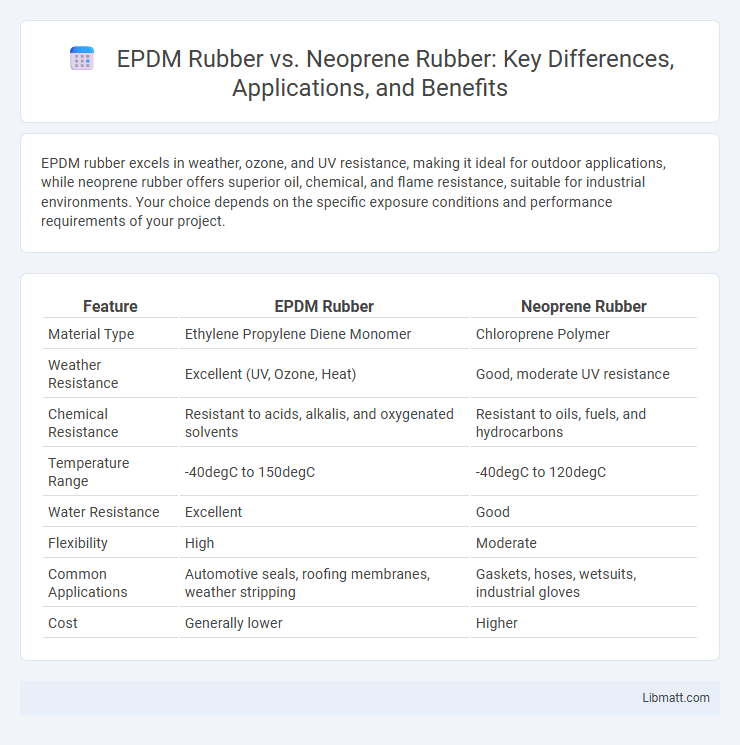

EPDM rubber excels in weather, ozone, and UV resistance, making it ideal for outdoor applications, while neoprene rubber offers superior oil, chemical, and flame resistance, suitable for industrial environments. Your choice depends on the specific exposure conditions and performance requirements of your project.

Table of Comparison

| Feature | EPDM Rubber | Neoprene Rubber |

|---|---|---|

| Material Type | Ethylene Propylene Diene Monomer | Chloroprene Polymer |

| Weather Resistance | Excellent (UV, Ozone, Heat) | Good, moderate UV resistance |

| Chemical Resistance | Resistant to acids, alkalis, and oxygenated solvents | Resistant to oils, fuels, and hydrocarbons |

| Temperature Range | -40degC to 150degC | -40degC to 120degC |

| Water Resistance | Excellent | Good |

| Flexibility | High | Moderate |

| Common Applications | Automotive seals, roofing membranes, weather stripping | Gaskets, hoses, wetsuits, industrial gloves |

| Cost | Generally lower | Higher |

Introduction to EPDM Rubber and Neoprene Rubber

EPDM rubber is a synthetic elastomer known for its exceptional resistance to weather, ozone, and UV exposure, making it ideal for outdoor applications such as roofing, seals, and gaskets. Neoprene rubber, also a synthetic elastomer, excels in oil, chemical, and heat resistance, commonly used in automotive parts, wetsuits, and industrial applications. Your choice between EPDM and neoprene depends on specific environmental conditions and performance requirements.

Chemical Composition and Structure

EPDM rubber consists of ethylene, propylene, and a diene monomer, forming a saturated polymer chain with excellent resistance to ozone, heat, and weathering. Neoprene rubber is made from polychloroprene, a chlorinated synthetic rubber, providing strong resistance to oils, chemicals, and flame. The presence of chlorine in neoprene's molecular structure differentiates its chemical stability and flexibility compared to the hydrocarbon backbone of EPDM.

Key Physical Properties Comparison

EPDM rubber excels in weather resistance, UV stability, and flexibility at low temperatures, making it ideal for outdoor applications, while neoprene rubber offers superior oil, chemical, and flame resistance. EPDM has a tensile strength typically ranging from 7 to 20 MPa and maintains elasticity between -40degC to 125degC; neoprene generally provides tensile strength from 5 to 12 MPa and performs effectively within -40degC to 100degC. Understanding these key physical properties helps you select the optimal material for specific environmental conditions and performance requirements.

Weather and UV Resistance

EPDM rubber exhibits superior weather and UV resistance compared to neoprene rubber, making it ideal for prolonged outdoor exposure in harsh environments. Its molecular structure effectively withstands ozone, sunlight, and extreme temperatures without significant degradation. Your applications requiring durable sealing or insulation benefit from EPDM's enhanced longevity under severe weather conditions.

Chemical and Oil Resistance

EPDM rubber excels in resistance to acids, alkalis, and oxygenated solvents, making it ideal for outdoor applications exposed to weather and ozone, but it performs poorly against petroleum oils and solvents. Neoprene rubber offers superior resistance to oils, greases, and hydrocarbons, providing robust protection in automotive and industrial environments where exposure to chemicals and oils is frequent. Your choice between EPDM and Neoprene should hinge on the specific chemical exposure and oil resistance your application demands.

Temperature Tolerance Ranges

EPDM rubber exhibits exceptional temperature tolerance, functioning effectively in extreme conditions ranging from -40degF to 300degF, making it ideal for outdoor and automotive applications exposed to heat and sunlight. Neoprene rubber operates within a narrower temperature range of approximately -40degF to 210degF, offering good resistance to oils and chemicals but less heat resilience than EPDM. Your choice between these materials should consider the specific temperature demands of your application to ensure optimal performance and durability.

Common Industrial and Commercial Applications

EPDM rubber excels in outdoor applications due to its superior resistance to weathering, ozone, and UV exposure, making it ideal for roofing materials, automotive seals, and window gaskets. Neoprene rubber is preferred in environments requiring oil, chemical, and heat resistance, commonly used in wetsuits, industrial hoses, and conveyor belts. Your choice between EPDM and neoprene should depend on the specific environmental conditions and chemical exposures your application demands.

Installation and Maintenance Considerations

EPDM rubber offers superior weather resistance and flexibility, making it easier to install in outdoor applications with minimal maintenance requirements. Neoprene rubber requires careful handling during installation to prevent damage from solvents and UV exposure, and periodic maintenance is needed to maintain its chemical and oil resistance. Choosing between EPDM and Neoprene depends on the specific environmental conditions and long-term durability needs of the project.

Environmental Impact and Sustainability

EPDM rubber offers superior environmental benefits due to its excellent resistance to weathering, UV rays, and ozone, which extends product lifespan and reduces waste. Neoprene rubber, while durable, involves chloroprene production that emits harmful chemicals and has a higher environmental footprint. Choosing EPDM supports your sustainability goals by minimizing ecological impact through longer durability and safer manufacturing processes.

Cost Analysis and Final Selection Guide

EPDM rubber generally offers a lower initial cost and superior resistance to weather, ozone, and UV exposure, making it ideal for outdoor applications, while neoprene rubber tends to be more expensive but provides better oil, chemical, and flame resistance. Your final selection depends on evaluating the specific environmental conditions and budget constraints: choose EPDM for cost-effective durability in harsh weather or neoprene for enhanced chemical resilience despite higher upfront costs. Consider lifecycle costs, including maintenance and replacement frequency, to optimize long-term value in your application.

EPDM Rubber vs Neoprene Rubber Infographic

libmatt.com

libmatt.com