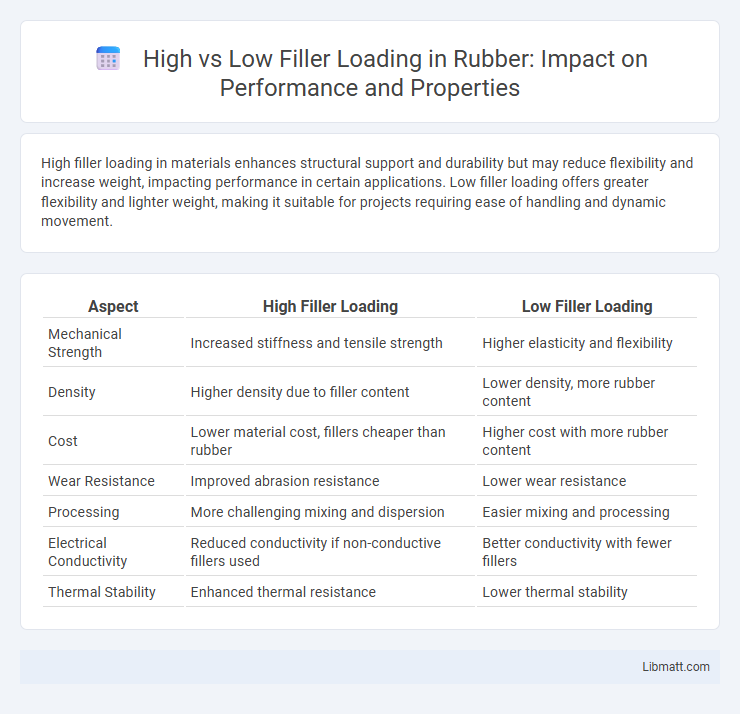

High filler loading in materials enhances structural support and durability but may reduce flexibility and increase weight, impacting performance in certain applications. Low filler loading offers greater flexibility and lighter weight, making it suitable for projects requiring ease of handling and dynamic movement.

Table of Comparison

| Aspect | High Filler Loading | Low Filler Loading |

|---|---|---|

| Mechanical Strength | Increased stiffness and tensile strength | Higher elasticity and flexibility |

| Density | Higher density due to filler content | Lower density, more rubber content |

| Cost | Lower material cost, fillers cheaper than rubber | Higher cost with more rubber content |

| Wear Resistance | Improved abrasion resistance | Lower wear resistance |

| Processing | More challenging mixing and dispersion | Easier mixing and processing |

| Electrical Conductivity | Reduced conductivity if non-conductive fillers used | Better conductivity with fewer fillers |

| Thermal Stability | Enhanced thermal resistance | Lower thermal stability |

Introduction to Filler Loading

Filler loading refers to the proportion of filler material incorporated into a composite or polymer matrix, significantly affecting its mechanical properties and cost efficiency. High filler loading enhances rigidity and thermal stability but may reduce flexibility and impact resistance, while low filler loading preserves ductility and ease of processing. Understanding filler loading helps you optimize material performance for specific applications by balancing strength, weight, and durability.

Defining High vs Low Filler Loading

High filler loading refers to a material composition where a significant proportion of fillers, such as calcium carbonate or silica, is added to the base polymer, enhancing properties like stiffness and reducing cost. Low filler loading involves minimal filler content, maintaining higher polymer characteristics such as flexibility and impact resistance. Understanding how your product's filler loading affects performance is crucial for optimizing mechanical properties and manufacturing efficiency.

Material Properties Affected by Filler Content

Filler loading significantly influences material properties such as mechanical strength, thermal stability, and density. High filler content typically enhances stiffness and reduces thermal expansion but may decrease impact resistance and flexibility. Your choice of filler loading must balance these trade-offs to meet specific performance requirements.

Impact on Mechanical Strength

High filler loading increases mechanical strength by enhancing rigidity and reducing polymer matrix deformation under stress. Low filler loading results in lower mechanical strength due to inadequate particle reinforcement and increased matrix flexibility. Your choice of filler content directly influences the durability and load-bearing capacity of the final composite material.

Effects on Processability and Manufacturing

High filler loading enhances mechanical strength and reduces raw material costs but can increase viscosity, leading to challenges in processability such as poor flow and higher extrusion pressure. Low filler loading improves material flow and ease of manufacturing processes like injection molding or extrusion but may result in lower structural performance and higher material expenses. Balancing filler concentration is critical for optimizing manufacturing efficiency and product quality in composite and polymer production.

Cost Implications of Filler Loading Levels

High filler loading in materials reduces overall production costs by replacing expensive resin with cheaper filler, which lowers raw material expenses and can improve profitability for your products. Low filler loading leads to higher raw material costs due to greater resin content but may enhance mechanical properties and finish quality, potentially reducing downstream processing or warranty costs. Balancing filler levels is crucial to optimizing cost-effectiveness without compromising product performance or durability.

Influences on Product Performance

Filler loading significantly influences product performance by affecting mechanical strength, flexibility, and thermal stability. High filler loading typically enhances rigidity and dimensional stability but may reduce flexibility and increase brittleness, whereas low filler loading offers better elasticity and surface finish but may compromise durability. Understanding these trade-offs allows you to optimize material formulations for specific applications, ensuring balanced performance characteristics tailored to your product requirements.

Environmental and Sustainability Considerations

High filler loading reduces the demand for resin, lowering the carbon footprint and conserving fossil resources, which enhances sustainability in manufacturing. Low filler loading requires more resin, increasing energy consumption and emissions during production. Optimizing filler loading balances performance and environmental impact, helping Your products meet eco-friendly standards and reduce waste.

Industry-Specific Applications

High filler loading enhances material density and improves cost-efficiency in industries like construction and automotive, where strength and durability are critical. Low filler loading offers superior flexibility and surface finish, making it ideal for electronics and medical device manufacturing. Your choice between high and low filler loading directly impacts product performance, weight, and manufacturing costs within specific industry applications.

Choosing the Optimal Filler Loading

Choosing the optimal filler loading balances mechanical strength and processability, where high filler loading enhances stiffness and thermal stability but may reduce flexibility and increase viscosity. Low filler loading improves flow and surface finish but might compromise durability and impact resistance. Understanding your application's performance requirements ensures the best filler concentration for maximum efficiency and product quality.

Filler loading: high vs low Infographic

libmatt.com

libmatt.com