Tackifier resin enhances adhesion and tackiness in formulations, improving the bonding strength of materials, while processing oil primarily acts as a lubricant to facilitate mixing and processing without significantly altering the adhesive properties. Your choice depends on whether you need increased stickiness or smoother processing during manufacturing.

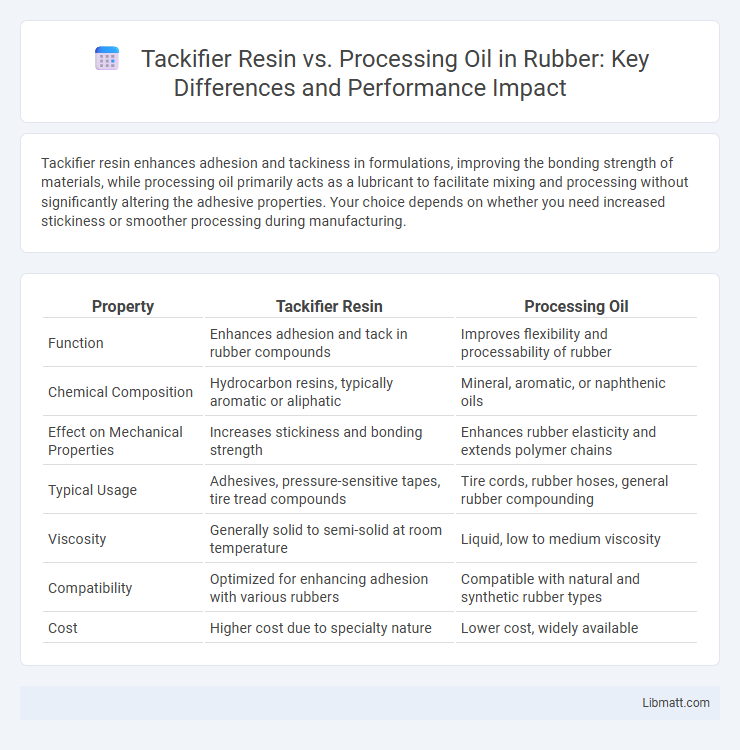

Table of Comparison

| Property | Tackifier Resin | Processing Oil |

|---|---|---|

| Function | Enhances adhesion and tack in rubber compounds | Improves flexibility and processability of rubber |

| Chemical Composition | Hydrocarbon resins, typically aromatic or aliphatic | Mineral, aromatic, or naphthenic oils |

| Effect on Mechanical Properties | Increases stickiness and bonding strength | Enhances rubber elasticity and extends polymer chains |

| Typical Usage | Adhesives, pressure-sensitive tapes, tire tread compounds | Tire cords, rubber hoses, general rubber compounding |

| Viscosity | Generally solid to semi-solid at room temperature | Liquid, low to medium viscosity |

| Compatibility | Optimized for enhancing adhesion with various rubbers | Compatible with natural and synthetic rubber types |

| Cost | Higher cost due to specialty nature | Lower cost, widely available |

Introduction to Tackifier Resin and Processing Oil

Tackifier resin is a specialty polymer used to enhance the stickiness and adhesion properties in products like adhesives, tapes, and sealants. Processing oil is a lubricant or plasticizer added to materials such as rubber and plastics to improve flexibility, processability, and softness. Understanding the differences between tackifier resins and processing oils helps optimize your formulation for better performance and durability in various industrial applications.

Key Applications in Industry

Tackifier resin is widely used in adhesives, pressure-sensitive tapes, and coatings due to its excellent tack, adhesion, and compatibility with various polymers. Processing oil primarily serves as a plasticizer and lubricant in rubber manufacturing, improving flexibility, processability, and reducing viscosity during compounding. Both materials are essential in tire production, but tackifier resins enhance grip and adhesion, while processing oils optimize the rubber's mechanical properties and ease of processing.

Chemical Composition Comparison

Tackifier resin primarily consists of hydrocarbon-based polymers such as rosin esters or hydrocarbon resins that enhance adhesive properties by increasing stickiness and tack. Processing oil is comprised of paraffinic, naphthenic, or aromatic hydrocarbons, serving as plasticizers to improve flexibility and processing of rubber compounds. Understanding the chemical differences between tackifier resin and processing oil helps you optimize formulation for targeted adhesion or flexibility in rubber manufacturing.

Functional Roles in Polymer Formulations

Tackifier resins enhance adhesive strength and cohesion in polymer formulations, improving grip and bonding performance in applications such as pressure-sensitive adhesives and rubber compounds. Processing oils act as plasticizers, increasing flexibility, processability, and compatibility of polymers by reducing viscosity and enhancing flow characteristics during manufacturing. Your choice between tackifier resin and processing oil depends on whether you need increased tackiness or improved processability in the polymer system.

Performance Characteristics

Tackifier resin enhances adhesion and tack properties in rubber and adhesive formulations, improving bonding strength and elasticity. Processing oil primarily serves to improve flexibility, processability, and softness in elastomers but does not contribute significantly to adhesive performance. Your choice depends on whether enhanced stickiness or improved processing characteristics are more critical for the specific application.

Compatibility with Base Polymers

Tackifier resins exhibit high compatibility with a wide range of base polymers such as styrenic block copolymers, natural rubber, and synthetic rubbers, enhancing adhesion and tackiness effectively. Processing oils, particularly aromatic and naphthenic types, offer excellent compatibility with elastomers and polyolefins, improving flexibility and processability without compromising polymer integrity. The choice between tackifier resin and processing oil depends on the desired balance between tack, flexibility, and polymer blend stability in applications like adhesives, sealants, and rubber compounding.

Effects on Material Properties

Tackifier resin enhances adhesion, elasticity, and thermal stability of rubber compounds, improving overall bonding strength and durability. Processing oil primarily increases flexibility, processability, and reduces viscosity, facilitating easier mixing and shaping of materials. Your choice between tackifier resin and processing oil directly impacts the balance between mechanical performance and manufacturability in rubber products.

Environmental Impact and Safety

Tackifier Resin typically presents lower environmental risks due to its stable chemical composition and reduced volatility compared to Processing Oil, which can emit harmful volatile organic compounds (VOCs) during use. Processing Oil often contains heavier hydrocarbons that may pose toxicity concerns and contribute to soil and water contamination if improperly handled. Your choice should consider the safer handling and lower environmental impact associated with Tackifier Resin, especially in applications prioritizing sustainability and worker safety.

Cost Considerations

Tackifier resins generally have a higher cost compared to processing oils due to their specialized formulation and enhanced adhesive properties. Processing oils are more economical, serving as plasticizers or softeners in rubber and polymer applications to reduce overall production expenses. Understanding these cost differences helps you make informed decisions balancing performance needs with budget constraints.

Choosing the Right Additive for Your Application

Selecting the right additive between tackifier resin and processing oil depends on the specific application requirements such as adhesive strength, flexibility, and processing conditions. Tackifier resins enhance adhesion and tack in pressure-sensitive adhesives, providing improved bonding performance and compatibility with various polymers. Processing oils improve flexibility and processability in rubber and plastic compounds by reducing viscosity and enhancing heat stability without significantly affecting adhesive properties.

Tackifier Resin vs Processing Oil Infographic

libmatt.com

libmatt.com