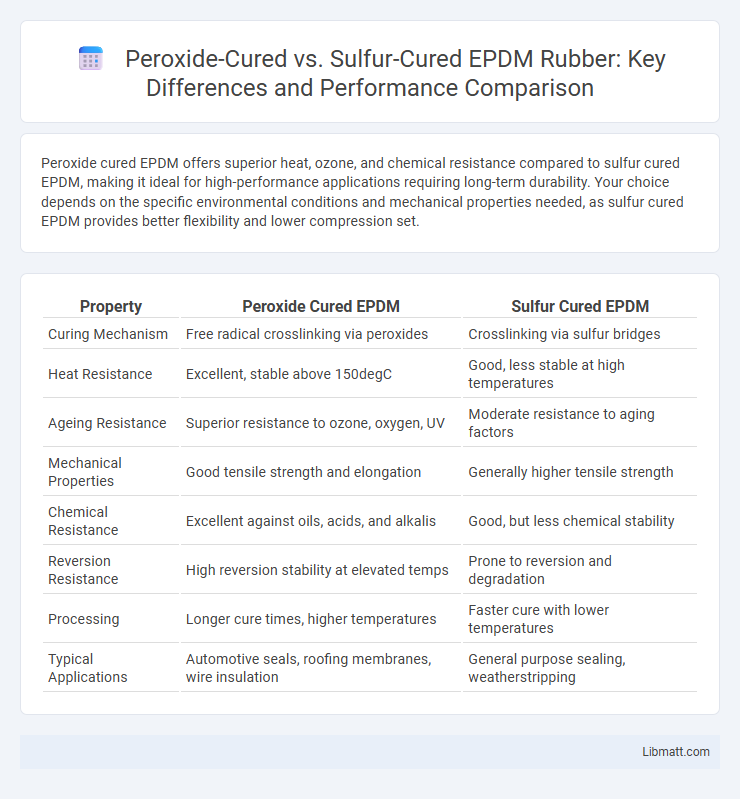

Peroxide cured EPDM offers superior heat, ozone, and chemical resistance compared to sulfur cured EPDM, making it ideal for high-performance applications requiring long-term durability. Your choice depends on the specific environmental conditions and mechanical properties needed, as sulfur cured EPDM provides better flexibility and lower compression set.

Table of Comparison

| Property | Peroxide Cured EPDM | Sulfur Cured EPDM |

|---|---|---|

| Curing Mechanism | Free radical crosslinking via peroxides | Crosslinking via sulfur bridges |

| Heat Resistance | Excellent, stable above 150degC | Good, less stable at high temperatures |

| Ageing Resistance | Superior resistance to ozone, oxygen, UV | Moderate resistance to aging factors |

| Mechanical Properties | Good tensile strength and elongation | Generally higher tensile strength |

| Chemical Resistance | Excellent against oils, acids, and alkalis | Good, but less chemical stability |

| Reversion Resistance | High reversion stability at elevated temps | Prone to reversion and degradation |

| Processing | Longer cure times, higher temperatures | Faster cure with lower temperatures |

| Typical Applications | Automotive seals, roofing membranes, wire insulation | General purpose sealing, weatherstripping |

Introduction to EPDM Rubber Compounds

EPDM rubber compounds are widely used in automotive, construction, and electrical applications due to their excellent weather, heat, and chemical resistance. Peroxide cured EPDM offers superior high-temperature stability and improved aging resistance compared to sulfur cured EPDM, which provides better elasticity and cost-effectiveness. The choice between peroxide and sulfur curing impacts the compound's final mechanical properties, durability, and specific use cases.

Overview of Peroxide Cured EPDM

Peroxide cured EPDM offers superior thermal stability and ozone resistance compared to sulfur cured EPDM, making it ideal for high-temperature applications and outdoor exposure. The peroxide curing process creates carbon-carbon crosslinks, which enhance mechanical strength and durability under harsh environmental conditions. This curing method also reduces the risk of reversion, ensuring long-term performance in automotive, roofing, and electrical insulation industries.

