IIR filters use feedback to create an infinite impulse response, making them efficient for real-time signal processing, while BIIR filters are a type of IIR filter optimized for specific applications, such as improved stability or performance in certain frequency ranges. Understanding the differences helps you select the appropriate filter type for your signal processing needs.

Table of Comparison

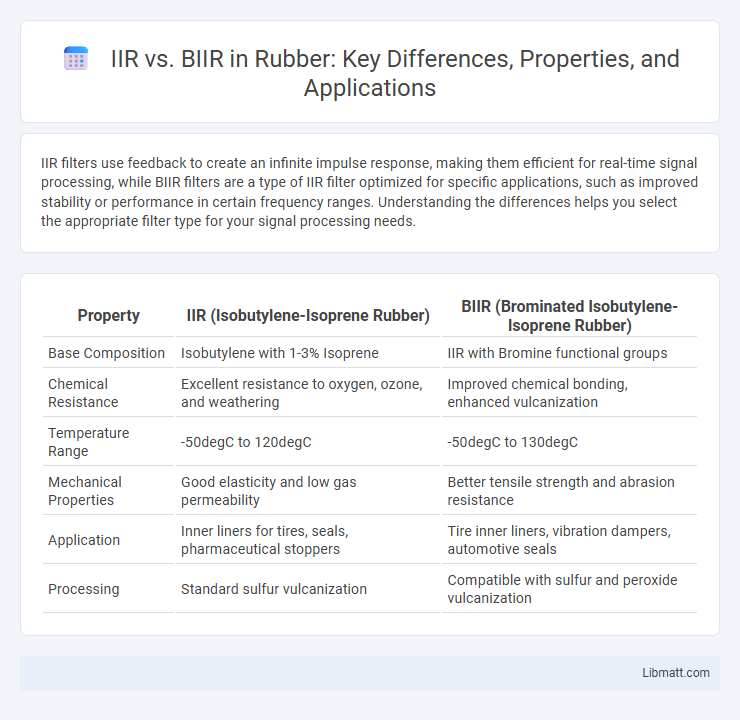

| Property | IIR (Isobutylene-Isoprene Rubber) | BIIR (Brominated Isobutylene-Isoprene Rubber) |

|---|---|---|

| Base Composition | Isobutylene with 1-3% Isoprene | IIR with Bromine functional groups |

| Chemical Resistance | Excellent resistance to oxygen, ozone, and weathering | Improved chemical bonding, enhanced vulcanization |

| Temperature Range | -50degC to 120degC | -50degC to 130degC |

| Mechanical Properties | Good elasticity and low gas permeability | Better tensile strength and abrasion resistance |

| Application | Inner liners for tires, seals, pharmaceutical stoppers | Tire inner liners, vibration dampers, automotive seals |

| Processing | Standard sulfur vulcanization | Compatible with sulfur and peroxide vulcanization |

Introduction to IIR and BIIR

Infinite Impulse Response (IIR) filters use feedback to create an output dependent on both current and past input values, enabling efficient real-time signal processing with fewer coefficients. Bounded-Input Bounded-Output IIR (BIIR) filters extend the IIR concept by ensuring system stability for all bounded inputs, a critical property for reliable performance in control and communication systems. Understanding the differences between IIR and BIIR filters helps optimize Your signal processing applications for stability and efficiency.

Definition and Composition of IIR

Infinite Impulse Response (IIR) filters process signals using feedback, where the output depends on both current and past input values as well as previous outputs, characterized by a recursive difference equation. The composition of an IIR filter includes feedforward coefficients associated with the input signal and feedback coefficients linked to the output, enabling efficient realization with fewer coefficients compared to FIR filters. Understanding the recursive nature and coefficient structure of IIR filters can help you design systems with sharper frequency responses and lower computational complexity.

