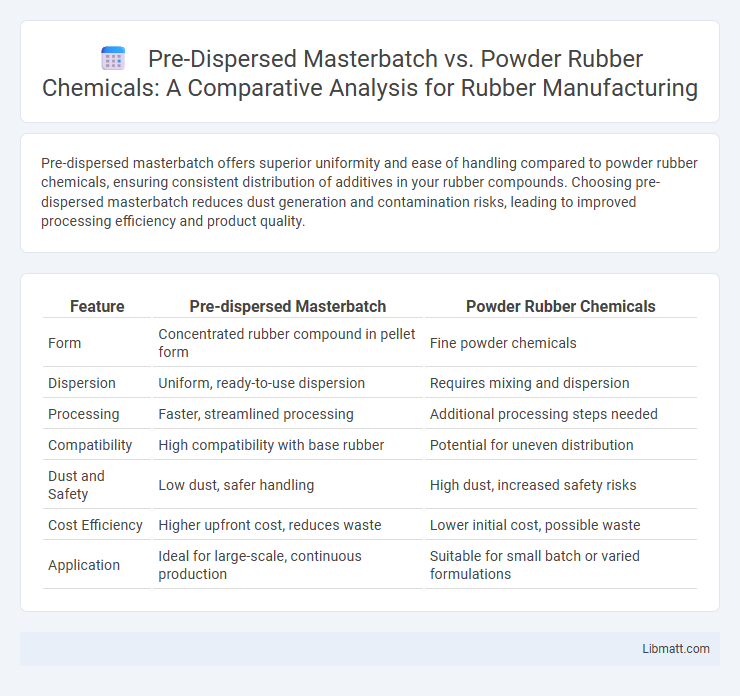

Pre-dispersed masterbatch offers superior uniformity and ease of handling compared to powder rubber chemicals, ensuring consistent distribution of additives in your rubber compounds. Choosing pre-dispersed masterbatch reduces dust generation and contamination risks, leading to improved processing efficiency and product quality.

Table of Comparison

| Feature | Pre-dispersed Masterbatch | Powder Rubber Chemicals |

|---|---|---|

| Form | Concentrated rubber compound in pellet form | Fine powder chemicals |

| Dispersion | Uniform, ready-to-use dispersion | Requires mixing and dispersion |

| Processing | Faster, streamlined processing | Additional processing steps needed |

| Compatibility | High compatibility with base rubber | Potential for uneven distribution |

| Dust and Safety | Low dust, safer handling | High dust, increased safety risks |

| Cost Efficiency | Higher upfront cost, reduces waste | Lower initial cost, possible waste |

| Application | Ideal for large-scale, continuous production | Suitable for small batch or varied formulations |

Introduction to Rubber Compound Additives

Rubber compound additives enhance the performance and processing of rubber by improving properties such as elasticity, durability, and resistance to heat and chemicals. Pre-dispersed masterbatch involves incorporating finely distributed chemicals within a carrier resin, ensuring uniform dispersion and improved mixing efficiency compared to conventional powder rubber chemicals. This uniform distribution minimizes agglomeration issues and enhances the overall quality and consistency of the rubber compound.

What Are Pre-dispersed Masterbatches?

Pre-dispersed masterbatches are concentrated rubber chemical formulations evenly distributed within a carrier resin, allowing for improved dispersion and consistent performance in rubber processing. These masterbatches simplify the mixing process by reducing dust generation and enhancing the uniformity of additive incorporation compared to powder rubber chemicals. Commonly used in tire manufacturing and rubber goods production, they contribute to improved product quality and processing efficiency.

Understanding Powder Rubber Chemicals

Powder rubber chemicals are finely ground formulations used to improve the vulcanization process, offering precise control over chemical dispersion in rubber compounds. These dry powders provide cost-effective handling and uniform distribution but may require additional mixing steps compared to pre-dispersed masterbatch. Your choice depends on the application's need for processing efficiency and compound consistency.

Key Differences Between Pre-dispersed Masterbatch and Powder Chemicals

Pre-dispersed masterbatch offers superior dispersion uniformity compared to powder rubber chemicals, enhancing processing efficiency and product consistency in rubber compounding. Unlike powders, pre-dispersed masterbatches contain chemicals already evenly distributed on a carrier, minimizing dust generation and improving handling safety. The controlled particle size and composition in masterbatches reduce mixing time and energy consumption, leading to improved overall production performance.

Advantages of Using Pre-dispersed Masterbatch

Pre-dispersed Masterbatch offers superior dispersion of rubber chemicals, ensuring uniform distribution and enhanced process efficiency compared to powder forms. It reduces dust generation, minimizing health hazards and improving workplace safety, while also enabling easier handling and dosing accuracy during rubber compounding. Your production process benefits from consistent product quality and reduced downtime, resulting in cost savings and optimized manufacturing performance.

Drawbacks of Powder Rubber Chemicals

Powder rubber chemicals suffer from poor dispersion, leading to inconsistent distribution in the rubber matrix and reduced performance. Handling difficulties, including dust generation and health hazards, pose significant risks during processing. Moreover, powder forms often result in longer mixing times and higher energy consumption compared to pre-dispersed masterbatch solutions.

Impact on Rubber Processing Efficiency

Pre-dispersed masterbatch enhances rubber processing efficiency by ensuring uniform distribution of additives, reducing mixing time and energy consumption compared to powder rubber chemicals. The improved dispersion minimizes agglomeration and improves compound consistency, leading to better product quality and throughput. Powder forms often require longer dispersion periods and can cause processing delays due to uneven distribution and dust generation.

Safety and Environmental Considerations

Pre-dispersed masterbatch offers enhanced safety by minimizing dust generation, reducing inhalation risks compared to powder rubber chemicals, which pose higher respiratory hazards during handling. Environmentally, masterbatches lower contamination potential and waste production since their concentrated form ensures precise dosing and less material loss. The solid, uniform nature of masterbatches also facilitates safer storage and transportation, contributing to improved workplace and environmental sustainability.

Cost Implications in Rubber Manufacturing

Pre-dispersed masterbatch typically reduces costs in rubber manufacturing by improving dispersion quality, which minimizes waste and enhances processing efficiency compared to powder rubber chemicals. Powder forms often require longer mixing times and higher energy consumption, increasing operational expenses and labor costs. Choosing pre-dispersed masterbatch can optimize your production budget by lowering material losses and improving overall product consistency.

Choosing the Right Additive for Your Application

Pre-dispersed masterbatch offers superior dispersion and ease of handling compared to powder rubber chemicals, reducing contamination risks and ensuring consistent additive distribution in your rubber compounding process. Powder rubber chemicals may provide cost advantages and flexibility in dosage adjustments but require thorough mixing to avoid agglomeration and uneven performance. Selecting the right additive depends on your application's need for process efficiency, mixing equipment, and desired product quality.

Pre-dispersed Masterbatch vs Powder Rubber Chemicals Infographic

libmatt.com

libmatt.com