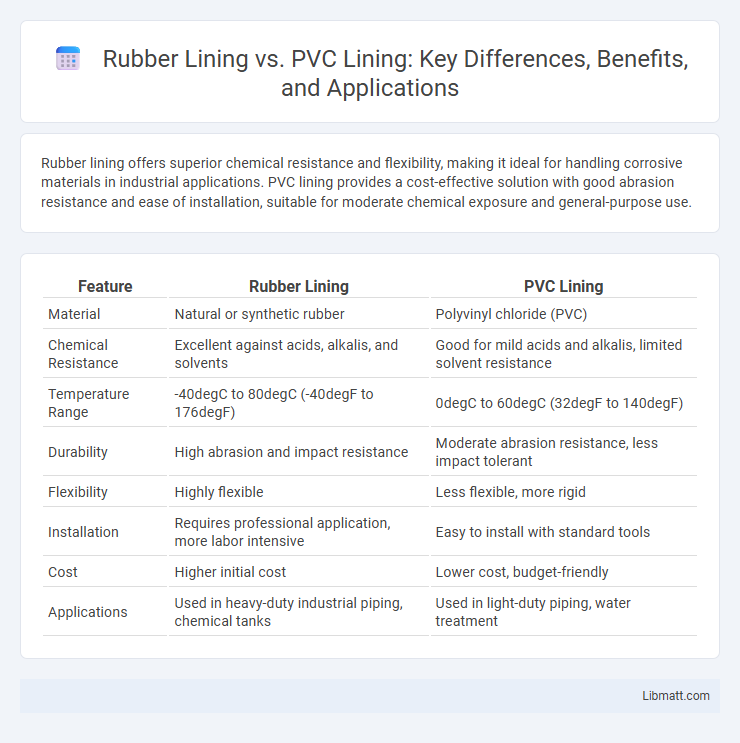

Rubber lining offers superior chemical resistance and flexibility, making it ideal for handling corrosive materials in industrial applications. PVC lining provides a cost-effective solution with good abrasion resistance and ease of installation, suitable for moderate chemical exposure and general-purpose use.

Table of Comparison

| Feature | Rubber Lining | PVC Lining |

|---|---|---|

| Material | Natural or synthetic rubber | Polyvinyl chloride (PVC) |

| Chemical Resistance | Excellent against acids, alkalis, and solvents | Good for mild acids and alkalis, limited solvent resistance |

| Temperature Range | -40degC to 80degC (-40degF to 176degF) | 0degC to 60degC (32degF to 140degF) |

| Durability | High abrasion and impact resistance | Moderate abrasion resistance, less impact tolerant |

| Flexibility | Highly flexible | Less flexible, more rigid |

| Installation | Requires professional application, more labor intensive | Easy to install with standard tools |

| Cost | Higher initial cost | Lower cost, budget-friendly |

| Applications | Used in heavy-duty industrial piping, chemical tanks | Used in light-duty piping, water treatment |

Introduction to Rubber and PVC Lining

Rubber lining provides superior resistance to abrasion, corrosion, and chemical exposure, making it ideal for industrial applications involving harsh chemicals or slurry handling. PVC lining offers excellent chemical resistance, lightweight properties, and cost-effectiveness, suitable for less aggressive environments like water treatment and chemical processing. Both materials enhance the longevity of pipes and tanks by protecting metal surfaces from damage caused by aggressive fluids.

Key Differences Between Rubber and PVC Linings

Rubber lining offers superior chemical resistance and flexibility, making it ideal for handling corrosive materials in aggressive environments, whereas PVC lining provides excellent abrasion resistance and is more cost-effective for less demanding applications. Rubber linings typically withstand higher temperatures and a broader range of chemicals, while PVC linings excel in environments requiring lightweight, UV-resistant solutions. The choice between rubber and PVC linings depends on specific operational conditions such as temperature, chemical exposure, and mechanical wear.

