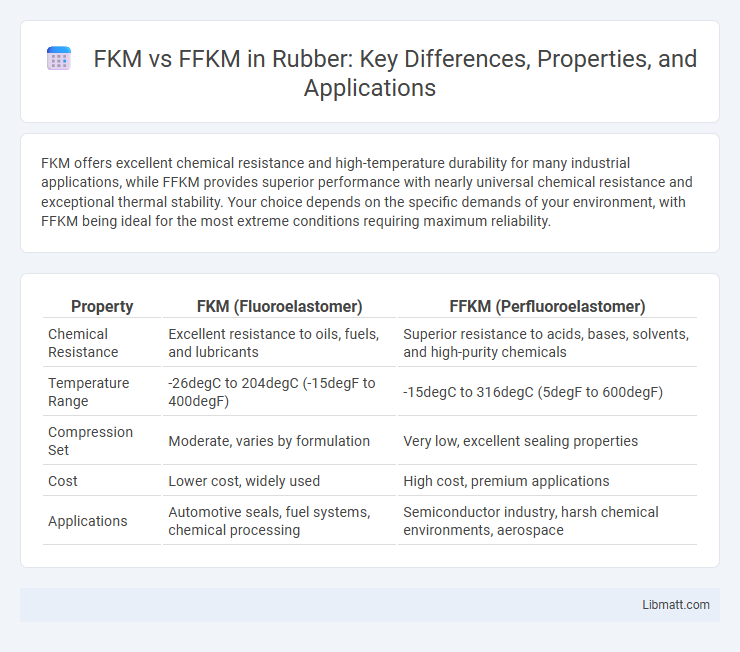

FKM offers excellent chemical resistance and high-temperature durability for many industrial applications, while FFKM provides superior performance with nearly universal chemical resistance and exceptional thermal stability. Your choice depends on the specific demands of your environment, with FFKM being ideal for the most extreme conditions requiring maximum reliability.

Table of Comparison

| Property | FKM (Fluoroelastomer) | FFKM (Perfluoroelastomer) |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, and lubricants | Superior resistance to acids, bases, solvents, and high-purity chemicals |

| Temperature Range | -26degC to 204degC (-15degF to 400degF) | -15degC to 316degC (5degF to 600degF) |

| Compression Set | Moderate, varies by formulation | Very low, excellent sealing properties |

| Cost | Lower cost, widely used | High cost, premium applications |

| Applications | Automotive seals, fuel systems, chemical processing | Semiconductor industry, harsh chemical environments, aerospace |

Introduction to FKM and FFKM

FKM (fluoroelastomers) are high-performance synthetic rubber materials known for exceptional chemical resistance, high temperature tolerance up to 200degC, and durability in harsh environments. FFKM (perfluoroelastomers) provide enhanced chemical and thermal stability, functioning reliably at temperatures exceeding 300degC and resisting aggressive fluids where FKM may degrade. Selecting FFKM over FKM ensures your sealing applications endure extreme conditions with superior longevity and safety.

Chemical Composition and Structure

FKM is a fluoroelastomer primarily composed of vinylidene fluoride (VDF) and hexafluoropropylene (HFP), providing excellent resistance to oils and fuels through a semi-crystalline structure. FFKM, a perfluoroelastomer, consists of fully fluorinated monomers such as tetrafluoroethylene (TFE) and propylene, offering superior chemical resistance due to its perfluorinated backbone and amorphous structure. Your choice depends on operating environments, with FFKM excelling in aggressive chemical exposure where FKM may degrade.

Key Performance Differences

FKM (Fluorocarbon) offers excellent chemical resistance and high-temperature stability up to 250degC, making it suitable for automotive and industrial applications. FFKM (Perfluoroelastomer) surpasses FKM with superior chemical inertness, resistance to aggressive solvents, and thermal stability that can reach 327degC, ideal for semiconductor and pharmaceutical industries. Your choice between FKM and FFKM depends on the specific environmental conditions and performance requirements of your application.

Temperature Resistance Comparison

FKM elastomers typically offer temperature resistance ranging from -20degC to 204degC, making them suitable for a wide range of industrial applications. FFKM materials, however, exhibit superior thermal stability withstanding continuous exposure up to 327degC and short-term spikes even higher, ideal for extreme environments like semiconductor manufacturing. This significant temperature resistance difference makes FFKM the preferred choice for high-performance sealing solutions requiring exceptional heat tolerance.

Chemical Compatibility of FKM and FFKM

FKM and FFKM differ significantly in chemical compatibility, with FFKM offering superior resistance to aggressive chemicals, high temperatures, and steam compared to FKM. FFKM seals can withstand a broader range of harsh chemicals, including strong acids, bases, and solvents, making them ideal for demanding industrial applications. Choosing FFKM over FKM enhances your system's durability and reliability when exposed to extreme chemical environments.

Typical Applications for FKM

FKM, commonly known as Viton, is widely used in automotive fuel systems, seals, and gaskets due to its excellent resistance to fuels, oils, and high temperatures up to 200degC. Typical applications include O-rings, valve seals, and gaskets where chemical stability and durability against hydrocarbons are essential. Your choice of FKM ensures reliable performance in environments involving aggressive chemicals and elevated temperatures.

Typical Applications for FFKM

FFKM, also known as perfluoroelastomer, is ideal for extreme chemical, high-temperature, and aggressive environment seals in industries like semiconductor manufacturing, chemical processing, and aerospace. Its exceptional resistance to acids, bases, and solvents makes it suitable for applications such as valve seals, O-rings, and gaskets in harsh process conditions. You should choose FFKM when superior chemical compatibility and durability are critical for long-term performance.

Cost Considerations: FKM vs FFKM

FKM materials typically offer a more cost-effective solution for applications requiring good chemical resistance and temperature tolerance, making them suitable for a wide range of industrial uses. FFKM, known for its superior chemical stability and extreme high-temperature performance, carries a significantly higher price point that reflects its advanced properties and longer lifespan in harsh environments. When selecting between FKM and FFKM, your decision should weigh initial expenditure against long-term durability and performance needs to ensure cost efficiency.

Longevity and Maintenance Requirements

FKM offers excellent chemical resistance and durability suitable for many industrial applications, but FFKM provides superior longevity by withstanding extreme temperatures and aggressive chemicals with minimal degradation. Your maintenance requirements decrease significantly with FFKM seals due to their exceptional resistance to harsh environments, reducing downtime and replacement frequency. Choosing FFKM over FKM enhances operational efficiency and lowers long-term costs in demanding conditions.

How to Choose Between FKM and FFKM

Choosing between FKM and FFKM depends on chemical resistance requirements, temperature range, and budget constraints. FKM offers excellent resistance to oils, fuels, and moderate chemicals at temperatures up to 200degC, making it suitable for general industrial applications. FFKM provides superior chemical resistance and extreme temperature tolerance up to 327degC, ideal for highly aggressive environments and critical sealing applications despite higher costs.

FKM vs FFKM Infographic

libmatt.com

libmatt.com