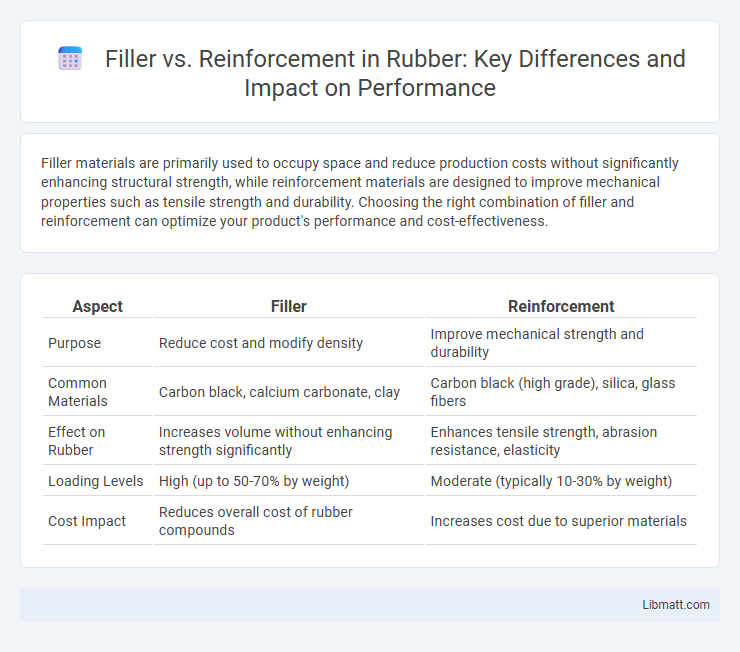

Filler materials are primarily used to occupy space and reduce production costs without significantly enhancing structural strength, while reinforcement materials are designed to improve mechanical properties such as tensile strength and durability. Choosing the right combination of filler and reinforcement can optimize your product's performance and cost-effectiveness.

Table of Comparison

| Aspect | Filler | Reinforcement |

|---|---|---|

| Purpose | Reduce cost and modify density | Improve mechanical strength and durability |

| Common Materials | Carbon black, calcium carbonate, clay | Carbon black (high grade), silica, glass fibers |

| Effect on Rubber | Increases volume without enhancing strength significantly | Enhances tensile strength, abrasion resistance, elasticity |

| Loading Levels | High (up to 50-70% by weight) | Moderate (typically 10-30% by weight) |

| Cost Impact | Reduces overall cost of rubber compounds | Increases cost due to superior materials |

Introduction to Fillers and Reinforcements

Fillers are materials added to composites to improve specific properties like cost-efficiency, volume, or weight reduction without necessarily enhancing strength. Reinforcements are fibers or particles embedded within a matrix to significantly increase mechanical properties such as tensile strength, stiffness, and impact resistance. Both fillers and reinforcements play critical roles in composite material design, optimizing performance based on application requirements.

Defining Fillers: Composition and Functions

Fillers are typically composed of fine mineral powders such as calcium carbonate, talc, or silica, which are added to materials like plastics, rubber, and paper to improve physical properties and reduce production costs. Their primary functions include enhancing surface smoothness, increasing bulk, improving mechanical properties, and acting as processing aids to facilitate manufacturing. Unlike reinforcements, fillers do not significantly increase the strength or stiffness of the material but optimize its overall performance and economic efficiency.

Understanding Reinforcements: Roles and Types

Reinforcements play a crucial role in enhancing material strength and durability by improving mechanical properties such as tensile strength, impact resistance, and stiffness. Common types include fibers (glass, carbon, aramid), particles (ceramics, metals), and whiskers, each tailored to specific applications for composite materials. Your selection of reinforcements depends on desired performance characteristics, environmental conditions, and weight considerations in the final product.

Key Differences Between Fillers and Reinforcements

Fillers are materials added to composites primarily to reduce cost and improve properties like density, thermal stability, or surface finish, whereas reinforcements provide structural strength and rigidity by enhancing mechanical properties such as tensile strength and impact resistance. Fillers typically include substances like calcium carbonate, talc, or silica, which do not significantly increase load-bearing capacity, while reinforcements involve fibers such as glass, carbon, or aramid, designed to bear loads and improve durability. The key difference lies in function: fillers modify bulk or ancillary properties without substantial strength enhancement, whereas reinforcements are integral to the composite's mechanical performance.

Material Properties Impacted by Fillers

Fillers significantly influence material properties such as mechanical strength, stiffness, and thermal stability by altering the polymer matrix's behavior. Common fillers like calcium carbonate and silica enhance dimensional stability and reduce shrinkage, whereas reinforcing agents like carbon fibers primarily increase tensile strength and impact resistance. The distribution, size, and surface treatment of fillers determine their effectiveness in improving abrasion resistance, electrical conductivity, and overall durability of composite materials.

Mechanical Advantages of Reinforcements

Reinforcements significantly enhance mechanical properties such as tensile strength, stiffness, and impact resistance in composite materials compared to fillers. Unlike fillers that primarily occupy space and reduce cost, reinforcements improve load-bearing capacity and durability by forming a strong bond with the matrix. Your choice of reinforcement type directly influences the mechanical performance and longevity of the final product.

Common Applications for Fillers in Industry

Fillers are extensively used in industries such as plastics, rubber, paints, and adhesives to improve mechanical properties, reduce costs, and enhance product performance. Common fillers include calcium carbonate, talc, and silica, which help increase volume and impact resistance without significantly altering the material's intrinsic characteristics. These fillers also contribute to improved thermal stability, electrical insulation, and surface finish quality in manufactured goods.

Reinforcement Materials Used in Composites

Reinforcement materials in composites are primarily fibers such as glass, carbon, and aramid, which significantly enhance mechanical strength, stiffness, and durability. These materials provide structural support by creating a load-bearing network within the composite matrix, making them essential for high-performance applications in aerospace, automotive, and construction industries. Your choice of reinforcement influences the composite's weight, impact resistance, and thermal stability, ensuring the final product meets specific engineering requirements.

Cost, Performance, and Selection Criteria

Fillers generally reduce the overall cost of composites by occupying volume with inexpensive materials, while reinforcements enhance mechanical performance by providing strength and stiffness. Selection criteria depend largely on the desired balance between cost-efficiency and performance requirements, with fillers ideal for weight reduction and cost savings, and reinforcements chosen for structural integrity. Your decision should consider factors such as load-bearing needs, environmental exposure, and budget constraints to optimize material performance and cost-effectiveness.

Future Trends in Filler and Reinforcement Technologies

Future trends in filler and reinforcement technologies emphasize the development of nanomaterials such as carbon nanotubes and graphene to enhance composite strength and durability. Innovations include bio-based and sustainable fillers that reduce environmental impact while maintaining high performance. Advanced manufacturing techniques like additive manufacturing enable precise dispersion of reinforcement materials, optimizing mechanical and thermal properties in various industries.

Filler vs Reinforcement Infographic

libmatt.com

libmatt.com