Tire wire provides structural strength and flexibility to the tire's body, while bead wire reinforces the tire's bead area, ensuring a secure fit on the rim and preventing slippage. Understanding the difference between tire wire and bead wire helps you maintain proper tire performance and safety.

Table of Comparison

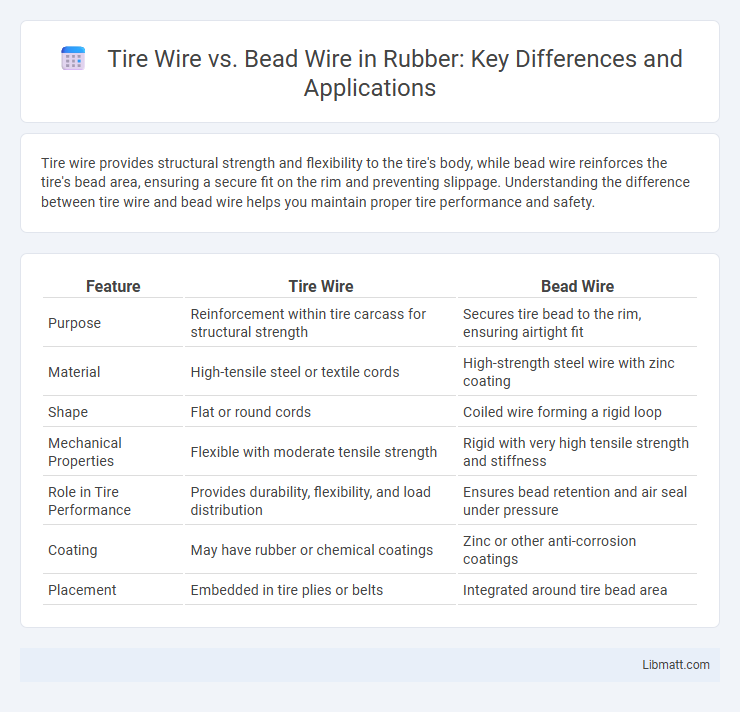

| Feature | Tire Wire | Bead Wire |

|---|---|---|

| Purpose | Reinforcement within tire carcass for structural strength | Secures tire bead to the rim, ensuring airtight fit |

| Material | High-tensile steel or textile cords | High-strength steel wire with zinc coating |

| Shape | Flat or round cords | Coiled wire forming a rigid loop |

| Mechanical Properties | Flexible with moderate tensile strength | Rigid with very high tensile strength and stiffness |

| Role in Tire Performance | Provides durability, flexibility, and load distribution | Ensures bead retention and air seal under pressure |

| Coating | May have rubber or chemical coatings | Zinc or other anti-corrosion coatings |

| Placement | Embedded in tire plies or belts | Integrated around tire bead area |

Introduction to Tire Wire and Bead Wire

Tire wire and bead wire are essential components in tire manufacturing, providing structural integrity and durability. Tire wire is primarily used for reinforcing the tire body, offering flexibility and strength to withstand road stresses, while bead wire is specifically designed to secure the tire to the rim, ensuring a tight fit and maintaining the tire's shape. Understanding the distinct roles of these wires helps you choose the right material for enhanced tire performance and safety.

What is Tire Wire?

Tire wire is a high-tensile steel wire used primarily in the reinforcement of tires, providing strength and durability to withstand road stress. It serves as the main component in tire cord fabric, which forms the tire's carcass, enhancing its structural integrity and resistance to deformation. Unlike bead wire, tire wire is designed to offer flexibility and tensile strength within the tire body rather than just securing the tire to the rim.

What is Bead Wire?

Bead wire is a specialized steel wire used to reinforce the bead area of a tire, ensuring a secure fit between the tire and the rim. It features a high tensile strength and corrosion resistance to withstand the stresses and maintain the tire's shape during use. Your choice of bead wire impacts the tire's durability, safety, and overall performance on the road.

Key Differences Between Tire Wire and Bead Wire

Tire wire and bead wire serve distinct functions in tire construction, with tire wire primarily providing structural reinforcement to the tire's body and enhancing its overall strength and durability. Bead wire specifically secures the tire to the rim by forming a strong hoop that grips the wheel, ensuring a proper seal and preventing slippage during operation. The key differences between tire wire and bead wire lie in their placement, mechanical properties, and roles within the tire, with tire wire emphasizing flexibility and tensile strength, while bead wire focuses on rigidity and resilience to maintain the tire's shape and attachment.

Material Composition: Tire Wire vs Bead Wire

Tire wire is typically made from high-tensile steel with a zinc coating to enhance rust resistance, providing strength and durability for the tire's structural support. Bead wire, on the other hand, features a higher carbon content in its steel composition, offering greater tensile strength and flexibility crucial for securing the tire bead to the rim. Understanding the material differences in tire wire vs bead wire helps ensure your tires maintain optimal performance and safety.

Manufacturing Processes Compared

Tire wire manufacturing involves cold drawing high-carbon steel into fine, flexible strands designed to provide strength and flexibility within tire carcasses. Bead wire production requires drawing and hardening steel wire to create rigid, reinforced loops that secure the tire to the rim, ensuring a tight fit and durability. Your choice between tire wire and bead wire depends on the specific mechanical requirements and manufacturing processes tailored to optimize tire performance and safety.

Common Applications: Tire Wire vs Bead Wire

Tire wire is commonly used as a reinforcement material in the carcass and sidewalls of tires, providing strength and flexibility to withstand road stresses and impacts. Bead wire is primarily utilized in the bead area of tires, securing the tire to the rim and maintaining an airtight seal under high pressure. Both wires are essential in tire manufacturing, with tire wire focusing on structural integrity and bead wire ensuring proper fit and durability.

Performance and Durability Factors

Tire wire offers superior tensile strength and flexibility essential for enhancing overall tire performance, especially in radial and bias-ply tires. Bead wire provides exceptional hardness and stiffness, crucial for maintaining a secure fit between the tire and wheel rim, directly impacting durability under high-stress conditions. The performance of tire wire emphasizes impact resistance and fatigue life, while bead wire's durability hinges on corrosion resistance and dimensional stability to ensure long-term reliability.

Advantages and Disadvantages of Each Wire Type

Tire wire offers superior tensile strength and flexibility, making it ideal for reinforcing heavy-duty tires but tends to increase manufacturing costs due to its higher material quality. Bead wire provides excellent bending resistance and ensures a tight fit between the tire and rim, which enhances safety and ride stability; however, it may suffer from corrosion issues if not properly coated. Selecting between tire wire and bead wire depends on application-specific requirements such as load capacity, durability, and environmental exposure.

Choosing the Right Wire for Your Needs

Tire wire and bead wire serve distinct functions in tire manufacturing; tire wire provides structural strength within the carcass, while bead wire secures the tire onto the wheel rim. Choosing the right wire depends on your tire's application--high-strength bead wire ensures a secure fit for safety, whereas durable tire wire enhances overall tire longevity and performance. Understanding these differences helps you select the optimal wire for your specific tire requirements.

Tire Wire vs Bead Wire Infographic

libmatt.com

libmatt.com