Overview of Sulfur Cured EPDM

Sulfur cured EPDM utilizes sulfur as a crosslinking agent, forming polysulfidic bridges that enhance elasticity and resilience in rubber compounds. This curing method improves tensile strength, abrasion resistance, and flexibility under dynamic conditions, making it suitable for automotive seals, roofing membranes, and weatherstripping applications. The sulfur cure process typically operates at lower temperatures and shorter times compared to peroxide curing, resulting in cost-effective production with reliable mechanical properties.

Crosslinking Mechanisms: Peroxide vs Sulfur

Peroxide cured EPDM utilizes free radical crosslinking where organic peroxides decompose to form radicals that initiate carbon-carbon bond formation, resulting in superior heat and chemical resistance. Sulfur cured EPDM relies on polysulfidic linkages formed through vulcanization, creating sulfur bridge crosslinks that provide flexibility but are more prone to degradation under heat and ozone exposure. Your choice between peroxide and sulfur curing depends on the desired balance of mechanical properties and environmental durability in EPDM applications.

Mechanical Properties Comparison

Peroxide cured EPDM typically exhibits superior heat aging resistance, improved tensile strength, and better compression set retention compared to sulfur cured EPDM, making it ideal for applications requiring long-term durability under harsh conditions. Sulfur cured EPDM often demonstrates faster curing times and enhanced flexibility but may suffer from slightly lower mechanical strength and reduced resistance to thermal degradation. Your choice between peroxide and sulfur cured EPDM should depend on the mechanical performance priorities specific to your application environment.

Heat and Aging Resistance of EPDM Cures

Peroxide cured EPDM exhibits superior heat and aging resistance compared to sulfur cured EPDM due to its stable carbon-carbon crosslinks, which maintain integrity at elevated temperatures and under prolonged oxidative exposure. In contrast, sulfur cured EPDM relies on sulfur-carbon bonds that degrade more quickly under heat, leading to diminished mechanical properties over time. You will benefit from choosing peroxide curing when long-term durability and resistance to thermal aging are critical for your EPDM applications.

Chemical and Weathering Resistance

Peroxide-cured EPDM exhibits superior chemical resistance to hydrocarbons, oils, and solvents compared to sulfur-cured EPDM, making it ideal for harsh chemical environments. It also demonstrates enhanced weathering resistance, maintaining elasticity and physical properties after prolonged exposure to UV radiation, ozone, and heat. Sulfur-cured EPDM, while cost-effective, tends to have lower resistance to oxidation and environmental degradation, limiting its durability in extreme outdoor conditions.

Processing and Manufacturing Differences

Peroxide cured EPDM uses organic peroxides as crosslinking agents, which require higher processing temperatures and offer better heat resistance and aging properties during manufacturing. Sulfur cured EPDM involves slower vulcanization at lower temperatures, providing enhanced flexibility but with potential issues like reversion and less thermal stability. Your choice between these curing methods affects cycle time, equipment settings, and final product durability.

Cost Implications and Application Suitability

Peroxide cured EPDM generally incurs higher initial costs due to specialized curing agents and longer curing times, but it delivers superior heat resistance and durability suitable for high-performance automotive and industrial applications. Sulfur cured EPDM offers a more cost-effective solution with faster processing times, making it ideal for general-purpose seals and weatherstripping where extreme chemical resistance is not critical. Your choice between these curing methods should balance upfront expenses against long-term performance requirements and environmental exposure conditions.

Choosing the Right EPDM Cure: Key Considerations

Peroxide cured EPDM offers superior heat and ozone resistance with cleaner cross-linking, making it ideal for high-performance applications requiring long-term durability. Sulfur cured EPDM provides excellent elasticity and cost-effectiveness, suitable for general-purpose seals and gaskets in standard environments. Understanding your application's temperature, chemical exposure, and mechanical demands will guide you in selecting the right cure for optimal EPDM performance.

Peroxide cured EPDM vs Sulfur cured EPDM Infographic

libmatt.com

libmatt.com