Material Composition and Properties

Rubber lining consists of natural or synthetic elastomers known for high flexibility, excellent abrasion resistance, and strong chemical inertness, making it ideal for impact-prone, corrosive environments. PVC lining, made from polyvinyl chloride, offers superior rigidity, good chemical resistance to acids and alkalis, and is lightweight, which is suitable for applications requiring structural support and corrosion prevention. Understanding the distinct material properties helps you select the optimal lining for specific industrial conditions, balancing durability and chemical compatibility.

Durability and Lifespan Comparison

Rubber lining offers superior durability and resistance to abrasion, chemicals, and temperature variations, which extends its lifespan significantly in harsh industrial environments. PVC lining provides good chemical resistance but tends to degrade faster under UV exposure and extreme temperatures, resulting in a shorter operational lifespan. Choosing rubber lining over PVC lining is advantageous for applications demanding long-term durability and minimal maintenance.

Chemical and Abrasion Resistance

Rubber lining offers superior abrasion resistance and excellent chemical resistance against acids, alkalis, and solvents, making it ideal for harsh industrial applications involving slurry and corrosive fluids. PVC lining provides good chemical resistance to a wide range of diluted acids and alkalis but has lower abrasion resistance compared to rubber, limiting its use in high-wear environments. Selecting between rubber and PVC linings depends on exposure to aggressive chemicals and the level of mechanical wear expected in the application.

Installation Process and Flexibility

Rubber lining offers a straightforward installation process that involves vulcanization, creating a seamless and durable protective layer ideal for irregular surfaces, while PVC lining involves welding sheets together, requiring precise handling to ensure airtight seams. Rubber lining provides exceptional flexibility and elasticity, accommodating dynamic movements and thermal expansion without cracking, whereas PVC lining is less flexible, making it more suitable for static applications with limited deformation. The choice between rubber and PVC lining often depends on the need for flexibility versus installation complexity in industrial corrosion protection.

Cost Analysis: Rubber vs PVC Lining

Rubber lining generally involves higher initial costs due to material and installation complexities, but offers superior durability and chemical resistance, which can reduce maintenance expenses over time. PVC lining tends to have lower upfront costs and easier installation, making it a budget-friendly option for less aggressive environments. Evaluating your specific application and total lifecycle costs will help determine whether the upfront investment in rubber lining or the cost-efficiency of PVC lining best suits your needs.

Common Applications and Industries

Rubber lining is extensively used in industries such as mining, chemical processing, and wastewater treatment for its superior resistance to abrasion, corrosion, and chemical attack. PVC lining finds common applications in food processing, water distribution, and pharmaceutical industries due to its cost-effectiveness, lightweight nature, and excellent resistance to acids and alkalis. Both materials are integral in protecting pipes, tanks, and vessels, with rubber lining preferred for heavy-duty environments and PVC lining suited for less aggressive conditions requiring chemical resistance.

Environmental Impact and Sustainability

Rubber lining offers superior durability and resistance to chemicals, extending the lifespan of equipment and reducing waste compared to PVC lining, which is less durable and often replaced more frequently. PVC lining production involves higher greenhouse gas emissions and uses non-renewable resources, making it less environmentally friendly than rubber alternatives derived from natural or recycled materials. Choosing rubber lining for your industrial applications supports sustainability by minimizing environmental impact through longer service life and reduced chemical pollution.

Choosing the Right Lining for Your Needs

Rubber lining offers superior chemical resistance and durability for handling corrosive materials, making it ideal for aggressive industrial applications, while PVC lining provides excellent cost-effectiveness and ease of installation in less demanding environments. Selecting the right lining depends on factors such as chemical exposure, temperature range, mechanical wear, and budget constraints. Evaluating these criteria ensures optimal performance, longevity, and protection for tanks, pipes, and processing equipment.

Rubber Lining vs PVC Lining Infographic

libmatt.com

libmatt.com