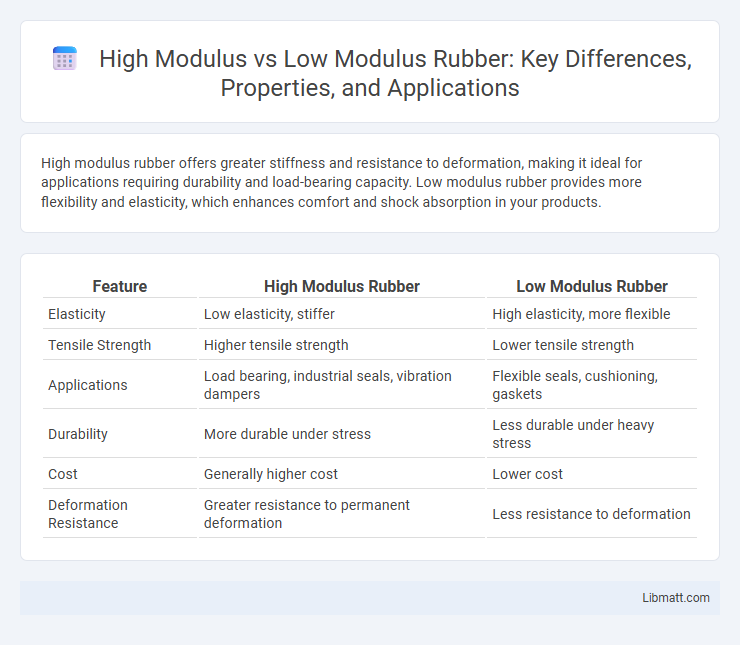

High modulus rubber offers greater stiffness and resistance to deformation, making it ideal for applications requiring durability and load-bearing capacity. Low modulus rubber provides more flexibility and elasticity, which enhances comfort and shock absorption in your products.

Table of Comparison

| Feature | High Modulus Rubber | Low Modulus Rubber |

|---|---|---|

| Elasticity | Low elasticity, stiffer | High elasticity, more flexible |

| Tensile Strength | Higher tensile strength | Lower tensile strength |

| Applications | Load bearing, industrial seals, vibration dampers | Flexible seals, cushioning, gaskets |

| Durability | More durable under stress | Less durable under heavy stress |

| Cost | Generally higher cost | Lower cost |

| Deformation Resistance | Greater resistance to permanent deformation | Less resistance to deformation |

Understanding Rubber Modulus: An Overview

Rubber modulus measures a material's resistance to deformation under stress, with high modulus rubber exhibiting greater stiffness and strength compared to low modulus types. High modulus rubber is preferred in applications requiring durability and shape retention, such as automotive seals and industrial belts, while low modulus rubber offers enhanced flexibility and cushioning, ideal for vibration damping and soft gaskets. Understanding the distinction between high and low modulus rubbers is crucial for selecting the appropriate material based on mechanical performance and specific use-case requirements.

What is High Modulus Rubber?

High modulus rubber exhibits a high stiffness and resistance to deformation, making it ideal for applications requiring strong load-bearing capabilities and dimensional stability. This type of elastomer has a significantly higher tensile strength and reduced elongation compared to low modulus rubber, enhancing durability in industrial seals, gaskets, and vibration dampening components. Its molecular structure is highly crosslinked, which contributes to its superior mechanical properties and resistance to wear under extreme conditions.

Characteristics of Low Modulus Rubber

Low modulus rubber exhibits high elasticity and flexibility, allowing it to stretch significantly under low stress without permanent deformation. It is commonly used in applications requiring cushioning, vibration dampening, and shock absorption due to its ability to maintain softness and recover shape quickly. Low modulus rubber typically has a Shore A hardness below 40, enhancing its suitability for seals, gaskets, and flexible connectors in automotive and industrial settings.

Key Differences Between High and Low Modulus Rubber

High modulus rubber exhibits greater stiffness and resistance to deformation under stress, making it ideal for applications requiring durability and structural integrity, such as automotive parts and industrial seals. Low modulus rubber offers enhanced flexibility and elasticity, allowing it to absorb vibrations and accommodate dynamic movements, commonly used in cushioning, gaskets, and flexible connectors. The key differences lie in their molecular structure and cross-link density, which directly influence their mechanical properties and suitability for specific engineering applications.

Applications of High Modulus Rubber

High modulus rubber features enhanced stiffness and tensile strength, making it ideal for demanding applications such as automotive engine mounts, industrial vibration dampers, and heavy-duty conveyor belts. Its superior resistance to deformation under stress ensures longer durability and performance in structural components and sealing systems exposed to harsh environments. You can rely on high modulus rubber in settings requiring optimal mechanical stability and wear resistance.

Uses of Low Modulus Rubber in Various Industries

Low modulus rubber is widely utilized in industries requiring flexibility and resilience, such as automotive, medical, and consumer goods manufacturing. Its ability to endure significant deformation without permanent damage makes it ideal for seals, gaskets, and flexible connectors in machinery. In the footwear industry, low modulus rubber enhances comfort and durability by absorbing shocks and providing better flexibility.

Performance Factors: Strength, Flexibility, and Durability

High modulus rubber exhibits superior strength and rigidity, making it ideal for applications requiring high load-bearing capacity and minimal deformation under stress. Low modulus rubber offers enhanced flexibility and stretchability, providing better shock absorption and comfort in dynamic environments. Durability in high modulus rubber typically surpasses that of low modulus materials due to its resistance to wear and compression set, though low modulus rubber excels in environments demanding flexibility over long-term structural integrity.

Cost Implications: High vs Low Modulus Rubber

High modulus rubber typically incurs higher costs due to its enhanced mechanical properties and specialized applications requiring superior strength and durability. Low modulus rubber, being more flexible and easier to produce, generally offers a more cost-effective solution for applications with less demanding performance requirements. Choosing between high and low modulus rubber involves balancing initial material expenses with long-term performance benefits and potential maintenance savings.

Selection Criteria for Choosing Rubber Modulus

High modulus rubber provides superior stiffness and resistance to deformation, making it ideal for applications requiring durability under high stress and structural stability. Low modulus rubber offers greater flexibility and elasticity, suited for cushioning, vibration absorption, and dynamic movements where softness is crucial. Your selection criteria should consider load requirements, operational environment, and desired flexibility to ensure optimal material performance.

Future Trends in Rubber Modulus Technology

High modulus rubber materials are advancing rapidly with innovations in polymer chemistry and nanocomposite technology, delivering enhanced strength and durability for demanding industrial applications. Low modulus rubbers continue evolving through bio-based formulations and improved flexibility, optimizing comfort and environmental sustainability in consumer products. You can expect future rubber modulus technology to prioritize smart materials that adapt dynamically to stress, balancing performance with eco-friendly manufacturing processes.

High modulus vs Low modulus rubber Infographic

libmatt.com

libmatt.com