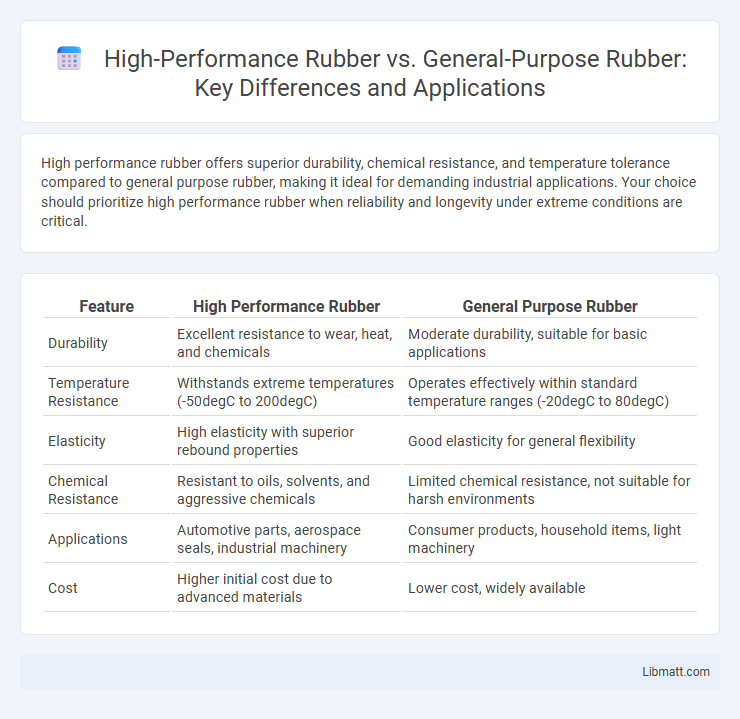

High performance rubber offers superior durability, chemical resistance, and temperature tolerance compared to general purpose rubber, making it ideal for demanding industrial applications. Your choice should prioritize high performance rubber when reliability and longevity under extreme conditions are critical.

Table of Comparison

| Feature | High Performance Rubber | General Purpose Rubber |

|---|---|---|

| Durability | Excellent resistance to wear, heat, and chemicals | Moderate durability, suitable for basic applications |

| Temperature Resistance | Withstands extreme temperatures (-50degC to 200degC) | Operates effectively within standard temperature ranges (-20degC to 80degC) |

| Elasticity | High elasticity with superior rebound properties | Good elasticity for general flexibility |

| Chemical Resistance | Resistant to oils, solvents, and aggressive chemicals | Limited chemical resistance, not suitable for harsh environments |

| Applications | Automotive parts, aerospace seals, industrial machinery | Consumer products, household items, light machinery |

| Cost | Higher initial cost due to advanced materials | Lower cost, widely available |

Introduction to Rubber Types

High performance rubber offers superior durability, heat resistance, and mechanical properties compared to general purpose rubber, making it ideal for demanding industrial applications. General purpose rubber serves well in everyday uses with moderate flexibility and resilience but may degrade faster under extreme conditions. Understanding the key differences helps you select the right rubber type to match your specific performance and environmental requirements.

Defining High Performance Rubber

High Performance Rubber refers to advanced elastomers engineered to offer superior resistance to extreme temperatures, chemicals, abrasion, and mechanical stress compared to General Purpose Rubber. These specialized rubbers often incorporate synthetic polymers such as fluoroelastomers, silicone, or fluorosilicone, providing enhanced durability and longevity in demanding industrial applications. High Performance Rubber is essential in sectors requiring reliable sealing, insulation, and vibration dampening where General Purpose Rubber materials typically fail.

Characteristics of General Purpose Rubber

General Purpose Rubber is known for its flexibility, moderate durability, and resistance to abrasion and weathering, making it suitable for everyday applications like seals, gaskets, and hoses. It offers good elasticity and tensile strength but lacks the enhanced temperature and chemical resistance found in High Performance Rubber. Your choice depends on whether basic performance and cost-effectiveness meet the requirements of your project.

Key Differences Between High Performance and General Purpose Rubber

High performance rubber exhibits superior properties such as enhanced temperature resistance, increased tensile strength, and excellent chemical stability compared to general purpose rubber, which is designed for more basic applications with moderate durability. High performance rubber is often used in extreme environments like automotive, aerospace, and industrial machinery, while general purpose rubber suits everyday items like seals, gaskets, and insulation. Your choice between these rubbers impacts product longevity, operational safety, and efficiency in demanding versus standard conditions.

Common Applications of High Performance Rubber

High performance rubber is commonly used in industries requiring superior resistance to extreme temperatures, chemicals, and mechanical stress, such as automotive, aerospace, and oil and gas sectors. Its applications include sealing solutions, gaskets, vibration dampening components, and hoses that must maintain integrity under severe conditions. Compared to general purpose rubber, high performance rubber ensures enhanced durability, longevity, and reliability in critical environments.

Typical Uses for General Purpose Rubber

General purpose rubber is commonly used in applications such as gaskets, seals, hoses, and automotive components due to its excellent flexibility and moderate resistance to wear and weathering. It is well-suited for consumer products, industrial equipment, and building materials where cost-effectiveness and versatility are priority factors. Typical materials include natural rubber (NR) and styrene-butadiene rubber (SBR), which provide sufficient durability for standard environmental conditions.

Performance Metrics: Durability, Flexibility, and Resistance

High Performance Rubber exhibits superior durability, flexing repeatedly without cracking or breaking, making it ideal for demanding environments. It also maintains exceptional flexibility across a wide temperature range, ensuring consistent performance where General Purpose Rubber may stiffen or degrade. Your choice of High Performance Rubber enhances resistance to abrasion, chemicals, and extreme conditions, significantly outperforming General Purpose Rubber in longevity and reliability.

Cost Comparison and Economic Considerations

High Performance Rubber typically incurs higher upfront costs due to advanced materials and engineering, but offers superior durability and resistance, reducing replacement and maintenance expenses over time. General Purpose Rubber is more affordable initially, making it suitable for low-stress applications where budget constraints are critical. Your choice depends on balancing immediate budget limits against long-term savings and performance requirements.

Environmental Impact and Sustainability

High Performance Rubber offers enhanced durability and resistance to environmental degradation compared to General Purpose Rubber, resulting in longer product life cycles and reduced waste. Its formulation often incorporates eco-friendly additives and sustainable sourcing practices that minimize carbon footprint and toxic emissions. Choosing High Performance Rubber for Your applications supports sustainability goals by lowering material consumption and environmental impact throughout the product lifespan.

Choosing the Right Rubber for Your Application

High Performance Rubber offers superior resistance to extreme temperatures, chemicals, and wear, making it ideal for demanding industrial applications where durability is critical. General Purpose Rubber suits everyday uses with moderate mechanical and environmental stress, providing cost-effective flexibility and cushioning. Choosing the right rubber for your application hinges on the specific performance requirements such as temperature tolerance, chemical exposure, and mechanical stress to ensure longevity and efficiency.

High Performance Rubber vs General Purpose Rubber Infographic

libmatt.com

libmatt.com