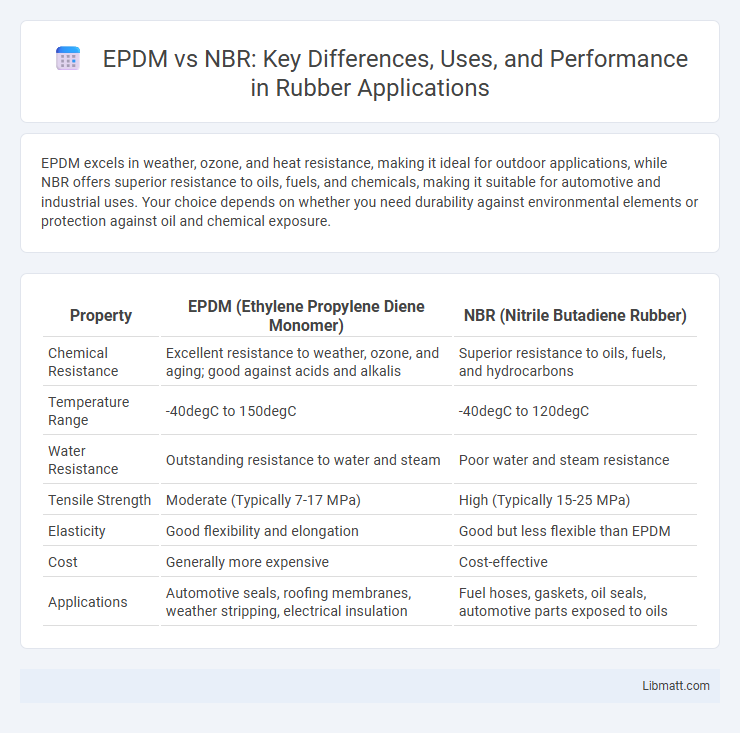

EPDM excels in weather, ozone, and heat resistance, making it ideal for outdoor applications, while NBR offers superior resistance to oils, fuels, and chemicals, making it suitable for automotive and industrial uses. Your choice depends on whether you need durability against environmental elements or protection against oil and chemical exposure.

Table of Comparison

| Property | EPDM (Ethylene Propylene Diene Monomer) | NBR (Nitrile Butadiene Rubber) |

|---|---|---|

| Chemical Resistance | Excellent resistance to weather, ozone, and aging; good against acids and alkalis | Superior resistance to oils, fuels, and hydrocarbons |

| Temperature Range | -40degC to 150degC | -40degC to 120degC |

| Water Resistance | Outstanding resistance to water and steam | Poor water and steam resistance |

| Tensile Strength | Moderate (Typically 7-17 MPa) | High (Typically 15-25 MPa) |

| Elasticity | Good flexibility and elongation | Good but less flexible than EPDM |

| Cost | Generally more expensive | Cost-effective |

| Applications | Automotive seals, roofing membranes, weather stripping, electrical insulation | Fuel hoses, gaskets, oil seals, automotive parts exposed to oils |

Introduction to EPDM and NBR

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber known for its excellent resistance to weathering, ozone, and UV radiation, making it ideal for outdoor applications. NBR (Nitrile Butadiene Rubber) is a synthetic rubber primarily valued for its superior resistance to oils, fuels, and chemicals, widely used in automotive and industrial environments. Both EPDM and NBR offer distinct performance advantages depending on environmental exposure and chemical compatibility requirements.

Chemical Composition and Structure

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber composed primarily of ethylene, propylene, and a diene comonomer, giving it a saturated hydrocarbon backbone with unsaturated side chains that enhance vulcanization. NBR (Nitrile Butadiene Rubber) consists of copolymers of acrylonitrile and butadiene, featuring polar nitrile groups that provide superior resistance to oils and fuels. Your choice between EPDM and NBR depends on the desired chemical resistance and structural properties necessary for specific industrial applications.

Physical Properties Comparison

EPDM exhibits superior resistance to ozone, UV rays, and extreme weather, making it ideal for outdoor applications, while NBR offers excellent resistance to oils, fuels, and chemicals, suited for automotive and industrial uses. EPDM generally has better flexibility at low temperatures and higher tensile strength, whereas NBR provides higher abrasion resistance and better compression set characteristics. Both materials differ significantly in their chemical structure, impacting their performance in various physical environments.

Temperature Resistance

EPDM rubber offers superior temperature resistance, performing reliably in a range from -40degC to 150degC, making it suitable for high-heat applications such as automotive weatherstripping and steam hoses. NBR (Nitrile Butadiene Rubber) withstands temperatures typically between -30degC and 100degC, which limits its use in extreme heat environments but excels in oil and fuel resistance. When selecting materials for thermal stability, EPDM is preferred for exposure to high temperatures and weathering, while NBR is favored for moderate thermal conditions combined with chemical resistance.

Chemical Resistance

EPDM (Ethylene Propylene Diene Monomer) exhibits superior resistance to polar chemicals, ozone, and weathering, making it highly effective against acids, alkalis, and hot water exposure. NBR (Nitrile Butadiene Rubber) performs exceptionally well with petroleum-based oils, fuels, and non-polar solvents but degrades rapidly when exposed to ozone or weather conditions. Chemical resistance profiles dictate the selection of EPDM for outdoor and aqueous chemical applications, while NBR is favored in oil-based environments requiring strong hydrocarbon resistance.

Applications and Industries

EPDM excels in automotive weather seals, roofing membranes, and outdoor electrical insulation due to its superior UV and ozone resistance. NBR is preferred in fuel hoses, industrial gloves, and hydraulic seals thanks to its excellent oil and chemical resistance. Your choice between EPDM and NBR depends on whether exposure to harsh weather or oil-based substances is the primary concern in your industry application.

Durability and Longevity

EPDM rubber exhibits superior durability and longevity compared to NBR, particularly in outdoor applications due to its exceptional resistance to UV radiation, ozone, and weathering. NBR, while highly resistant to oils and fuels, tends to degrade faster under prolonged exposure to heat, sunlight, and atmospheric conditions. EPDM's exceptional thermal stability and weather resistance make it ideal for long-term use in automotive and roofing seals where extended service life is critical.

Cost Differences

EPDM typically costs more than NBR due to its superior weather, ozone, and heat resistance, making it ideal for outdoor and automotive applications. NBR is generally more affordable and excels in oil and fuel resistance, making it suitable for industrial seals and hoses where cost efficiency is essential. Your choice depends on balancing initial material investment with performance requirements in specific environments.

Environmental Impact and Sustainability

EPDM offers superior environmental benefits due to its excellent resistance to ozone, UV, and weathering, leading to longer product lifespans and reduced waste. NBR, while effective for oil resistance, typically has a higher carbon footprint owing to its petroleum-based composition and lower durability in outdoor conditions. Sustainable choices favor EPDM's recyclability and lower emissions during production, making it more eco-friendly compared to NBR.

Choosing Between EPDM and NBR

Choosing between EPDM and NBR depends on application-specific factors such as chemical resistance and temperature range. EPDM excels in outdoor environments with superior resistance to UV, ozone, and weathering, making it ideal for automotive seals and roofing membranes. NBR offers excellent resistance to oils, fuels, and solvents, favoring applications in fuel hoses, gaskets, and industrial seals where petroleum-based fluids are present.

EPDM vs NBR Infographic

libmatt.com

libmatt.com