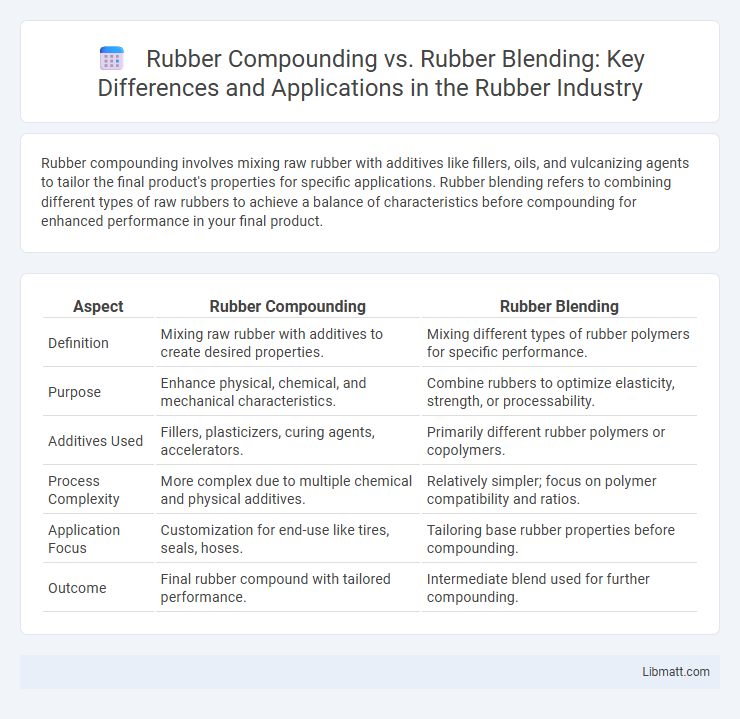

Rubber compounding involves mixing raw rubber with additives like fillers, oils, and vulcanizing agents to tailor the final product's properties for specific applications. Rubber blending refers to combining different types of raw rubbers to achieve a balance of characteristics before compounding for enhanced performance in your final product.

Table of Comparison

| Aspect | Rubber Compounding | Rubber Blending |

|---|---|---|

| Definition | Mixing raw rubber with additives to create desired properties. | Mixing different types of rubber polymers for specific performance. |

| Purpose | Enhance physical, chemical, and mechanical characteristics. | Combine rubbers to optimize elasticity, strength, or processability. |

| Additives Used | Fillers, plasticizers, curing agents, accelerators. | Primarily different rubber polymers or copolymers. |

| Process Complexity | More complex due to multiple chemical and physical additives. | Relatively simpler; focus on polymer compatibility and ratios. |

| Application Focus | Customization for end-use like tires, seals, hoses. | Tailoring base rubber properties before compounding. |

| Outcome | Final rubber compound with tailored performance. | Intermediate blend used for further compounding. |

Introduction to Rubber Compounding and Blending

Rubber compounding involves the precise formulation of raw rubber with additives like fillers, plasticizers, accelerators, and antioxidants to enhance physical properties and performance characteristics. Rubber blending focuses on the physical mixing of different types of rubbers to achieve specific mechanical properties and processability. Both processes are essential in the rubber industry for tailoring material properties to various applications such as automotive tires, industrial seals, and consumer products.

Defining Rubber Compounding

Rubber compounding involves the precise formulation and mixing of raw rubber with various additives such as fillers, accelerators, plasticizers, and curing agents to enhance its physical, chemical, and mechanical properties. This process is critical for tailoring rubber characteristics like elasticity, durability, and resistance to heat, chemicals, and abrasion, ensuring optimal performance for specific applications. Unlike rubber blending, which primarily combines different types of elastomers, compounding integrates functional ingredients to achieve a targeted balance of performance attributes.

What is Rubber Blending?

Rubber blending involves mixing different types of rubber polymers to create a tailor-made compound with enhanced performance characteristics such as improved elasticity, strength, and resistance to environmental factors. This process is essential in customizing materials for specific applications, ensuring that Your final product meets the required mechanical and chemical properties. Rubber blending differs from rubber compounding, which includes adding fillers, plasticizers, and other additives to modify the rubber's quality and functionality.

Key Differences Between Compounding and Blending

Rubber compounding involves the precise formulation of raw rubber with additives like fillers, plasticizers, accelerators, and curing agents to enhance specific mechanical and chemical properties, while rubber blending primarily entails physically mixing different types or grades of rubbers to achieve a balanced performance profile. Compounding requires a controlled process to ensure uniform distribution and compatibility of ingredients critical for vulcanization, whereas blending focuses on achieving homogeneity and optimizing the synergy between various rubber polymers. The key differences lie in the purpose and complexity: compounding modifies the raw material's characteristics for targeted applications, whereas blending combines multiple rubber materials to capitalize on their complementary properties.

Materials Used in Rubber Compounding

Rubber compounding involves the precise mixing of natural or synthetic rubber with fillers, plasticizers, curing agents, and antioxidants to tailor the final product's mechanical and chemical properties. Materials such as carbon black, silica, sulfur, and accelerators are commonly used to enhance durability, elasticity, and resistance to heat and chemicals. Your choice of specific compounds directly influences the performance and application of the rubber in industries ranging from automotive to consumer goods.

Techniques of Rubber Blending

Rubber blending techniques involve physically mixing different types of rubber to achieve specific properties such as improved elasticity, tensile strength, or resistance to environmental factors. Methods like mastication, internal mixing using Banbury mixers, and two-roll mill processing allow for uniform dispersion of fillers, chemicals, and rubber polymers in the blend. Your choice of rubber blending technique directly impacts the compatibility and performance of the final rubber compound in industrial applications.

Industrial Applications: Compounding vs Blending

Rubber compounding involves mixing raw rubber with additives such as fillers, plasticizers, and curing agents to achieve specific mechanical properties required in automotive tires, conveyor belts, and seals. Rubber blending combines different types of raw rubber to optimize elasticity, durability, and processing characteristics for industrial products like hoses, gaskets, and vibration dampers. The compounding process tailors performance attributes suited for heavy-duty applications, while blending focuses on material compatibility and cost efficiency for diverse manufacturing needs.

Performance and Properties Comparison

Rubber compounding involves mixing polymers with additives like fillers, curing agents, and plasticizers to enhance elasticity, tensile strength, and resistance to heat and wear, resulting in tailored performance for specific applications. Rubber blending combines different rubber types to achieve a balance of properties such as flexibility, durability, and chemical resistance, optimizing material behavior for diverse industrial uses. Understanding these differences helps you select the right process to meet your performance requirements and improve product lifespan.

Challenges and Limitations

Rubber compounding involves mixing raw rubber with additives to achieve specific properties, but challenges include controlling ingredient dispersion and maintaining consistent quality across batches. Rubber blending, the process of combining different rubber types, faces limitations like incompatibility between polymers and phase separation, which can reduce overall material performance. Your choice between compounding and blending must consider these issues to optimize the final product's mechanical strength and durability.

Future Trends in Rubber Processing

Future trends in rubber processing emphasize advanced rubber compounding techniques that enhance material properties through precise formulation of polymers, fillers, and additives to meet specific performance criteria. Innovations in rubber blending focus on achieving homogeneous mixtures with improved compatibility, enabling the development of sustainable and high-performance rubber composites for automotive and industrial applications. The integration of digital technologies and machine learning aids in optimizing compounding and blending processes, reducing waste and improving efficiency in rubber manufacturing.

Rubber compounding vs Rubber blending Infographic

libmatt.com

libmatt.com