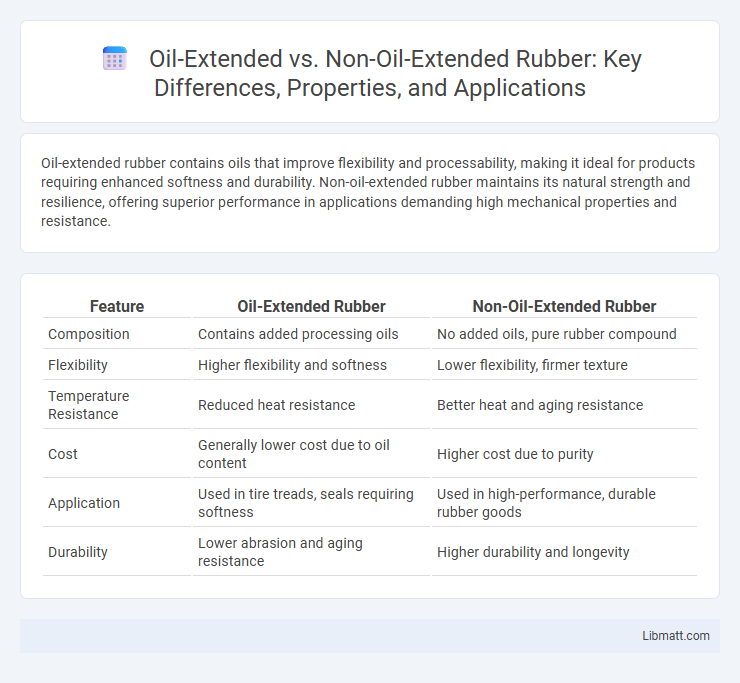

Oil-extended rubber contains oils that improve flexibility and processability, making it ideal for products requiring enhanced softness and durability. Non-oil-extended rubber maintains its natural strength and resilience, offering superior performance in applications demanding high mechanical properties and resistance.

Table of Comparison

| Feature | Oil-Extended Rubber | Non-Oil-Extended Rubber |

|---|---|---|

| Composition | Contains added processing oils | No added oils, pure rubber compound |

| Flexibility | Higher flexibility and softness | Lower flexibility, firmer texture |

| Temperature Resistance | Reduced heat resistance | Better heat and aging resistance |

| Cost | Generally lower cost due to oil content | Higher cost due to purity |

| Application | Used in tire treads, seals requiring softness | Used in high-performance, durable rubber goods |

| Durability | Lower abrasion and aging resistance | Higher durability and longevity |

Introduction to Oil-Extended and Non-Oil-Extended Rubber

Oil-extended rubber contains added processing oils that enhance flexibility, improve low-temperature performance, and reduce viscosity during manufacturing, making it ideal for applications requiring enhanced elasticity and easier molding. Non-oil-extended rubber, lacking these oils, offers superior strength, abrasion resistance, and better heat aging properties, suitable for heavy-duty uses where durability is critical. Understanding the differences between oil-extended and non-oil-extended rubber helps you select the best material for your specific industrial or commercial needs.

Defining Oil-Extended Rubber: Composition and Properties

Oil-extended rubber is a type of synthetic or natural rubber mixed with specific oils to improve flexibility, softness, and processing characteristics. Its composition typically includes base polymers combined with extender oils that reduce viscosity, enhance elongation, and provide better resistance to low temperatures. Your choice of oil-extended rubber affects product durability and performance, especially in applications requiring enhanced elasticity and ease of molding.

Understanding Non-Oil-Extended Rubber: Features and Characteristics

Non-oil-extended rubber is a type of synthetic or natural rubber that does not contain processing oils, resulting in a higher concentration of elastomeric materials. This rubber variant exhibits superior mechanical properties such as enhanced tensile strength, improved abrasion resistance, and better heat aging stability compared to oil-extended counterparts. Its lower oil content makes it ideal for applications requiring higher durability, elasticity, and resistance to oil swelling or degradation.

Manufacturing Processes: Oil-Extended vs Non-Oil-Extended Rubber

Oil-extended rubber involves incorporating processing oils during mixing to improve flow characteristics and reduce viscosity, facilitating easier shaping and extrusion in manufacturing. Non-oil-extended rubber relies solely on the natural or synthetic polymer matrix without oil additives, resulting in higher viscosity that may require more intensive processing conditions. Your choice between these types directly impacts equipment requirements, energy consumption, and final product properties in rubber manufacturing.

Performance Differences: Durability and Flexibility

Oil-extended rubber offers enhanced flexibility due to the added oils, which act as plasticizers, improving the material's stretchability and softness. Non-oil-extended rubber, meanwhile, typically provides superior durability and resistance to wear and tear, as it contains fewer additives that can degrade over time. Your choice between these two materials will depend on whether your application prioritizes flexibility for dynamic movement or long-lasting durability for heavy-duty use.

Cost Analysis: Economies of Oil-Extension

Oil-extended rubber significantly reduces production costs by incorporating inexpensive extender oils, enabling manufacturers to achieve economies of scale through lower raw material expenses. The cost advantage arises from using less natural or synthetic rubber, which is typically more expensive, thereby improving profit margins without substantially compromising material properties. Non-oil-extended rubber maintains higher purity and performance but incurs greater costs due to reliance solely on natural or synthetic rubber without cost-reducing additives.

Applications in Industry: Choosing the Right Rubber Type

Oil-extended rubber, enhanced with petroleum-based plasticizers, offers superior flexibility and improved low-temperature performance, making it ideal for automotive seals, hoses, and industrial gaskets requiring resilience under varying conditions. Non-oil-extended rubber provides higher tensile strength and better chemical resistance, preferred in tire manufacturing, conveyor belts, and heavy-duty industrial components demanding durability and longevity. Selecting the right rubber type depends on specific application requirements such as temperature range, mechanical stress, and exposure to oils or chemicals in industrial settings.

Environmental and Health Considerations

Oil-extended rubber poses significant environmental concerns due to the use of petroleum-based oils, which can release harmful volatile organic compounds (VOCs) and contribute to soil and water pollution during production and disposal. Non-oil-extended rubber, often formulated with bio-based or synthetic alternatives, offers improved health and environmental profiles by reducing toxic emissions and minimizing ecological impact. Choosing non-oil-extended rubber can enhance the sustainability of Your products by lowering exposure to hazardous chemicals and supporting cleaner manufacturing processes.

Market Trends and Demand for Each Rubber Type

Oil-extended rubber continues to experience steady demand in markets prioritizing cost efficiency and enhanced processing properties, especially in automotive and tire manufacturing industries. Non-oil-extended rubber sees growing preference in eco-conscious sectors and high-performance applications due to its superior durability and lower environmental impact. Your choice between these rubber types should consider evolving market trends favoring sustainability and performance-driven materials.

Conclusion: Selecting Between Oil-Extended and Non-Oil-Extended Rubber

Choosing between oil-extended and non-oil-extended rubber depends on the application's need for flexibility, processability, and performance under stress. Oil-extended rubber offers enhanced flexibility and easier processing due to plasticizer oils, making it ideal for products like shoe soles and adhesives requiring softness and elasticity. Non-oil-extended rubber provides superior strength and resistance to heat and chemicals, suitable for heavy-duty applications such as automotive parts and industrial seals.

Oil-extended vs Non-oil-extended rubber Infographic

libmatt.com

libmatt.com