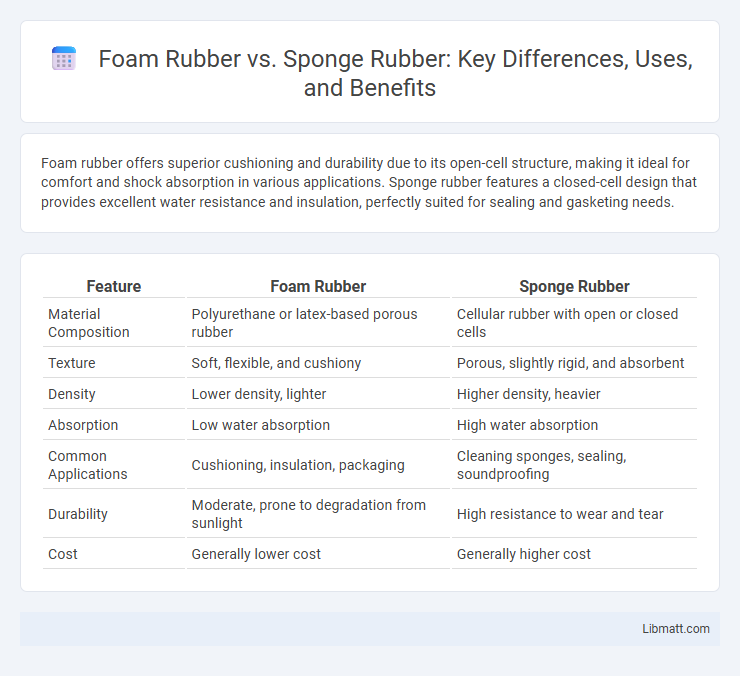

Foam rubber offers superior cushioning and durability due to its open-cell structure, making it ideal for comfort and shock absorption in various applications. Sponge rubber features a closed-cell design that provides excellent water resistance and insulation, perfectly suited for sealing and gasketing needs.

Table of Comparison

| Feature | Foam Rubber | Sponge Rubber |

|---|---|---|

| Material Composition | Polyurethane or latex-based porous rubber | Cellular rubber with open or closed cells |

| Texture | Soft, flexible, and cushiony | Porous, slightly rigid, and absorbent |

| Density | Lower density, lighter | Higher density, heavier |

| Absorption | Low water absorption | High water absorption |

| Common Applications | Cushioning, insulation, packaging | Cleaning sponges, sealing, soundproofing |

| Durability | Moderate, prone to degradation from sunlight | High resistance to wear and tear |

| Cost | Generally lower cost | Generally higher cost |

Introduction to Foam Rubber and Sponge Rubber

Foam rubber and sponge rubber are both flexible, porous materials used in cushioning and insulation applications, but they differ in their structure and properties. Foam rubber typically consists of synthetic polymers like polyurethane, featuring a closed-cell structure that provides higher durability and water resistance. Sponge rubber, often made from natural or synthetic latex, has an open-cell structure, resulting in greater breathability and softness suitable for absorption and padding.

Composition and Manufacturing Processes

Foam rubber consists of a polymer matrix with gas bubbles introduced during polymerization, typically made from polyurethane or latex, while sponge rubber is a type of foam rubber with an open-cell structure created by vulcanizing and expanding natural or synthetic rubber. Foam rubber manufacturing involves chemical foaming agents or physical processes like gas injection to create cellular structures, whereas sponge rubber undergoes a curing process with sulfur and accelerators, resulting in a porous, flexible material. The difference in composition and manufacturing affects the mechanical properties, density, and application suitability of both materials, with foam rubber having a more controlled cell structure and sponge rubber offering greater elasticity and resilience.

Key Physical Characteristics

Foam rubber is a lightweight, porous material known for its open-cell structure that provides excellent cushioning and breathability, making it highly resilient and flexible. Sponge rubber, on the other hand, features a closed-cell construction that offers superior water resistance and durability, ideal for sealing and insulation purposes. Your choice between foam rubber and sponge rubber should consider these physical characteristics to match the specific requirements of cushioning, shock absorption, or moisture resistance in your application.

Common Applications and Uses

Foam rubber is widely used in cushioning for furniture, mattresses, and automotive seating due to its excellent shock absorption and flexibility. Sponge rubber finds common applications in seals, gaskets, and insulation where its compressibility and resistance to water and chemicals are essential. Your choice between foam rubber and sponge rubber should depend on the specific requirements of durability, moisture resistance, and comfort in the intended application.

Durability and Longevity Comparison

Foam rubber exhibits greater durability and longevity compared to sponge rubber due to its closed-cell structure, which resists moisture, compression, and wear over time. Sponge rubber, characterized by its open-cell design, tends to absorb water and degrades faster under continuous stress or exposure to elements. For applications requiring extended lifespan and resistance to environmental factors, foam rubber is generally the superior choice.

Comfort and Cushioning Properties

Foam rubber offers superior comfort and cushioning properties due to its open-cell structure, which provides excellent elasticity and breathability, making it ideal for prolonged use in seating and mattresses. Sponge rubber, characterized by its closed-cell configuration, delivers firmer support and better shock absorption but with less airflow, making it suitable for applications requiring durability and water resistance. Understanding the differences in these materials helps you choose the best cushioning solution tailored to your comfort needs.

Resistance to Moisture and Chemicals

Foam rubber offers superior resistance to moisture and chemicals, making it ideal for applications exposed to water or harsh substances, while sponge rubber tends to absorb moisture more readily, reducing its durability in wet environments. The closed-cell structure of foam rubber minimizes water absorption and chemical penetration, enhancing longevity in industrial and automotive settings. You should choose foam rubber when resistance to environmental factors is critical for performance and durability.

Cost Effectiveness and Affordability

Foam rubber offers greater cost effectiveness due to its lightweight structure and efficient manufacturing process, making it more affordable for large-scale applications. Sponge rubber, while slightly more expensive, provides superior durability and resilience, justifying its higher price for projects requiring long-term performance. When choosing between them, you should consider your budget constraints alongside the specific functional demands of your application.

Environmental Impact and Sustainability

Foam rubber typically relies on synthetic materials derived from petroleum, resulting in a higher environmental footprint compared to sponge rubber, which often uses natural latex sourced from rubber trees and offers better biodegradability. Sponge rubber's sustainable harvesting practices contribute to reduced deforestation and lower carbon emissions, making it a more eco-friendly choice for your projects. Choosing sponge rubber enhances sustainability by promoting renewable resources and minimizing long-term waste accumulation.

Choosing the Right Material for Your Needs

Foam rubber offers superior cushioning, flexibility, and resilience, making it ideal for applications requiring shock absorption and comfort, such as upholstery and mattress production. Sponge rubber provides excellent water resistance and durability, suited for sealing, insulation, and automotive uses where moisture and wear resistance are critical. Selecting between foam rubber and sponge rubber depends on factors like environmental exposure, required elasticity, and specific functional demands to ensure optimal performance and longevity.

Foam Rubber vs Sponge Rubber Infographic

libmatt.com

libmatt.com