Definition and Composition of BIIR

BIIR (Bi-Impulse Infrared) represents an advanced iteration of traditional IIR (Impulse Infrared) sensors, incorporating dual impulse technology to enhance signal accuracy and sensitivity. Unlike standard IIR devices, BIIR combines two infrared pulses with sophisticated filtering algorithms, enabling more precise detection in complex environments. Your applications benefit from BIIR's improved noise resistance and reliability, crucial for tasks requiring high-performance infrared sensing.

Key Differences Between IIR and BIIR

IIR (Infinite Impulse Response) filters have feedback loops that cause their output to depend on both current and past inputs as well as past outputs, while BIIR (Bidirectional Infinite Impulse Response) filters process signals in two directions, forward and backward, to achieve zero-phase distortion. Your choice between IIR and BIIR depends on whether phase linearity or computational efficiency is more critical for your application. BIIR filters typically provide better phase characteristics at the cost of increased computational complexity compared to standard IIR filters.

Mechanical Properties Comparison

IIR (Isobutylene Isoprene Rubber) offers superior elasticity and compression set resistance, making it ideal for dynamic sealing applications requiring durable mechanical performance. BIIR (Bromo Isobutylene Isoprene Rubber) enhances these properties by improved resistance to heat, aging, and ozone, resulting in better overall mechanical robustness in harsh environments. Your choice between IIR and BIIR should consider the specific mechanical demands, such as tensile strength and elongation, based on application conditions.

Chemical Resistance and Applications

IIR (Butyl Rubber) exhibits excellent chemical resistance to polar solvents, acids, and alkalis, making it ideal for industrial sealing, chemical handling, and pharmaceutical packaging. BIIR (Bromo-Butyl Rubber) enhances this resistance by adding improved compatibility with oils, fuels, and aromatic hydrocarbons, expanding its applications to automotive inner tubes, tire liners, and fuel system components. Your choice depends on the specific chemical exposure and durability requirements of your application.

Processing and Manufacturing Techniques

IIR (Isobutylene Isoprene Rubber) is produced through cationic polymerization, resulting in a highly saturated polymer that offers excellent resistance to heat, chemicals, and ozone, making it ideal for demanding industrial applications. BIIR (Brominated Isobutylene Isoprene Rubber) is synthesized by brominating IIR, which introduces reactive sites into the polymer chain, enhancing its compatibility with polar compounding ingredients and improving vulcanization efficiency. Your choice between IIR and BIIR affects processing techniques, as BIIR allows for faster curing and better adhesion in manufacturing processes like tire inner liners and specialty rubber components.

Cost Analysis: IIR vs BIIR

IIR filters generally offer lower computational complexity, resulting in reduced hardware costs and power consumption compared to BIIR filters, which are more resource-intensive due to their block-based processing structure. Your choice between IIR and BIIR impacts overall system cost, as BIIR implementations often require additional memory and processing units, increasing design and manufacturing expenses. Efficient cost management favors IIR filters in applications with tight budget constraints, while BIIR may justify higher costs for performance in specific signal processing tasks.

Industry Usage and Market Trends

IIR (Infinite Impulse Response) filters dominate audio processing and telecommunications due to their efficiency and lower computational load, especially in real-time applications. BIIR filters, an advanced form of IIR, offer improved stability and phase response, making them increasingly popular in high-precision industries like aerospace and medical imaging. Your choice between IIR and BIIR will depend on specific industry requirements and evolving market trends favoring enhanced filter performance and reliability.

Choosing Between IIR and BIIR

Choosing between IIR (Infinite Impulse Response) and BIIR (Bilinear Infinite Impulse Response) filters depends on your system requirements for stability, computational efficiency, and filter design precision. BIIR filters leverage the bilinear transform to map analog filter designs to digital domains without frequency warping, offering improved phase characteristics and stability compared to traditional IIR filters. Your decision should weigh the trade-offs between computational complexity and desired filter performance in your specific application.

IIR vs BIIR Infographic

libmatt.com

libmatt.com